N-type nanometer black silicon manufacturing method and solar cell manufacturing method

A solar cell, N-type technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of industrial application obstacles and high cost, and achieve the purpose of reducing corrosion depth, increasing lifespan, Effect of increasing short-circuit current and open-circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

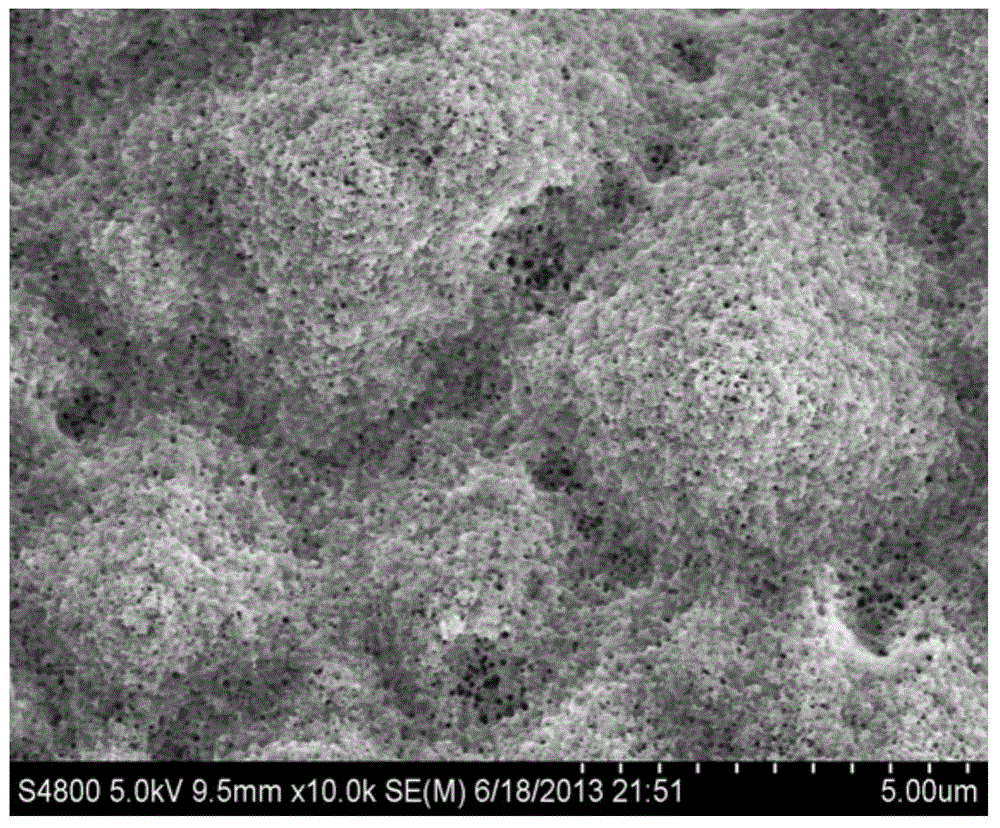

[0046] The preparation method of the N-type nano black silicon of the present embodiment comprises the steps:

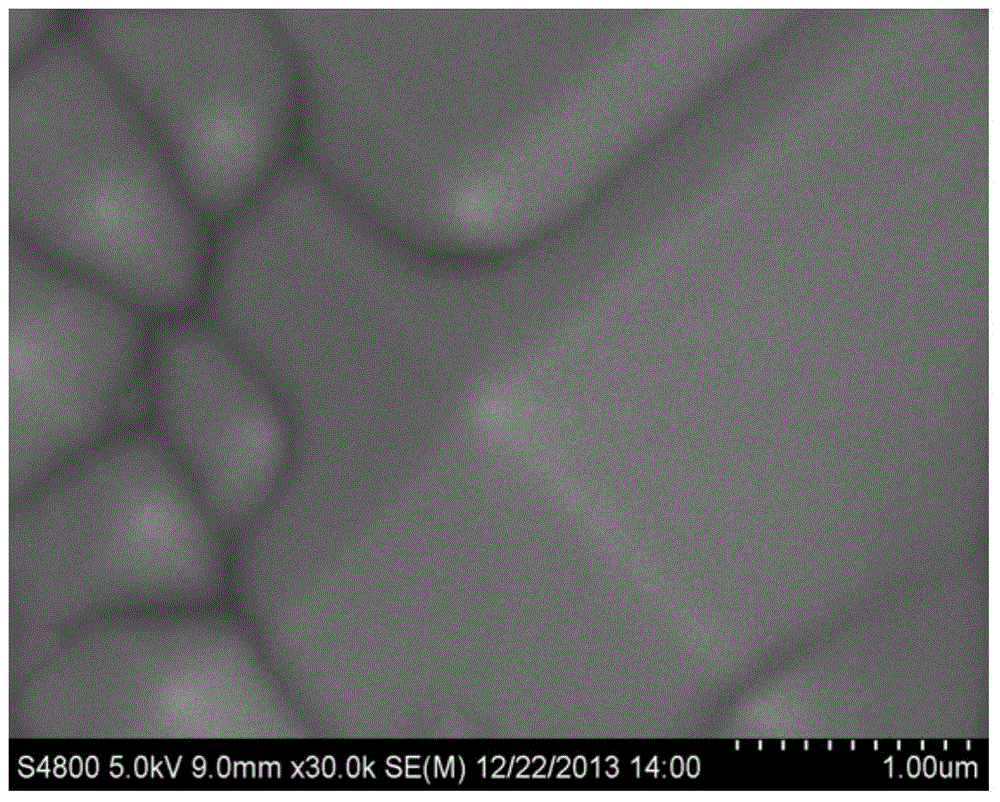

[0047] (1) 1.5g polyvinylpyrrolidone (PVP K-30) is dissolved in water, forms 50g base liquid, and the mass concentration of formaldehyde is 0.74% in the base liquid, and the mass concentration of polyvinylpyrrolidone in the base liquid is 3%, to base liquid Add dropwise silver nitrate aqueous solution mass concentration in the liquid to be 1.7%, rapidly inject ammonia water (mass fraction is 0.6ml of the solution of 28%), react 30min under 35 ℃, obtain the solution of silver nanoparticles, then add alcohol and centrifuge four times, obtain silver Nanoparticles, the silver nanoparticles are spherical, and the size (particle diameter) of the silver nanoparticles is 50nm-100nm.

[0048] (2) Put an N-type silicon wafer (N-type Czochralski single-crystal native silicon wafer) with a size of 156mm×156mm into 20mt% KOH solution, react at 80°C for 2min, and remove the damage...

Embodiment 2

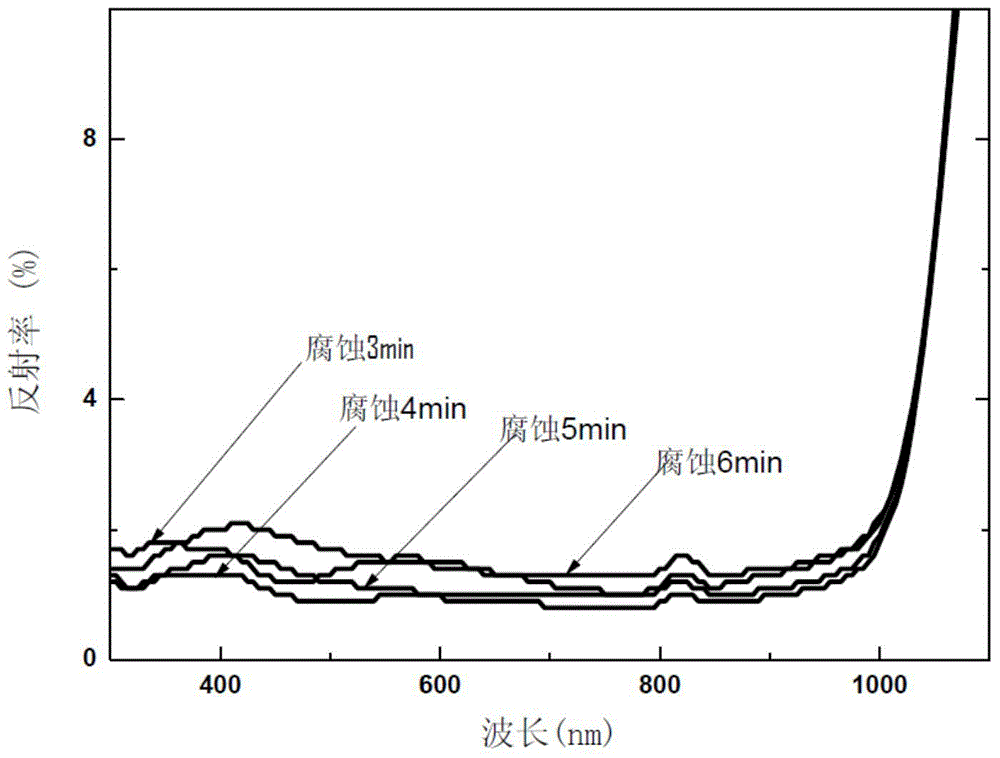

[0063] Same as Example 1, the difference is that the etching time in step (5) is 4min, and the N-type silicon wafer after step (5) is processed by the following process between step (6) and step (7) Make etch corrections:

[0064] Put the N-type silicon chip treated in step (6) into 2wt% NaOH solution and react for 3 minutes, so as to perform etching correction on the nano light-trapping structure obtained in step (5). Then put the silicon chip into 10vol% hydrochloric acid for 2 minutes to remove sodium ions, then clean the silicon chip with deionized water, and then dry it with nitrogen gas.

[0065] The nanometer black silicon N+NP solar cell prepared in Example 2 was tested for various electrical properties of the cell by using a cell efficiency sorter under the light intensity of AM 1.5, and the results are shown in Table 1.

[0066] The minority carrier lifetime of the N-type nano-black silicon prepared in this example is 5.19 μs, and the corresponding reflectivity is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

| Life expectancy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com