Method of preparing apolipoprotein A-I

An apolipoprotein and A-I technology, which is applied in the preparation methods of peptides, apolipoproteins, chemical instruments and methods, etc., can solve the problems such as being unsuitable for large-scale production of enterprises, high equipment requirements, and resource shortages, and achieve a comprehensive The effect of utilization, low equipment requirements, and blood resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

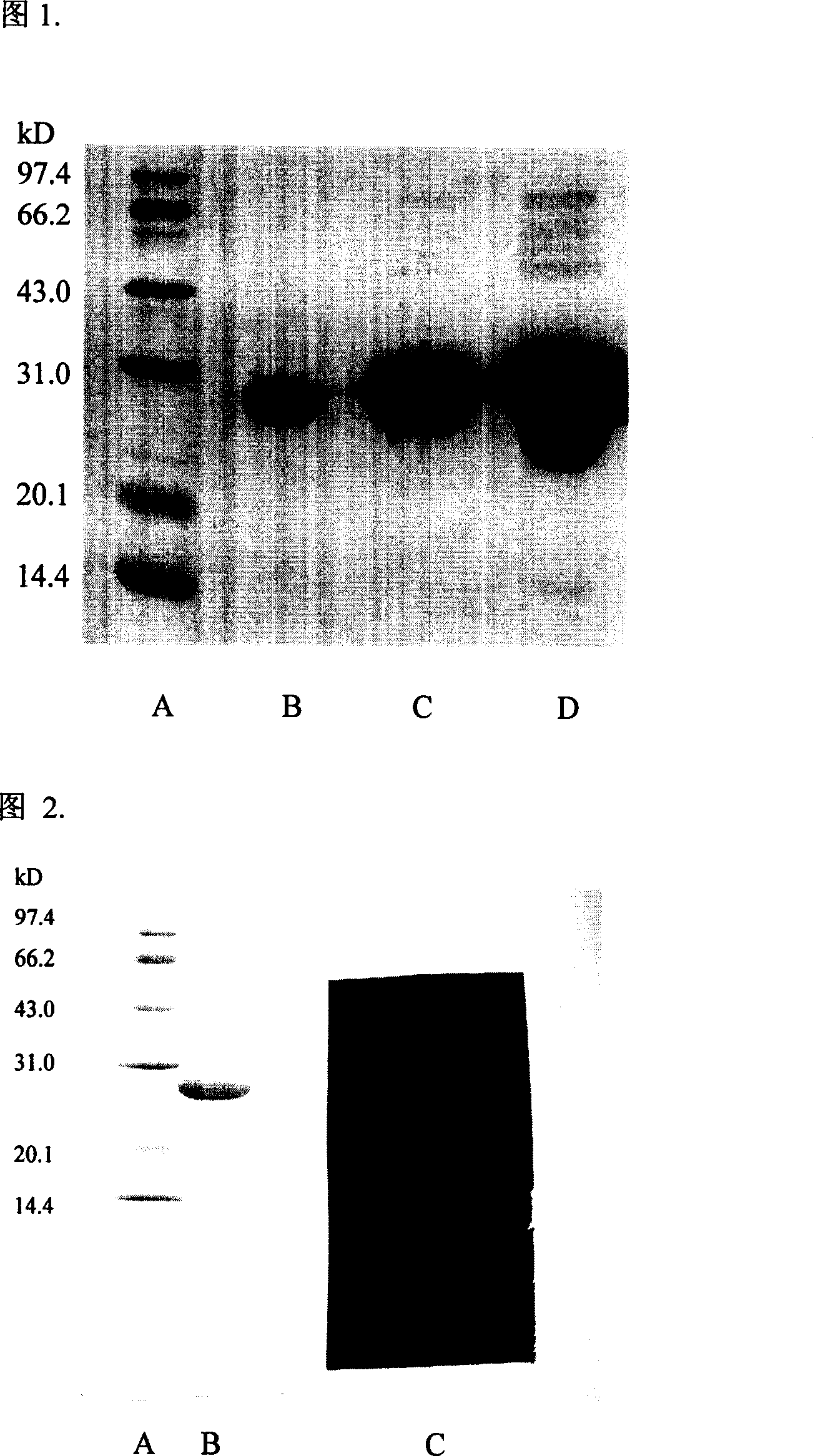

Embodiment 1

[0048] 30g F-IV plus 120mL 65% ethanol-10mM NaHCO 3 (pH7.3) solution, stirred at -20°C for 2 hours, centrifuged to separate the supernatant, adjusted the pH of the supernatant to 5.5, centrifuged to separate the precipitate, and the precipitate was completely dissolved in 50mL 100mM Tris-HCl-6M Urea (pH8.6) solution. Add an equal volume of -20°C pre-cooled chloroform / ethanol (1:1) solution, shake evenly, and let stand at -20°C for 2h. Centrifuge, take the supernatant, add an equal volume of -20°C pre-cooled ethanol, shake evenly, let stand at -20°C for 2 hours, and centrifuge to separate the supernatant. The supernatant was concentrated and dialyzed against carbonate buffer (20 mM), pasteurized, sterilized and filtered, and freeze-dried to obtain ApoA-I dry powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com