Metallic film test piece and its preparing method for estimating and screening museum exhibition stuff

A metal film and museum technology, applied in the preparation of test samples, analysis materials, measuring devices, etc., can solve the problem of affecting the smoothness and flatness of the metal test piece surface, affecting the evaluation results of cultural relics collection and exhibition materials, and the loss of metal raw materials, etc. problem, to achieve the effect of shortening the evaluation time, convenient and effective standardization, and reducing the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

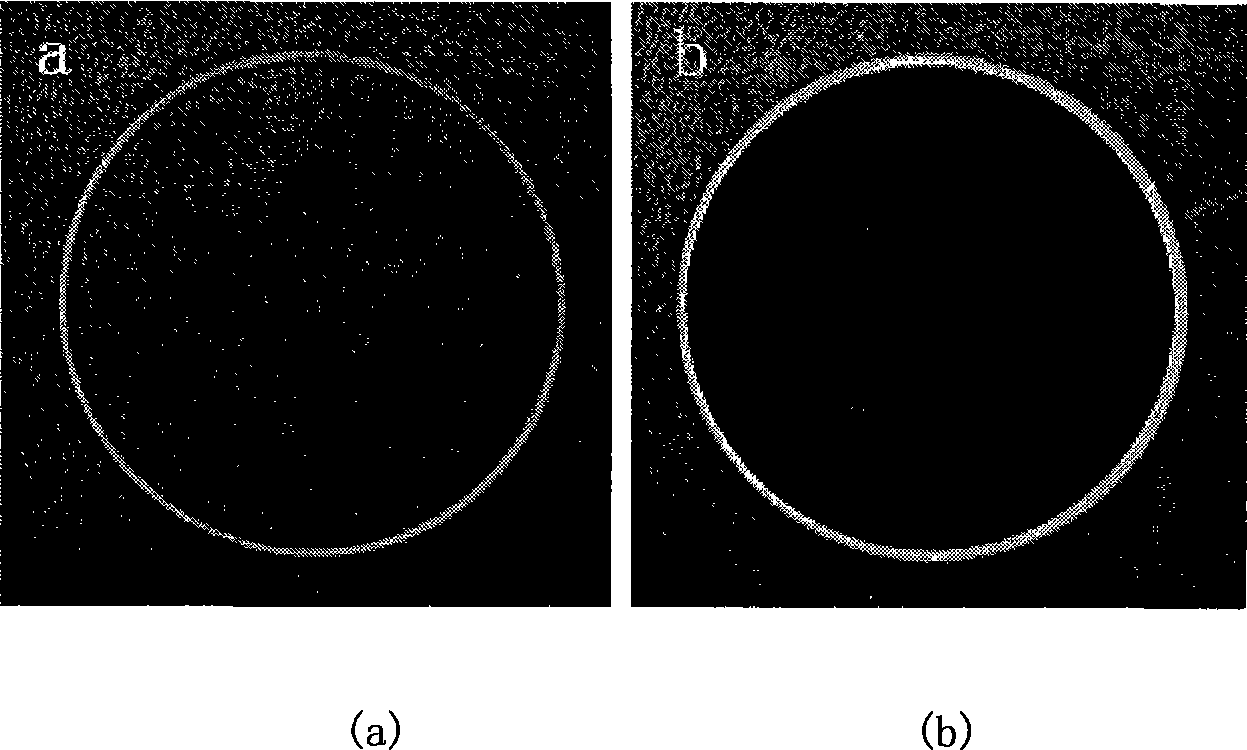

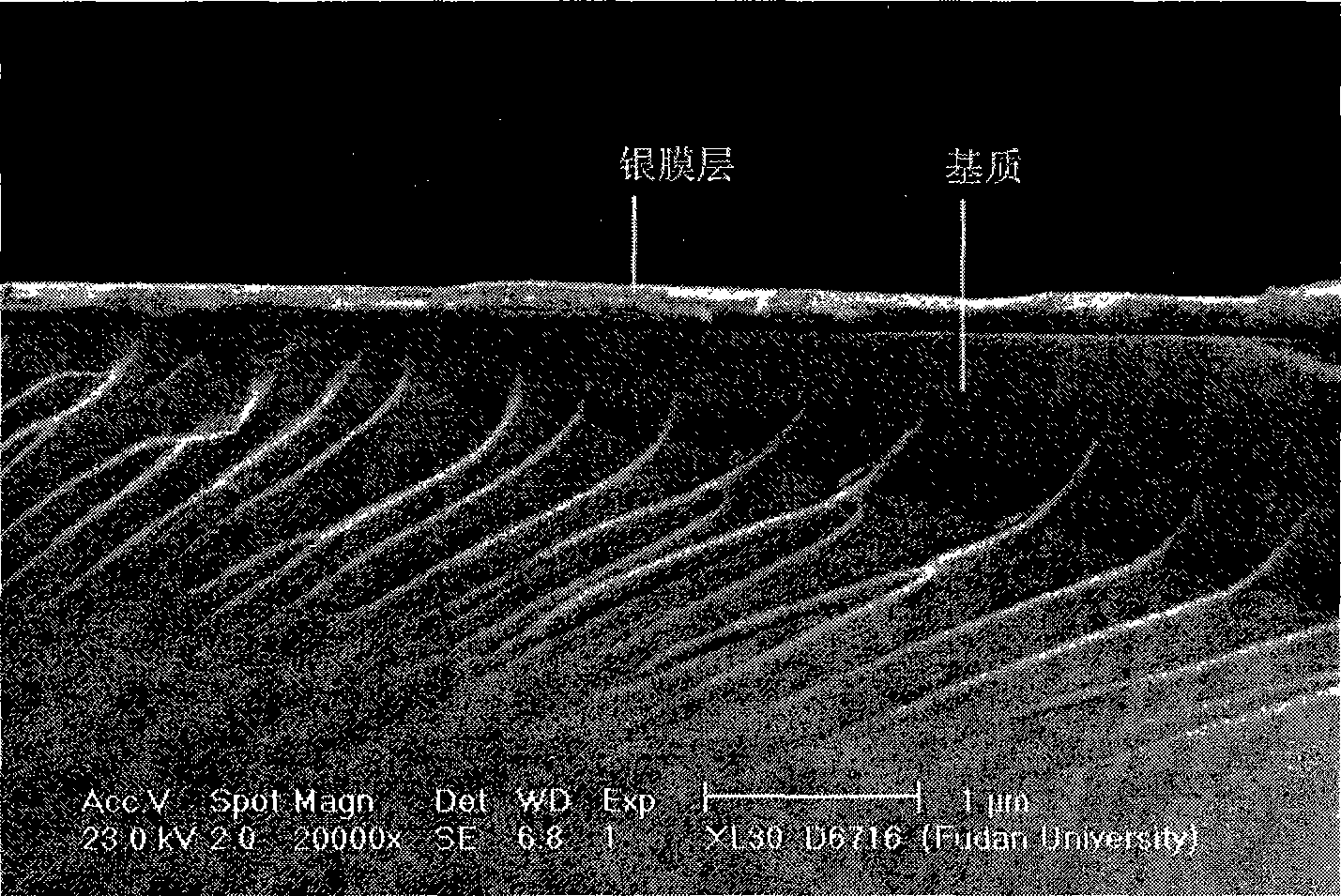

[0030] Substrate: glass disc

[0031] Coating target material: silver with a purity of ≥99.9%

[0032] Coating equipment: Take the DMD-450 optical multilayer coating machine produced by Beijing Instrument Factory as an example

[0033]Film thickness control: 0.4g / 100 glass discs

[0034] Plating process: open the vacuum chamber of the coating machine, stick 100 pieces of glass discs on the special bracket of the coating machine through high-temperature tape, put them into the coating machine after cleaning the surface, and put 0.4g of silver with a purity of ≥99.9% In evaporation parts. Close the vacuum chamber and evacuate to 1×10 -5 Torr, and then start evaporation. The coating time is about 30-60 minutes. After opening the vacuum chamber, the prepared test pieces can be removed and vacuum packed. The thickness of the deposited film is about 100-200nm.

Embodiment 2

[0036] Substrate: glass disc

[0037] Coating target material: silver with a purity of ≥99.9%

[0038] Coating equipment: Take the DMD-450 optical multilayer coating machine produced by Beijing Instrument Factory as an example

[0039] Film thickness control: 0.6g / 100 glass discs

[0040] Plating process: open the vacuum chamber of the coating machine, stick 100 pieces of glass discs on the special bracket of the coating machine through high-temperature tape, put them into the coating machine after cleaning the surface, and put 0.6g of silver with a purity of ≥99.9% In evaporation parts. Close the vacuum chamber and evacuate to 1×10 -5 Torr, and then start evaporation. The coating time is about 30-60 minutes. After opening the vacuum chamber, the prepared test pieces can be removed and vacuum packed. The thickness of the coated film is about 200nm.

Embodiment 3

[0042] Substrate: plastic sheet

[0043] Coating target material: silver with a purity of ≥99.9%

[0044] Coating equipment: Take the DMD-450 optical multilayer coating machine produced by Beijing Instrument Factory as an example

[0045] Film thickness control: 0.6g / 100 plastic sheets

[0046] Plating process: open the vacuum chamber of the coating machine, stick 100 pieces of plastic sheets on the special bracket of the coating machine through high-temperature tape, put them into the coating machine after cleaning the surface, and put 0.6g of silver with a purity of ≥99.9% in the Parts for evaporation. Close the vacuum chamber and evacuate to 1×10 -5 Torr, and then start evaporation. The coating time is about 30-60 minutes. After opening the vacuum chamber, the prepared test pieces can be removed and vacuum packed. The thickness of the coated film is about 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com