Efficient crystalline silicon solar cell and production method thereof

A solar cell and crystalline silicon technology, applied in the field of solar cells, can solve the problems of inability to form ohmic contact between silver grid lines and silicon, low filling factor, and reduced phosphorus doping concentration, so as to improve photoelectric conversion efficiency, increase open circuit voltage and Effect of short circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

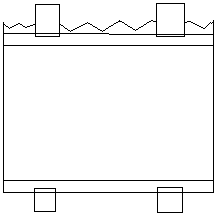

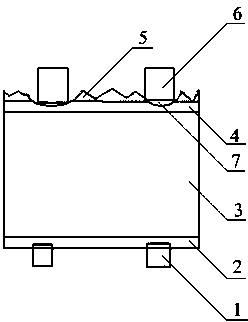

Image

Examples

preparation example Construction

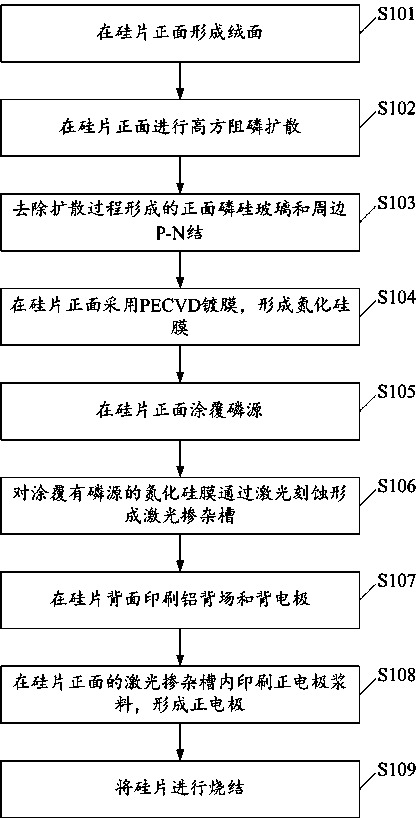

[0045] image 3 It is a flowchart of the preparation method of the high-efficiency crystalline silicon solar cell of the present invention, including:

[0046] S101, forming a textured surface on the front side of the silicon wafer.

[0047] The front side of the silicon wafer is suede, which can reduce the surface reflectivity and increase the utilization rate of light.

[0048] S102, perform high resistance phosphorus diffusion on the front side of the silicon wafer, the diffusion resistance is 100~150Ω / □.

[0049] The use of high square resistance diffusion can achieve lower doping concentration, increase the open circuit voltage and short circuit current of the battery, thereby improving the photoelectric conversion efficiency of the battery.

[0050] S103 , removing the front phosphosilicate glass (PSG) and peripheral P-N junctions formed in the diffusion process.

[0051] S104, using PECVD (Plasma Enhanced Chemical Vapor Deposition, plasma enhanced chemical vapor depo...

Embodiment 1

[0076] Form a textured surface on the front side of the silicon wafer;

[0077] Perform high-resistance phosphorus diffusion on the front side of the silicon wafer, and the diffusion resistance is 150Ω / □;

[0078] Remove the front phosphosilicate glass and surrounding P-N junctions formed during the diffusion process;

[0079] PECVD coating is used on the front side of the silicon wafer to form a silicon nitride film with a thickness of 90nm;

[0080] Coating a phosphorus source on the front side of the silicon wafer by spin coating, the phosphorus source is a phosphoric acid solution with a phosphoric acid concentration of 10%;

[0081] A laser-doped groove is formed by laser etching on the silicon nitride film coated with a phosphorus source. The width of the laser-doped groove is 80 μm, so that phosphorus is doped into the silicon in the laser-doped groove. The groove pattern is a linear positive electrode grid pattern;

[0082] Print aluminum back field and back electro...

Embodiment 2

[0086] Form a textured surface on the front side of the silicon wafer;

[0087] Perform high-resistance phosphorus diffusion on the front side of the silicon wafer, and the diffusion resistance is 100Ω / □;

[0088] Remove the front phosphosilicate glass and surrounding P-N junctions formed during the diffusion process;

[0089] PECVD coating is used on the front side of the silicon wafer to form a silicon nitride film with a thickness of 75nm;

[0090] A phosphorus source is coated on the front side of the silicon wafer by spin coating, and the phosphorus source is a phosphoric acid solution with a phosphoric acid concentration of 1%.

[0091] A laser-doped groove is formed by laser etching on the silicon nitride film coated with a phosphorus source. The width of the laser-doped groove is 40 μm, so that phosphorus is doped into the silicon in the laser-doped groove. The groove pattern is a linear positive electrode grid pattern;

[0092] Print aluminum back field and back el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com