Vulcanized rubber regeneration activator and preparation method and uses thereof

A compound and reaction kettle technology, applied in the application field of vulcanized rubber regeneration, can solve the problems of low production cost of reclaimed rubber, high production cost of reclaimed rubber, poor infiltration penetration, etc., achieve significant economic and social benefits, and accelerate thermal oxidation. The rate of degradation, the effect of enhancing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

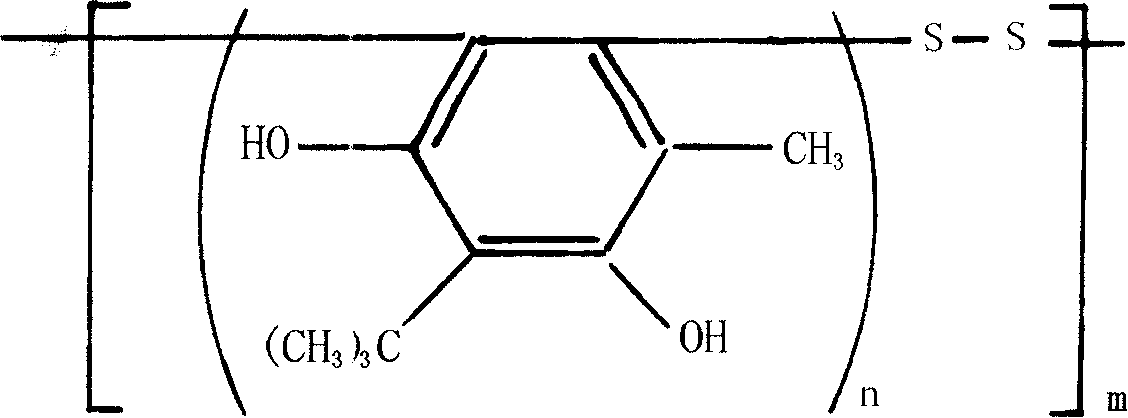

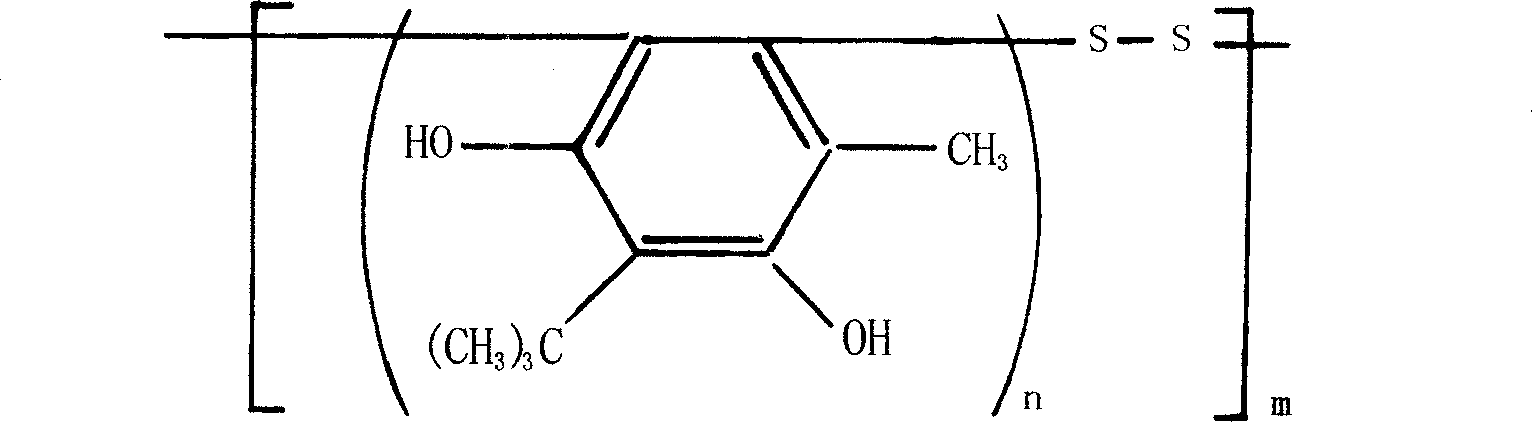

[0033] Preparation of 2-tert-butyl-p-methylresorcinol polysulfide compound (B-450 vulcanized rubber regeneration activator)

[0034] Put 100 kg of sulfur into the airtight reactor, open the bottle of liquid chlorine, pour 100 kg of chlorine gas into the reactor, heat and stir to obtain the intermediate sulfur monochloride;

[0035] Add 1 ton of oily by-products from the production of 168 antioxidants into the warming tank, heat them with steam to melt them, pump them into the reactor with a vacuum pump, heat, and vacuum dehydrate to obtain intermediate product B;

[0036] Put the prepared intermediate product B into the reaction kettle, keep the temperature to 75 degrees, stir, slowly add 200 kg of sulfur monochloride; after 30 minutes, vacuumize, continue to stir and react for 15 minutes; then heat to 150 degrees; add the catalyst concentration 3 kg of 98% concentrated sulfuric acid solution, add 200 kg of ZR-1 resin toughening agent while stirring, continue to react at high temp...

Embodiment 2

[0038] Preparation of 2-tert-butyl-p-methylresorcinol polysulfide compound (B-450 vulcanized rubber regeneration activator)

[0039] Put 500 kg of sulfur into the airtight reactor, open the bottle of liquid chlorine, pour 500 kg of chlorine into the reactor, heat and stir to obtain the intermediate sulfur monochloride;

[0040] Add 5 tons of oily by-products from the production of 501 antioxidant to the temperature tank, heat it with steam to melt it, pump it into the reactor with a vacuum pump, heat it, and vacuum dehydrate to obtain intermediate product B.

[0041] Put the prepared intermediate product B into the reaction kettle, keep the temperature at 75 degrees, stir, slowly add 1 ton of sulfur monochloride; after 30 minutes, vacuumize, continue to stir and react for 15 minutes; then heat up to 115 degrees; add a concentration of 98 % Concentrated sulfuric acid solution 15 kg, add 1 ton of ZR-4 resin toughening agent while stirring, continue to react at high temperature for 2 h...

Embodiment 3

[0043] Application of 2-tert-butyl p-methylresorcinol polysulfide compound (B-450 vulcanized rubber regeneration activator) in reclaimed rubber

[0044] Waste rubber raw materials: mixed waste rubber of butyl rubber, EPDM rubber, styrene butadiene rubber, nitrile rubber and other synthetic rubbers; rubber powder particle size 16 mesh.

[0045] The dosage of 2-tert-butyl-p-methylresorcinol polysulfide compound (B-450 vulcanized rubber regeneration activator) of the product of the present invention: 0.03% of the weight of the waste rubber raw material.

[0046] Recycled rubber quality: tensile strength (MPa) 11.2; elongation at break above 430;

[0047] Features: The waste rubber powder has a large particle size and can still produce fine reclaimed rubber, which reduces the electricity cost per ton of reclaimed rubber by 120 yuan. In the production process, compared with the traditionally used polyalkylphenol disulfide trade name 420 rubber regeneration activator, rosin is omitted a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com