a use of fe 2+ Method for Improving the Stability of Continuous Dry Anaerobic Fermentation

A technology for dry anaerobic fermentation and stability, which is applied in the field of Fe2+ to improve the stability of continuous dry anaerobic fermentation. It can solve the problems of non-continuous operation, prone to acid inhibition, and high solid content, and achieve high practical application value and price. Inexpensive and effective with less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Quantitative FeCl 2 Configure Fe 2+ Concentration of 400mg / L FeCl 2 solution, ready to use. Take fresh pig manure to measure the solid content TS. According to the solid content of pig manure, add water to adjust TS to 25%, and store the rest in a constant temperature refrigerator at 4°C. Add 600mL of pig manure with a TS of 25% above into a 1L fermenter, place the fermenter in a water bath for pretreatment at a high temperature of 70°C for 1 hour, take it out and cool it to room temperature, and add the freshly prepared FeCl 2 Solution 1mL, stir evenly, add 2mL methane strain inoculum, stir evenly, pass nitrogen gas into the fermenter for 10min, exhaust the air in the fermenter, seal with rubber stopper and sealing film, collect and measure the biogas produced by fermentation with aluminum foil sampling tape.

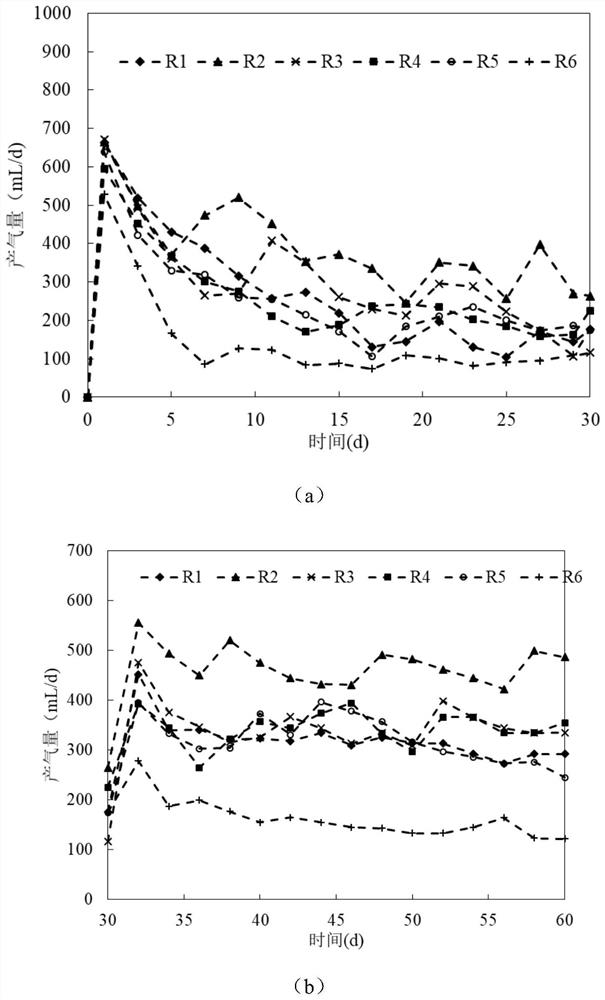

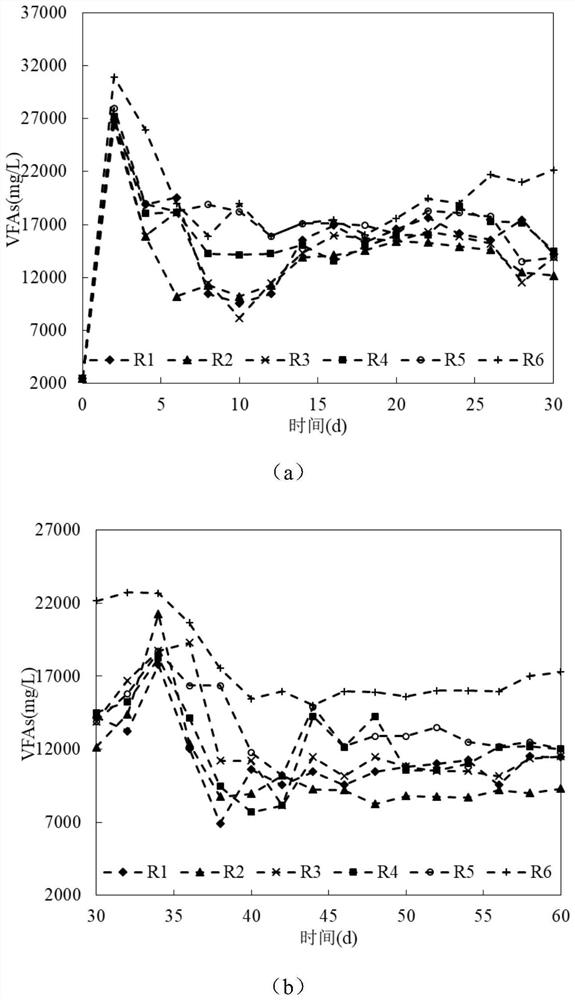

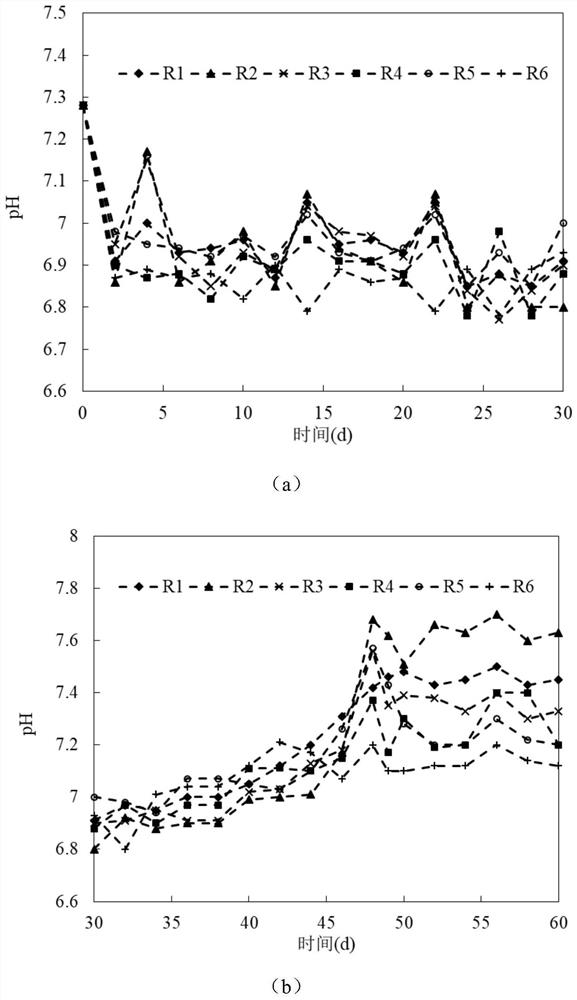

[0028] The continuous fermentation process is divided into two stages, the first stage is mesophilic fermentation, the fermentation temperature is set at 35°...

Embodiment 2

[0031] Take fresh pig manure to measure the solid content TS. According to the solid content of pig manure, add water to adjust TS to 25%, and store the rest in a constant temperature refrigerator at 4°C. Add 600mL of pig manure with TS of 25% above into a 1L fermenter, place the fermenter in a water bath at a high temperature of 70°C for 1 hour, take it out and cool it to room temperature, add 2mL of methane strain inoculum, stir well, and pour it into the fermenter Nitrogen was passed through the tank for 10 minutes, the air in the fermentation tank was exhausted, and the seal was sealed with a rubber stopper and a sealing film. The biogas produced by fermentation was collected and measured with an aluminum foil sampling tape.

[0032] The continuous fermentation process is divided into two stages, the first stage is mesophilic fermentation, the fermentation temperature is set at 35°C, and the time is 30d; the second stage is high-temperature fermentation, the fermentation te...

Embodiment 3

[0035] Quantitative FeCl 2 Configure Fe 2+ Concentration of 400mg / L FeCl 2 solution, ready to use. Take fresh pig manure to measure the solid content TS. According to the solid content of pig manure, add water to adjust TS to 25%, and store the rest in a constant temperature refrigerator at 4°C. Add 600mL of pig manure with a TS of 25% above into a 1L fermenter, place the fermenter in a water bath for pretreatment at a high temperature of 70°C for 1 hour, take it out and cool it to room temperature, and add the freshly prepared FeCl 2 Solution 1mL, stir evenly, add 2mL methane strain inoculum, stir evenly, pass nitrogen gas into the fermenter for 10min, exhaust the air in the fermenter, seal with rubber stopper and sealing film, collect and measure the biogas produced by fermentation with aluminum foil sampling tape.

[0036] The continuous fermentation process is divided into two stages, the first stage is mesophilic fermentation, the fermentation temperature is set at 35°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com