Preparation of multistage natural adsorbent for treating organic waste gas, and method of use

A technology of organic waste gas and adsorbents, applied in chemical instruments and methods, and other chemical processes, can solve problems such as land occupation and landscape impact, and achieve the effects of low cost, simple operation process, and rich content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

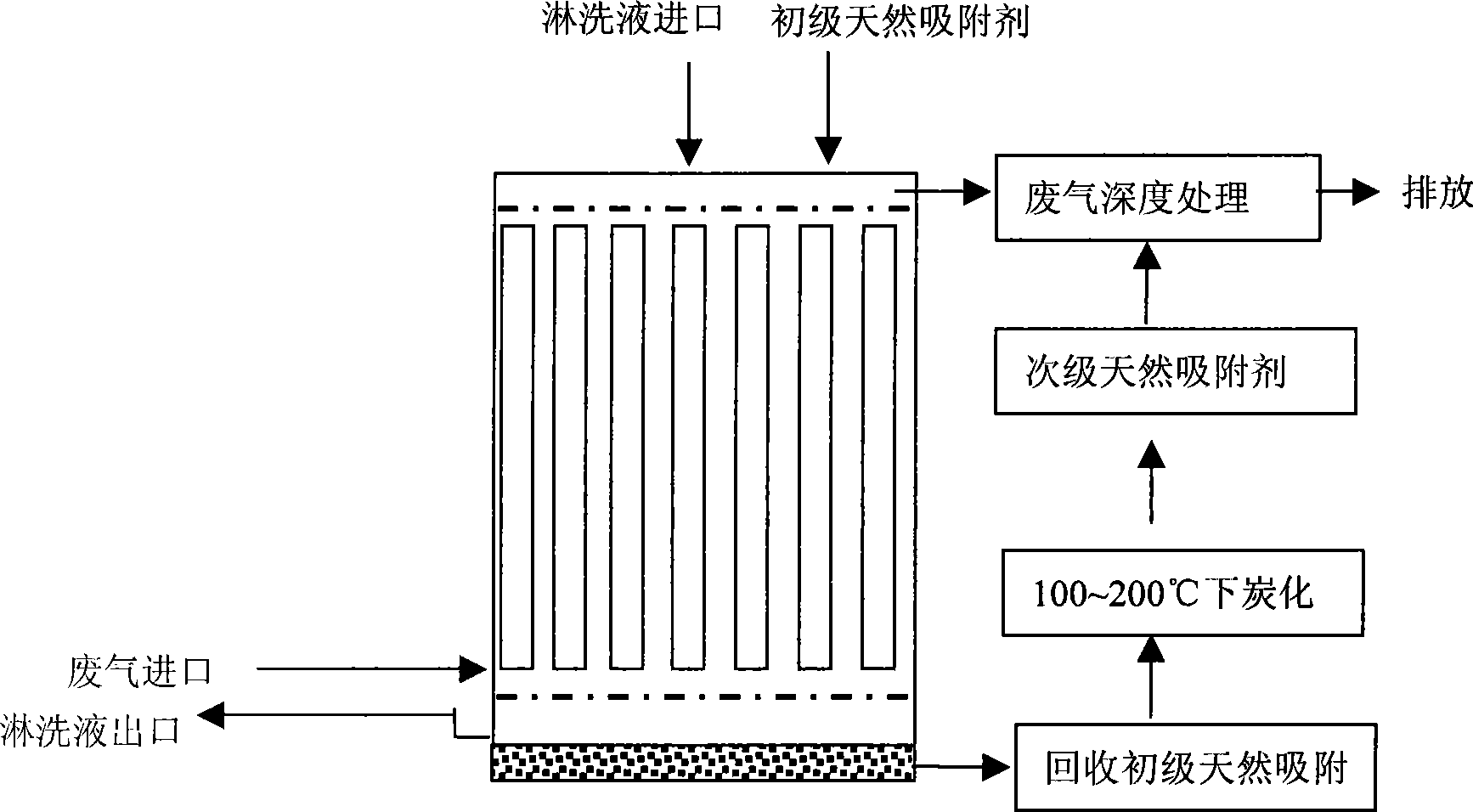

[0018] 1) Wash the discarded plant cutin, remove the remaining pulp and seed impurities, dry, pulverize, and sieve through 20 meshes to obtain a primary natural adsorbent for organic waste gas;

[0019] 2) adding the primary natural adsorbent to the eluent, the mass-volume ratio of the primary natural adsorbent to the eluent is 1:1000, after spraying, the hydrophilic and hydrophobic organic pollutants in the organic waste gas are simultaneously removed; After precipitation, the primary natural adsorbent that adsorbed organic pollutants was recovered, dried, and carbonized at 200°C for 2 hours to obtain a secondary natural adsorbent.

Embodiment 2

[0021] 1) Wash the discarded plant cutin, remove the remaining pulp and seed impurities, dry, pulverize, and sieve through 200 meshes to obtain a primary natural adsorbent for organic waste gas;

[0022] 2) adding the primary natural adsorbent to the eluent, the mass-volume ratio of the primary natural adsorbent to the eluent is 1:10000, after spraying, the hydrophilic and hydrophobic organic pollutants in the organic waste gas are simultaneously removed; After precipitation, the primary natural adsorbent adsorbed with organic pollutants was recovered, dried, and carbonized at 200°C for 6 hours to obtain a secondary natural adsorbent.

Embodiment 3

[0024] 1) Wash the discarded plant cutin, remove the remaining pulp and seed impurities, dry, pulverize, and sieve through 150 meshes to obtain a primary natural adsorbent for organic waste gas;

[0025] 2) adding the primary natural adsorbent to the eluent, the mass volume ratio of the primary natural adsorbent to the eluent is 1:8000, after spraying, the hydrophilic and hydrophobic organic pollutants in the organic waste gas are removed at the same time; After precipitation, the primary natural adsorbent adsorbed with organic pollutants is recovered, dried, and carbonized at 150° C. for 4 hours to obtain a secondary natural adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com