Technology of producing stevioside

A technology of steviol glycosides and production methods, which is applied in sugar production, sucrose production, sugar products, etc., can solve problems such as bitterness and astringency, and achieve the effects of clear and sweet taste, ingenious technology, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

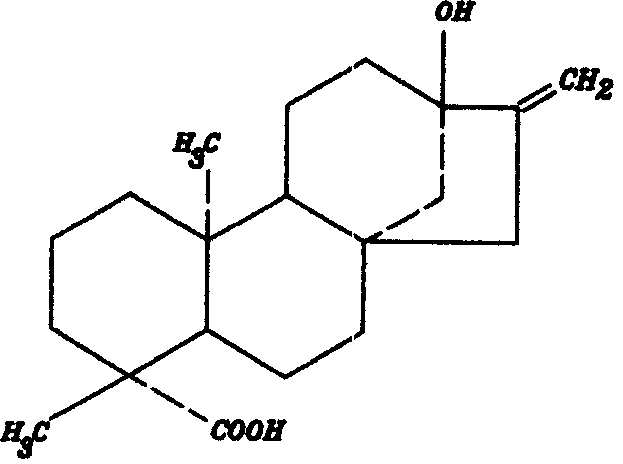

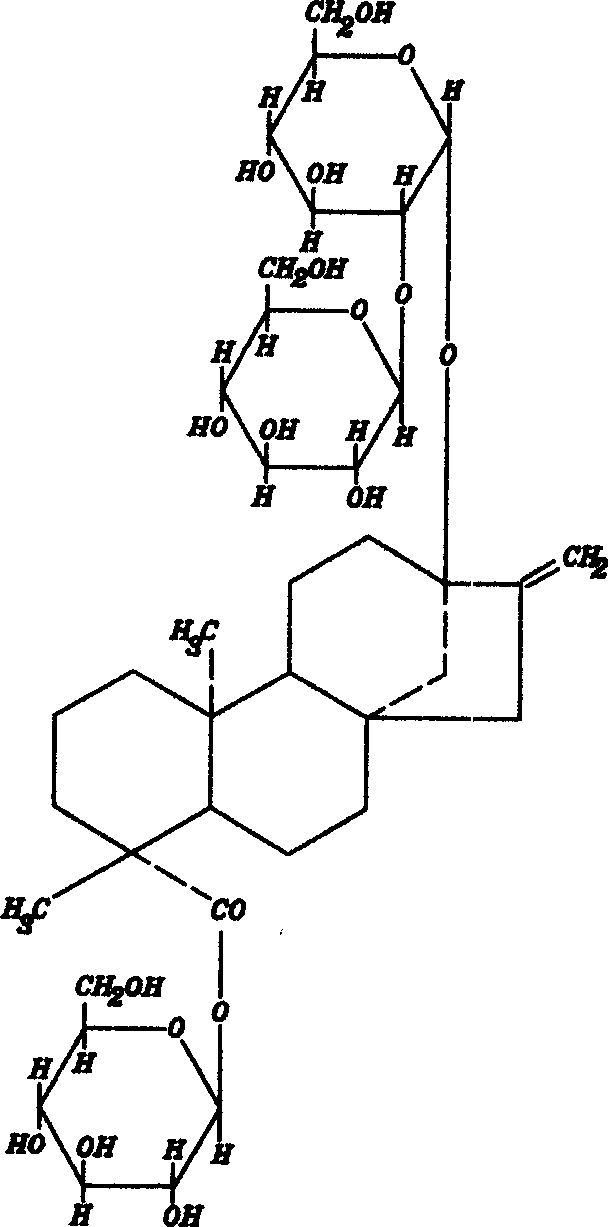

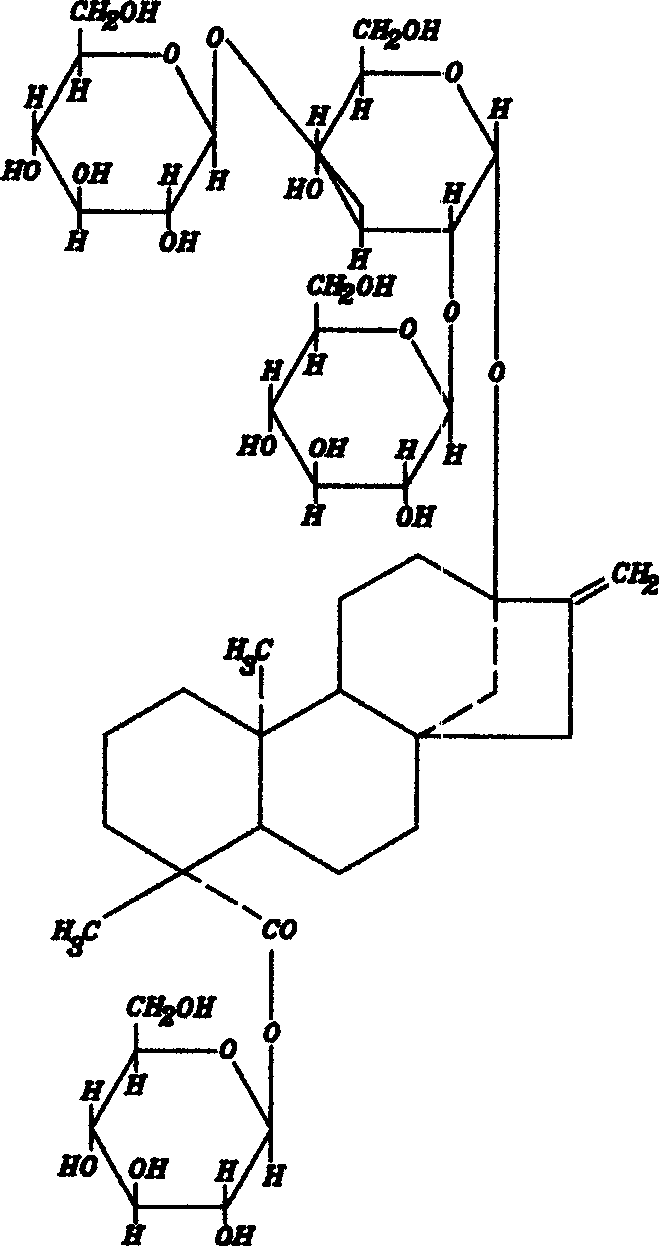

[0051] (Such as figure 1 Figure 5 As shown) a kind of steviol glycoside powder without bitter taste and its production method of the present invention adopts physical methods, and uses β-CD to contain the part of the bitter taste factor in steviol glycosides, that is, the aglycon part, thereby eliminating the bitter taste in steviol glycosides , and to achieve the above-mentioned part of the steviol glycoside containing the bitter and astringent taste factor, that is, the aglycone part, with β-CD, first, it is necessary to determine the part (glycon) and molecular structure and molecular weight of the stevioside bitter and astringent taste source, and secondly, it is necessary to estimate the glucoside The size and performance of the molecular structure of the steviol glycoside, and then equip the aglycon part and quantity of the inclusion complex β-CD inclusion steviol glycoside of the corresponding size, no matter when it is solid or in aqueous solution, so that it does not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com