Gas stripping type internal circulation device, and method for recovering nitrogen, phosphor from MAP crystal

An internal circulation, air-stripping technology, applied in solution crystallization, chemical instruments and methods, phosphates, etc., can solve the problems of high cost, low recovery rate, complex recovery of nitrogen and phosphorus, and achieve less equipment and recovery rate. High, improve the effect of recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

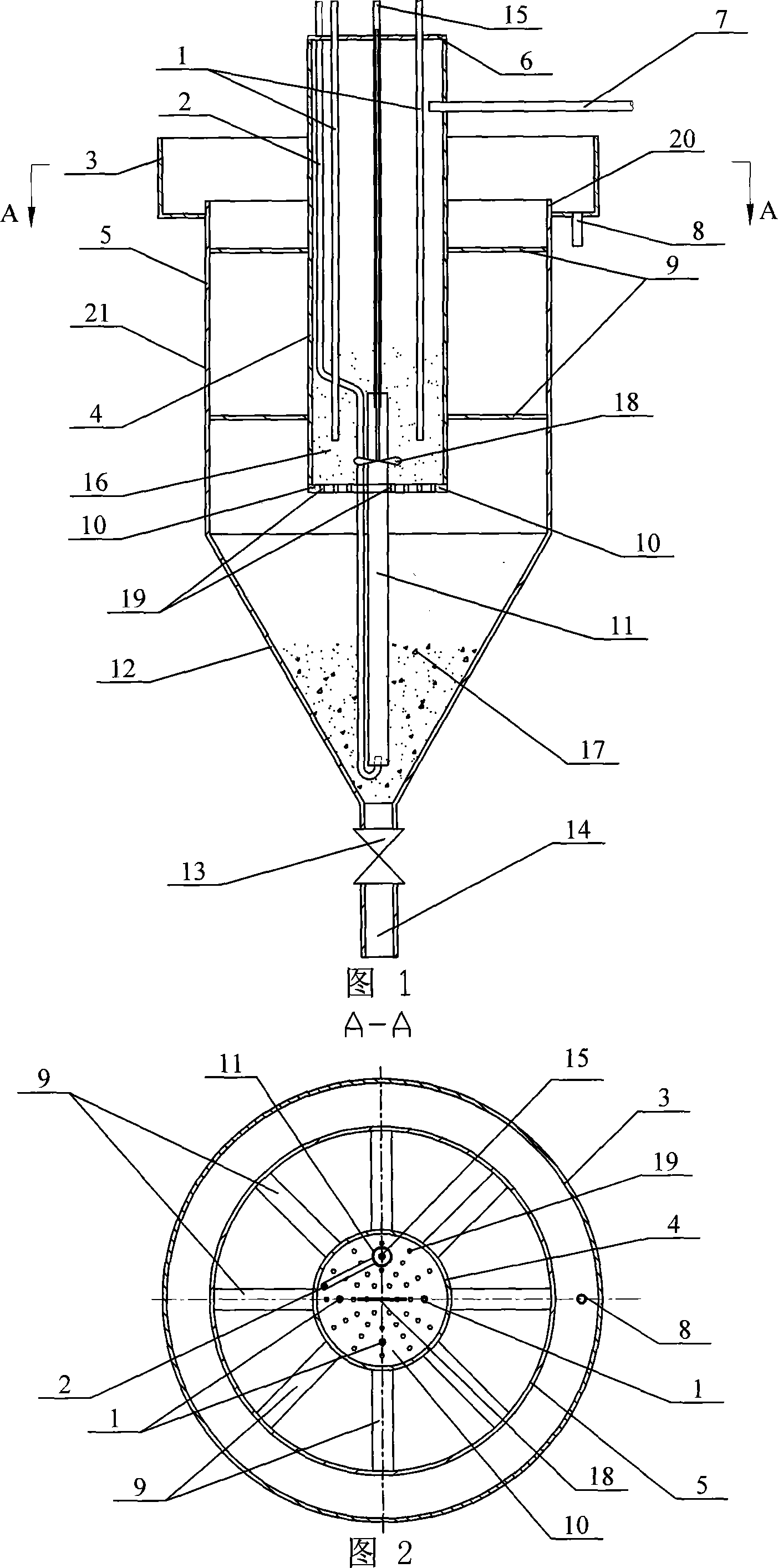

[0010] Specific embodiment one: the cylinder body 5 diameter of the airlift type internal circulation device 20 of the present embodiment is 200mm, and the total height of the device is 400mm, and it is composed of the first air inlet pipe 1, the second air inlet pipe 2, the outer sleeve 3, the inner Sleeve 4, cylinder body 5, fixed plate 6, water inlet and feed pipe 7, water outlet pipe 8, connection plate 9, isolation plate 10 with through hole 19, gas pipe 11, tapered cylinder bottom 12, equipped with The mud discharge pipe 14 of the valve 13 is composed of; the bottom of the outer sleeve 3 is fixedly connected with the upper part of the cylinder 4, an overflow weir 19 is formed between the outer sleeve 3 and the cylinder 5, and the water inlet of the drain pipe 8 is connected with the outer sleeve The water outlet at the bottom of the cylinder 3 is connected, the lower end surface of the cylinder body 5 is fixedly connected with the upper end surface of the conical cylinder...

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that the reaction device has reduced the second air inlet pipe 2 and added an agitator 17 , and the agitator 17 extends into the middle and lower part of the inner sleeve 4 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Specific embodiment three: in this embodiment, the method steps of MAP crystallization recovery nitrogen, phosphorus are as follows: will contain NH 4 + -N and PO 4 3- The waste water with a molar ratio of -P of 1 to 80:1 is passed into the air-lifting type internal circulation device 20, and then the waste water containing Mg is added. 2+ The solution makes Mg 2+ / PO 4 3- The molar ratio of -P is 1 to 3:1, and air is introduced at the same time, the volume ratio of air intake to liquid intake is 10 to 16:1, the pH value is adjusted to 8.5 to 10, the reaction is 10 to 30 minutes, and the precipitation is 1.5 to 10 hours. Magnesium ammonium phosphate crystals are obtained, that is, the nitrogen and phosphorus in the wastewater are recovered, and the product MAP or the inert substance with a particle size of 0.1-0.3mm and a large specific surface area directly enters the reaction zone through the internal circulation as a crystal nucleus.

[0014] In this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com