Large area periodic array three-dimensional microstructure preparation method

A periodic array and microstructure technology, applied in microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of low production efficiency, high production cost, and complex production process of large-area three-dimensional microstructures, and achieve production Low cost, convenient production, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

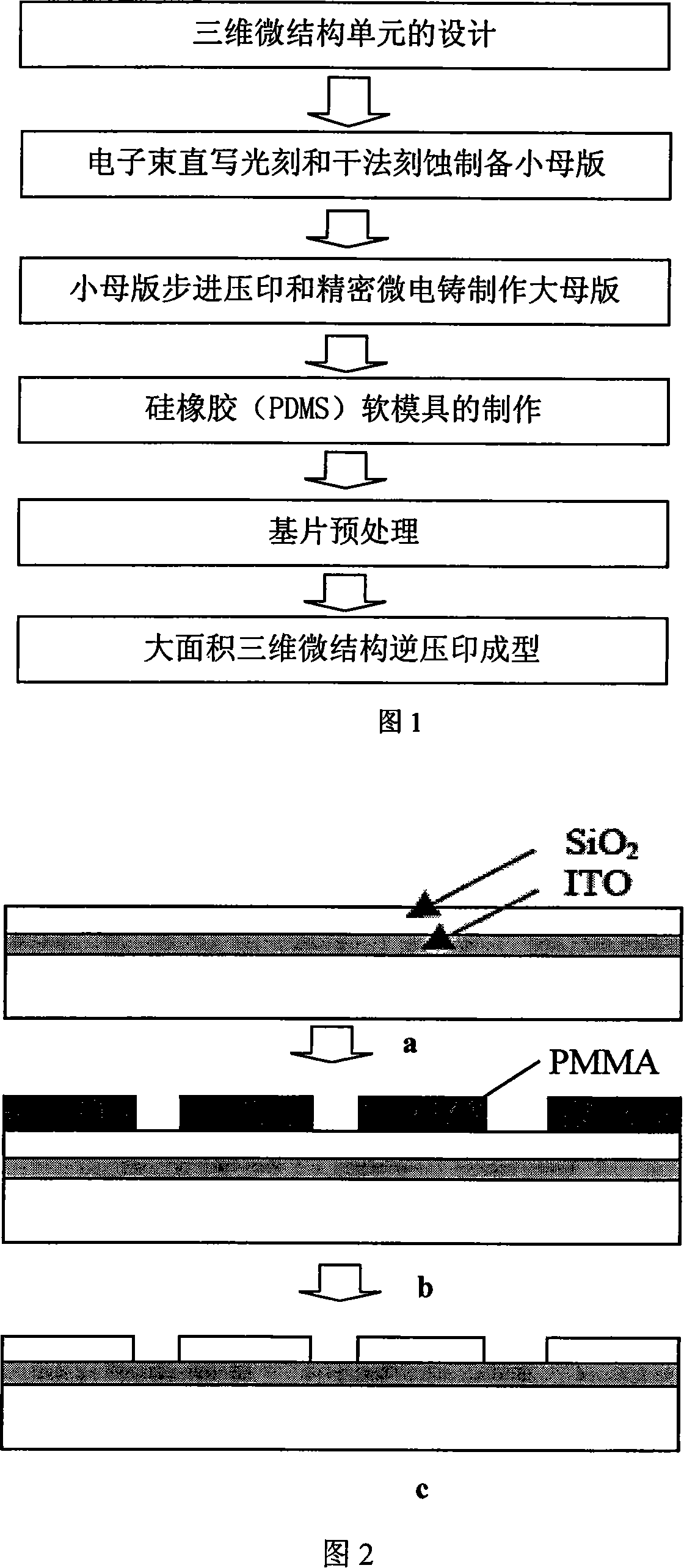

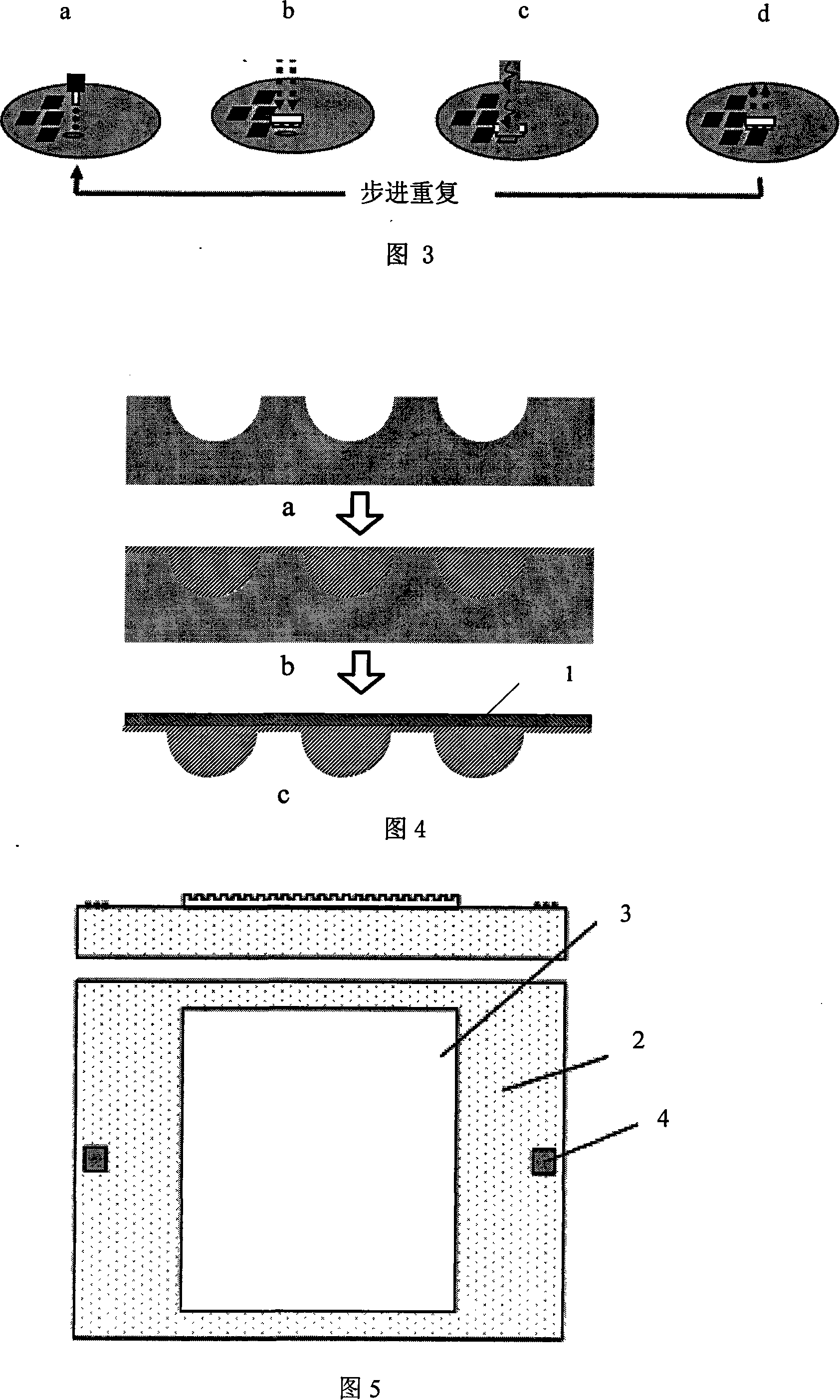

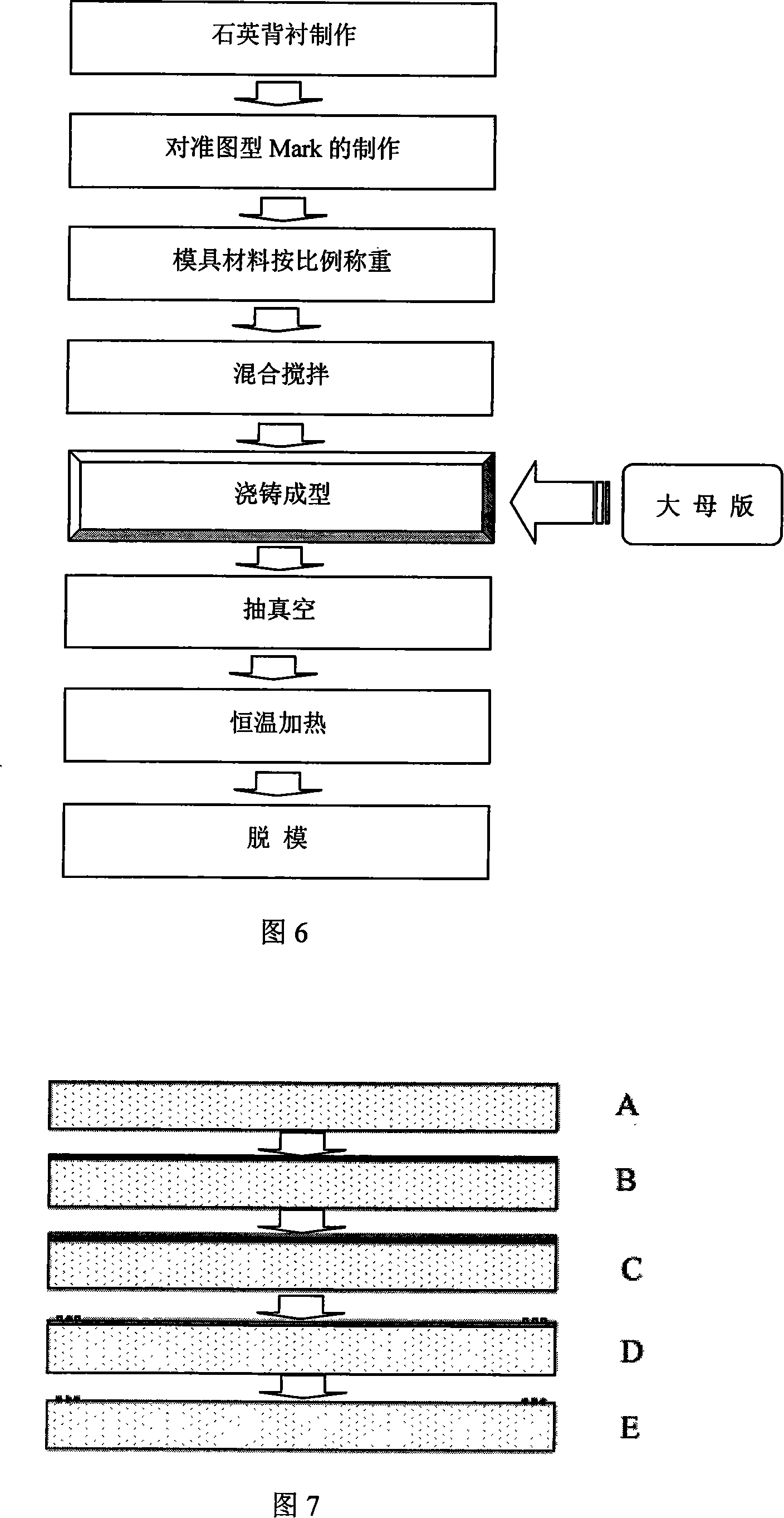

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0052]The molds used in nanoimprinting can be divided into soft molds and hard molds according to the hardness of the material. The surface energy of the hard mold material is high, which is similar to the surface energy of the cured resist, so it is prone to adhesion and difficult to release the mold. In actual use, a release agent must be sprayed on the surface of the mold, which greatly affects the imprinting efficiency. Moreover, sticking is prone to occur even if a release agent is sprayed. It is especially difficult to release large-area three-dimensional microstructures. In addition, due to the parallelism error and flatness tolerance between the substrate surface and the hard mold surface, the contact effect between the hard mold and the substrate surface is poor, and the effective area for pattern conversion is also limited. Compared with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com