Air-tight type low-voltage electrical apparatus with working contact and its oxygen-free seal method

A low-voltage electrical, air-tight technology, used in relays, electromagnetic relays, electromagnetic relay details, etc., can solve the problem of oxidation and carbon formation of working contacts, which cannot be completely solved, affect product stability and life, and cannot satisfy users. Use requirements and other issues to achieve the effect of improving the quality of the rubber seal, good sealing performance, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The airtight low-voltage electrical apparatus with working contacts of the present invention will be described in detail below in conjunction with an embodiment of the airtight non-oxidation non-flashover AC contactor of the present invention shown in the accompanying drawings.

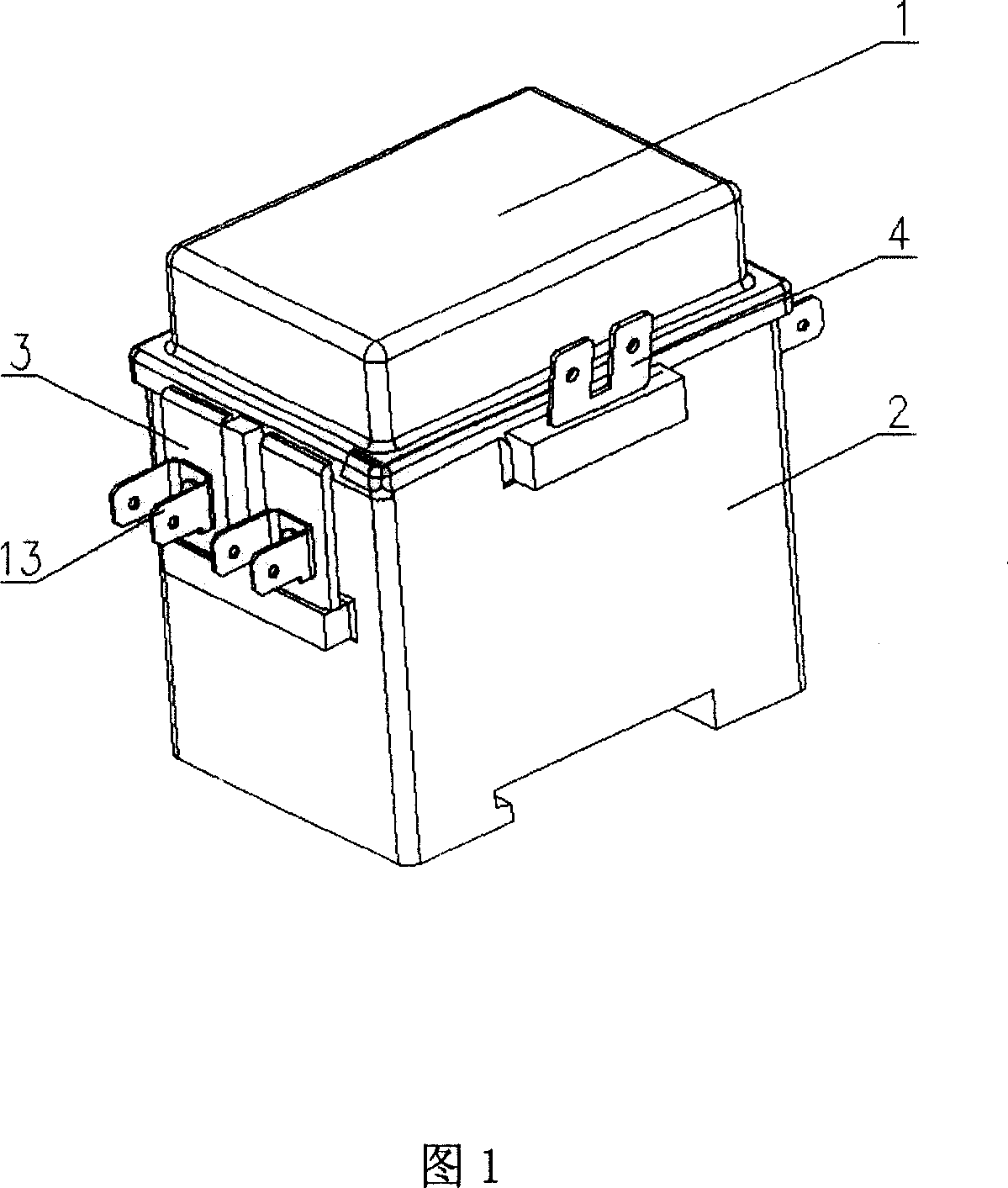

[0022] As shown in Figure 1, the airtight non-oxidation and non-flashover AC contactor of the present invention includes an airtight chamber composed of an upper cover 1 and a base 2, and a coil lead pin 4 and a static contact lead pin 13 are installed outside the airtight chamber .

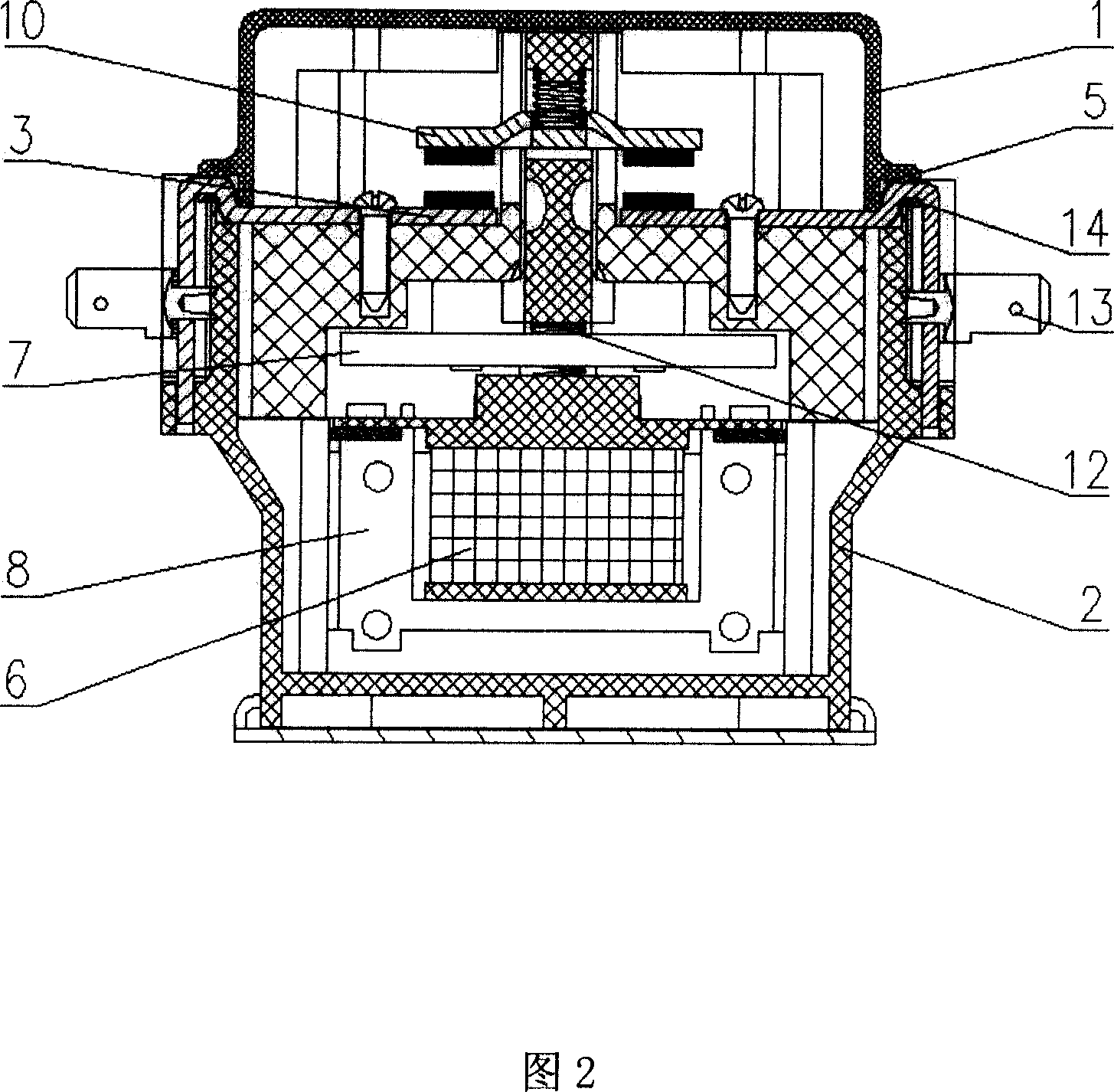

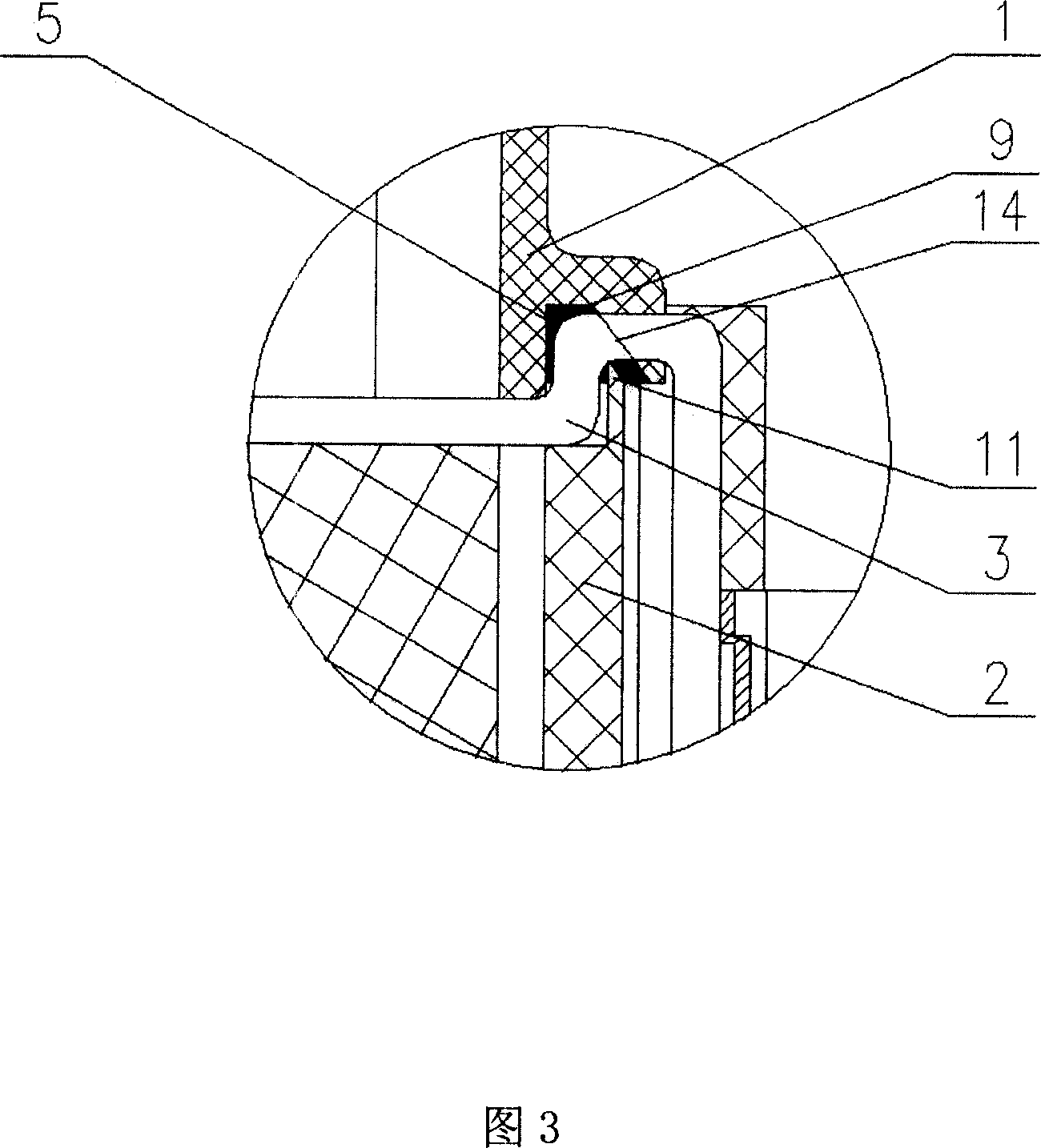

[0023] As shown in Figure 2, an electromagnetic working system is installed in the airtight chamber. The electromagnetic working system includes an armature 7, a yoke 8, and a coil 6. The yoke 8 and the electromagnetic coil 6 are installed on the base, and the armature 7 drives the contact bridge to move. . A contact working system is also installed in the airtight chamber. The contact working system includes: a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com