Post-decoration method for dye sensitization light anode of dye sensitization solar battery

A technology for solar cells and dye sensitization, applied in the field of designing dye-sensitized solar cell materials, can solve the problems of easily corroded electrodes, battery performance decline, dye desorption, etc., to achieve improved open circuit voltage and short circuit current, enhanced stability, Reduce the effect of reverse compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

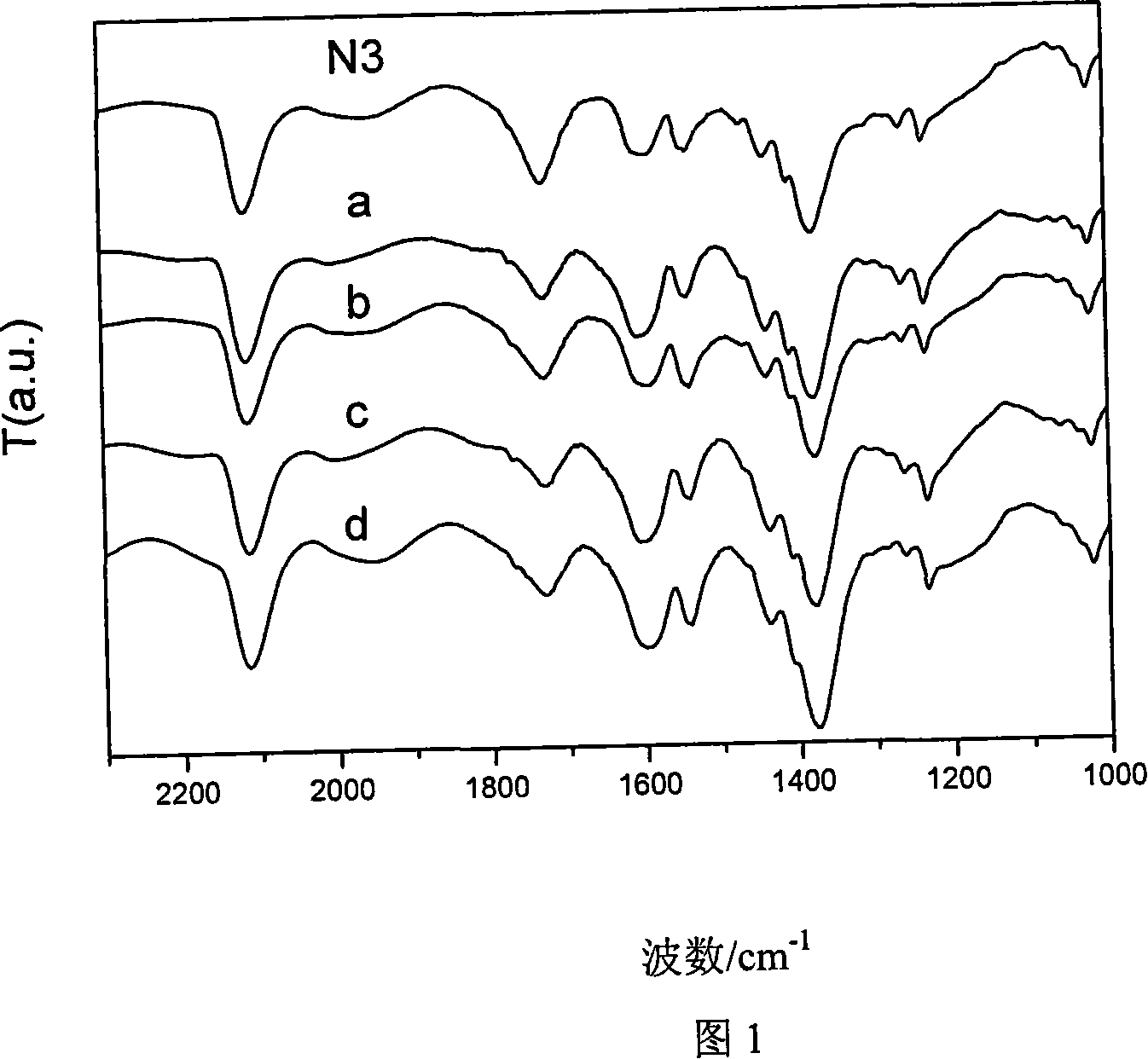

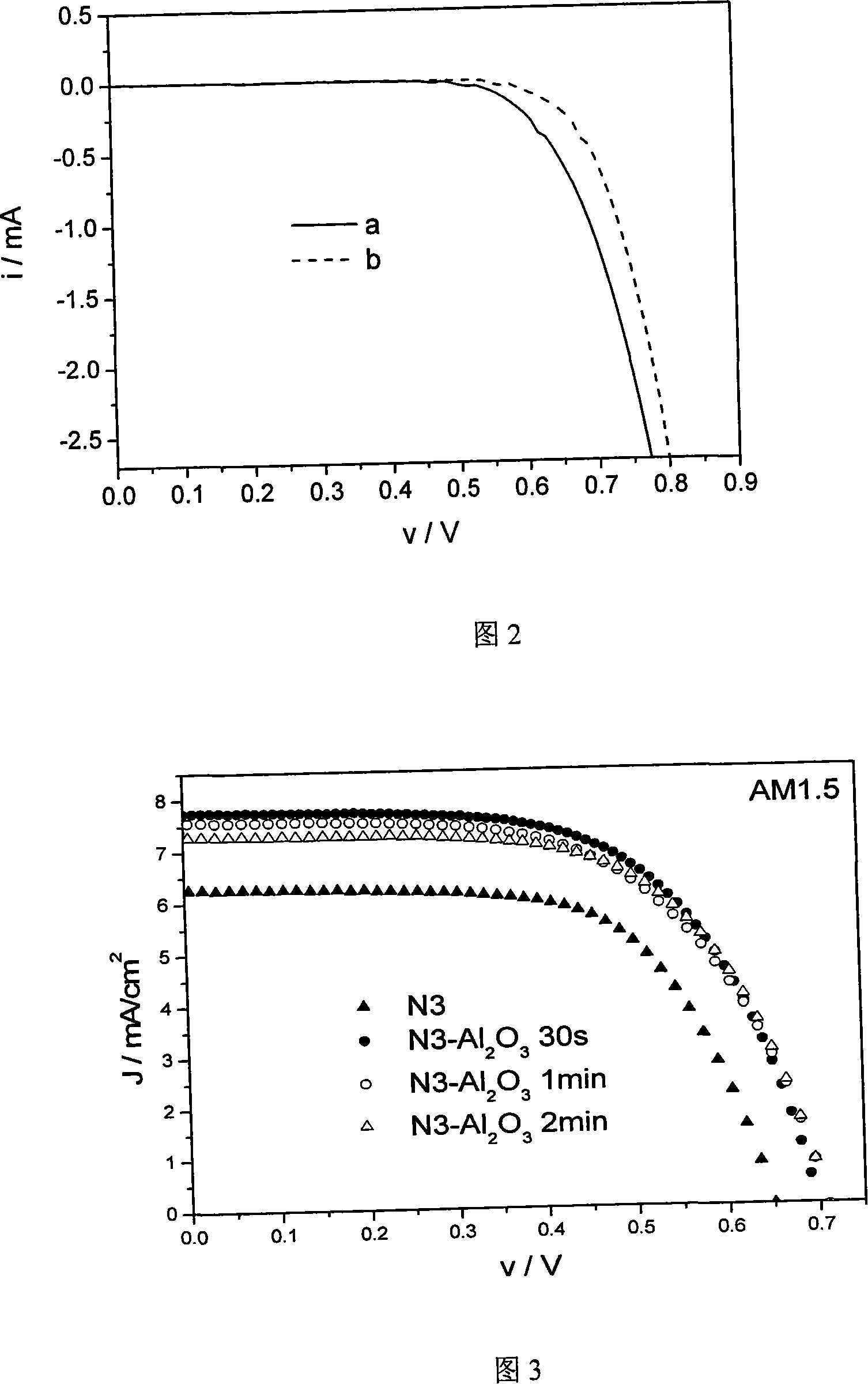

[0026] Example 1: Use titanium dioxide colloid to scratch the film on the transparent conductive glass ITO, sinter at 450 ° C for 30 minutes to obtain a nanoporous structure wide bandgap semiconductor titanium dioxide film, then soak it in 5 mm0l / L dye solution for 30 minutes, take it out and rinse it with absolute ethanol , the TiO 2 Porous membrane in 0.015mol / L Al[OCH(CH 3 ) 2 ] 3 / isopropanol solution for 30s, rinsed with ethanol, dried in the air, and placed in the air for 1 hour to obtain a dye-sensitized photoanode. A quasi-solid electrolyte is used, and a platinum-plated conductive glass is used as a counter electrode to assemble a battery. at 100mW / cm 2 Under white light irradiation, the measured open circuit voltage of the battery is 0.70V, and the short circuit current is 7.72mA / cm 2 , the fill factor is 61.3%, and the total photoelectric conversion efficiency is 3.32%.

example 2

[0027] Example 2: Use titanium dioxide colloid to scrape the film on the transparent conductive glass ITO, sinter at 450 ° C for 30 minutes to obtain a nanoporous structure wide bandgap semiconductor titanium dioxide film, then soak it in 5 mmol / L dye solution for 24 hours, take it out with absolute ethanol Rinse, this TiO 2 Porous membrane in 0.5mol / L Ga(H 2 PO 2 ) 3 / isopropanol solution for 15 minutes, rinsed with ethanol, dried in the air, and placed in the air for 1 hour to obtain a dye-sensitized photoanode. A quasi-solid electrolyte is used, and a platinum-plated conductive glass is used as a counter electrode to assemble a battery. at 100mW / cm 2 Under the simulated sunlight, the measured open circuit voltage of the battery is 0.68V, and the short circuit current is 7.24mA / cm 2 , the fill factor is 63.9%, and the total photoelectric conversion efficiency is 3.15%.

example 3

[0028] Example 3: Use titanium dioxide colloid to scrape the film on the transparent conductive glass ITO, sinter at 450 ° C for 30 minutes to obtain a nanoporous structure wide bandgap semiconductor titanium dioxide film, then soak it in 5 mmol / L dye solution for 12 hours, take it out with absolute ethanol Rinse, this TiO 2 Porous membrane in 1mol / L Ti(OC 4 h 9 ) / butanol solution for 2 min, rinsed with ethanol, dried in the air, and placed in air for 1 hour to obtain a dye-sensitized photoanode. A quasi-solid electrolyte is used, and a platinum-plated conductive glass is used as a counter electrode to assemble a battery. at 100mW / cm 2 Under white light irradiation, the measured open circuit voltage of the battery is 0.713V, and the short circuit current is 7.18mA / cm 2 , the fill factor is 64.9%, and the total photoelectric conversion efficiency is 3.32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short circuit current | aaaaa | aaaaa |

| Short circuit current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com