Pumpkin sweet-corn beverage and preparation method thereof

A sweet corn and beverage technology, applied in the field of deep processing of natural compound vegetable juice, achieves the effects of reducing processing steps, ensuring taste, and reducing sterilization intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

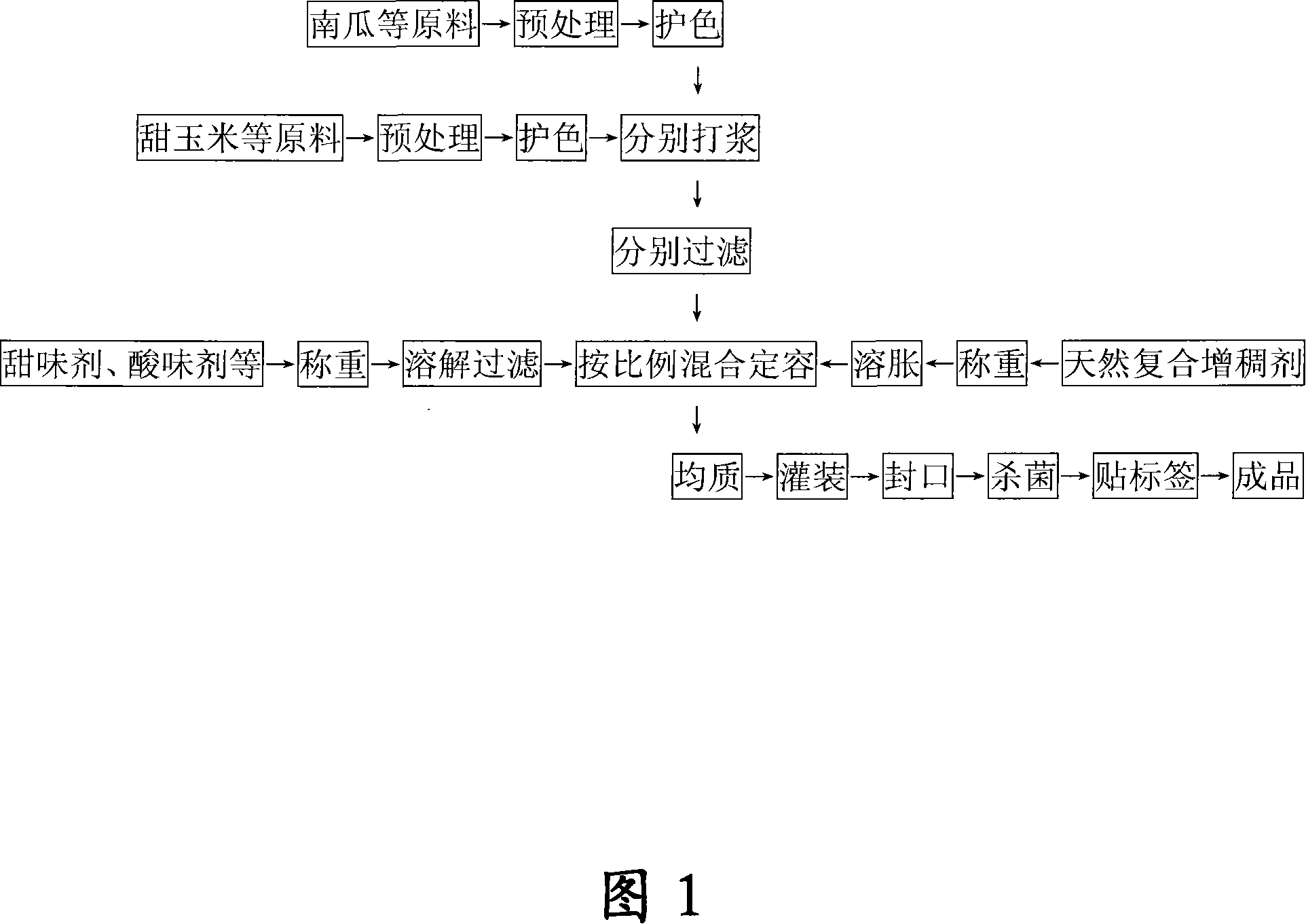

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of pumpkin, sweet corn drink product

[0037] 1% pumpkin pulp, 9% sweet corn kernels; 0.02% compound sweetener composed of sucralose and acesulfame potassium, citric acid, V C 0.25% compound sour agent; 0.1% natural compound stabilizer composed of gum arabic and xanthan gum; the rest is composed of drinking water at constant volume.

[0038] Wash and drain the high-quality pumpkins and sweet corns that have no mechanical damage, no pests, no mildew spots, and meet the processing requirements, then peel, flesh, and thresh to ensure that the materials are in blocks smaller than 2×2cm for later use.

[0039] 1. Color protection:

[0040] The finished products of the above steps are respectively placed in the cleaning pool, and 1% of the color-protecting agent is added for later use. The color-protecting agent consists of NaCl, citric acid, V C The three are combined or used alone;

[0041] 2. Crushing and beating:

[0042] The materials in...

Embodiment 2

[0051] Embodiment 2: the preparation of pumpkin, sweet corn drink product

[0052] Composed of 5% pumpkin pulp, 5% sweet corn kernels; 0.03% compound sweetener composed of stevia and acesulfame potassium; composed of V C 0.3% composite sour agent composed of malic acid; 0.25% natural composite stabilizer composed of xanthan gum and guar gum; the rest is composed of drinking water at constant volume.

[0053] Wash and drain the high-quality pumpkins and sweet corns that have no mechanical damage, no pests, no mildew spots, and meet the processing requirements, then peel, flesh, and thresh to ensure that the materials are in blocks smaller than 2×2cm for later use.

[0054] 1. Color protection:

[0055] The finished products of the above steps are respectively placed in the cleaning pool, and 0.8% of the color-protecting agent is added for subsequent use. The color-protecting agent is composed of NaCl, citric acid, V C The three are combined or used alone;

[0056] 2. Crushin...

Embodiment 3

[0066] Embodiment 3: the preparation of pumpkin, sweet corn drink product

[0067] 3% of pumpkin pulp, 7% of sweet corn kernels; 0.05% compound sweetener composed of acesulfame potassium and aspartame; composed of citric acid, V C 0.15% compound sour agent with malic acid; 0.15% natural compound stabilizer composed of gum arabic, xanthan gum and guar gum; the rest is composed of drinking water at constant volume.

[0068] Wash and drain the high-quality pumpkins and sweet corns that have no mechanical damage, no pests, no mildew spots, and meet the processing requirements, then peel, flesh, and thresh to ensure that the materials are in blocks smaller than 2×2cm for later use.

[0069] 1. Color protection:

[0070] The finished products of the above steps are respectively placed in the cleaning pool, and 0.5% of the color-protecting agent is added for later use. The color-protecting agent consists of NaCl, citric acid, V C The three are combined or used alone;

[0071] 2. C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com