Tripterygium glycosides extract and its extraction process

A tripterygium wilfordii polyglycoside and a technology for an extraction method are applied in the field of plant extracts and extraction thereof, and can solve the problems of low content of medicinal components of the triptolide wilfordii polyglycoside, difficult large-scale industrial production of the process, poor product quality, and the like. It is convenient for large-scale industrial operation, high industrial application value, and the effect of improving separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

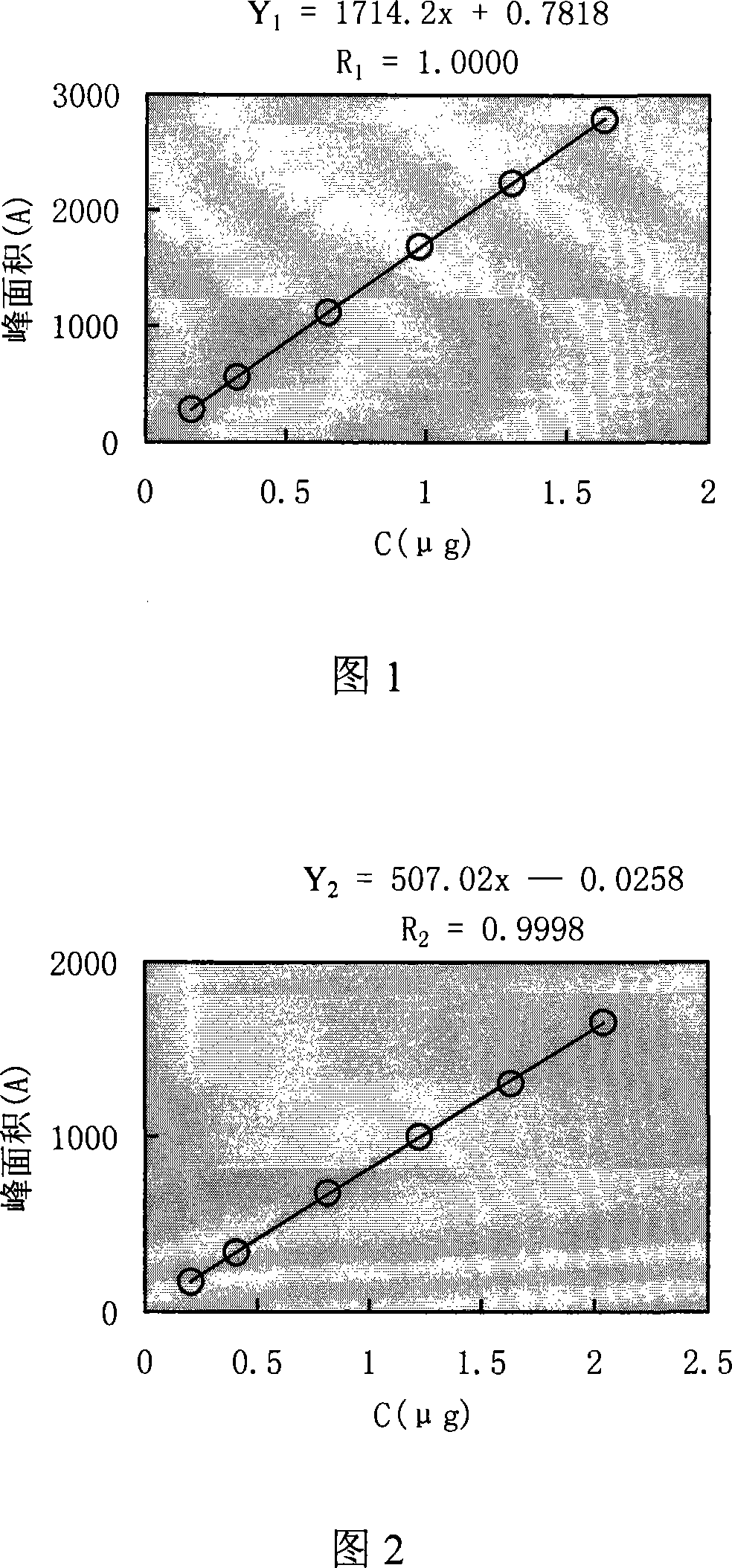

Image

Examples

Embodiment 1

[0038] The xylem of Tripterygium wilfordii is selected and processed into small pieces, and then crushed into powder by a pulverizer. Weigh 150Kg of powder, put it in a multi-purpose extraction pot, stir it evenly with 5 times the weight of water, heat it to 80°C-100°C with direct steam in the extraction pot, cook for 1 hour, cool to room temperature, and collect the filtrate. Add 6 times the weight of ethanol, soak for 8 hours, and the temperature is 30°C, release the ethanol extract, add ethanol again in the same way, soak once, and combine the extract.

[0039]Pump the extract to the distillation pot, first open the water inlet valves of the condenser and the cooler, and then slowly release the cooling water in the reaction pot, control the flow of steam and the temperature in the pot at about 70-100°C until the medicinal liquid The concentration of ethanol is less than 20% by volume.

[0040] Add chloroform equal to the volume of the concentrated solution to reflux and ex...

Embodiment 2

[0047] The xylem of Tripterygium wilfordii is selected and processed into small pieces, and then crushed into powder by a pulverizer. Weigh 150Kg of powder, put it in a multi-purpose extraction pot, stir it evenly with 3 times the weight of water, heat it to 50°C-60°C with direct steam in the extraction pot, cook for 40 minutes, cool to room temperature, and collect the filtrate. Repeat the water extraction 2 times. Add 10 times the weight of 90% methanol aqueous solution (volume percentage), soak for 24 hours at a temperature of 20° C., and release the methanol extract. Combine the extracts.

[0048] Pump the extract to the distillation pot, first open the water inlet valves of the condenser and the cooler, and then slowly release the cooling water in the reaction pot, control the flow of steam and the temperature in the pot at about 70-100°C until the medicinal liquid The concentration of methanol is less than 10% by volume.

[0049] Add 3 times the volume of the concentr...

Embodiment 3

[0055] The xylem of Tripterygium wilfordii is selected and processed into small pieces, and then crushed into powder by a pulverizer. Weigh 150Kg of powder, put it in a multi-purpose extraction pot, stir evenly with 10 times the weight of water, heat directly to 95°C-100°C in the extraction pot, cook for 30 minutes, cool to room temperature, and collect the filtrate. Repeat the water extraction 1 time. Add 6 times the weight of 40% isopropanol aqueous solution (volume percentage), soak for 15 hours, the temperature is 50°C, release the isopropanol extract, repeat the extraction twice more, and combine the extracts.

[0056] Pump the extract to the distillation pot, first open the water inlet valves of the condenser and the cooler, and then slowly release the cooling water in the reaction pot, control the flow of steam and the temperature in the pot at about 70-100°C until the medicinal liquid The concentration of isopropanol is less than 5% by volume.

[0057] Add cyclohexan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com