Industrial production method of ovum protein polypeptide from fowl ovum by enzymatical process

A technology of egg protein polypeptide and egg protein, which is applied in the field of egg protein polypeptide industrial products, can solve the problems of difficult control of the reaction process and final products, amino acid damage, and difficult filtration, etc., and achieves improved technological content and quality, small molecular weight, and easy filter effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

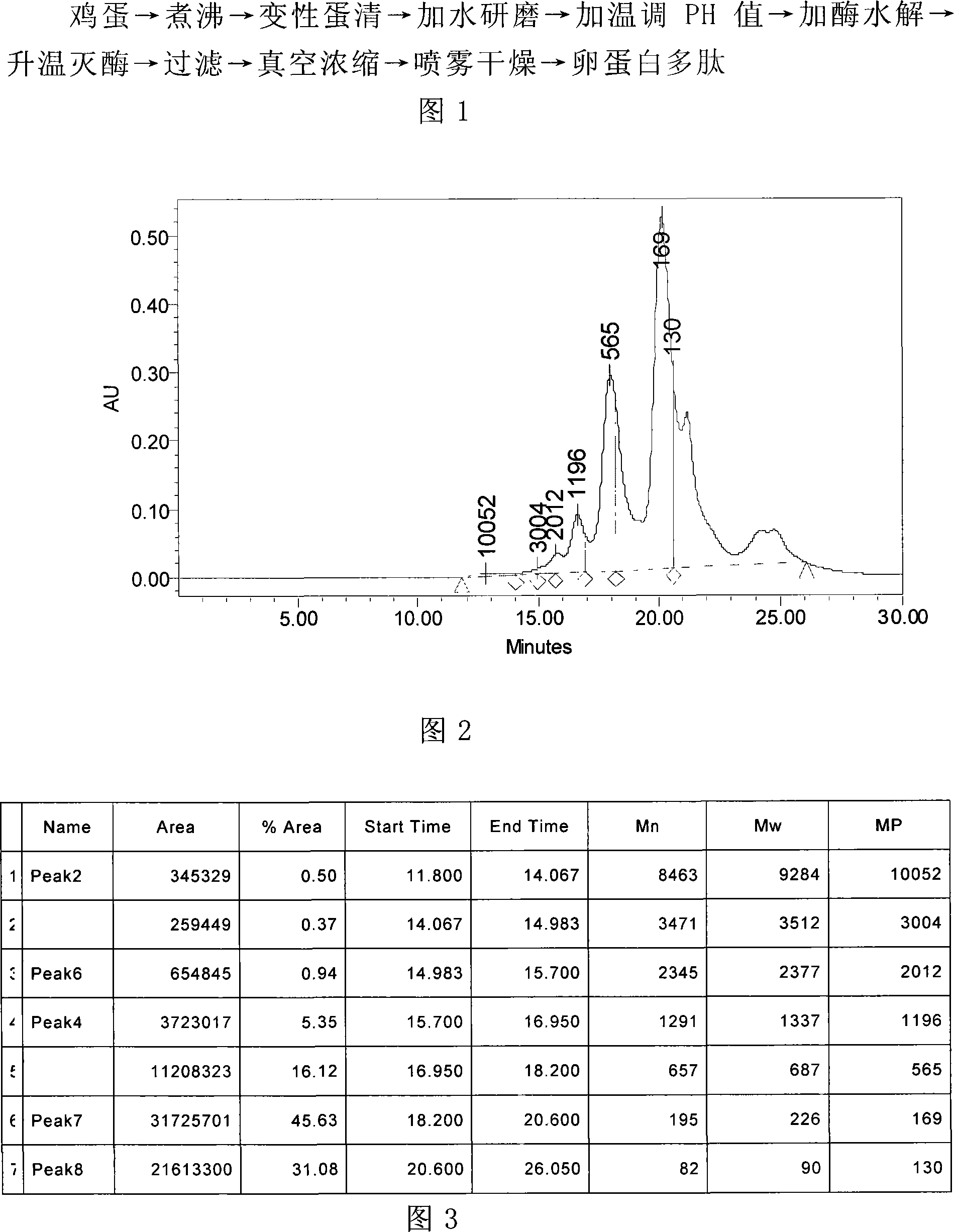

[0021] Accompanying drawing is a kind of specific embodiment of the present invention. As shown in Figure 1, this embodiment includes the following steps:

[0022] 1. Wash 10kg of eggs, put them in a cooking pot and boil them for 15-20 minutes, rinse the eggs with cold water to cool down, peel off the egg whites and set aside. Egg white weight is 5500-6000g.

[0023] 2. Add 8500-9500ml of deionized egg white to deionized water (PH value 7.5-10, conductivity ≤ 50us / cm), fully grind it with a grinder or colloid mill, and pass through a 40-60 mesh sieve.

[0024] 3. Heat the egg white aqueous solution to 50-55°C, and use 5.5-6.5ml of 30% calcium hydroxide to adjust the pH value to 7.0-7.4, add 200-300g of papain (enzyme activity 1 million u / g), enzyme powder without Dissolve 500-700ml of deionized water and add it to the feed solution to start enzymatic hydrolysis. Stir at medium temperature during this process, enzymatic hydrolysis for 0.5 hours, pH value 6.5-6.9, add calcium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com