Boron process applicable for P+ selective emitter battery

An emitter and selective technology, applied in circuits, electrical components, climate sustainability, etc., can solve battery open circuit voltage and short circuit current limitations, high recombination of non-metallic electrode contact areas, boron selective doping and diffusion technology gaps and other problems, to achieve the effect of increasing the open circuit voltage and short circuit current, increasing the fill factor, and improving the ohmic contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

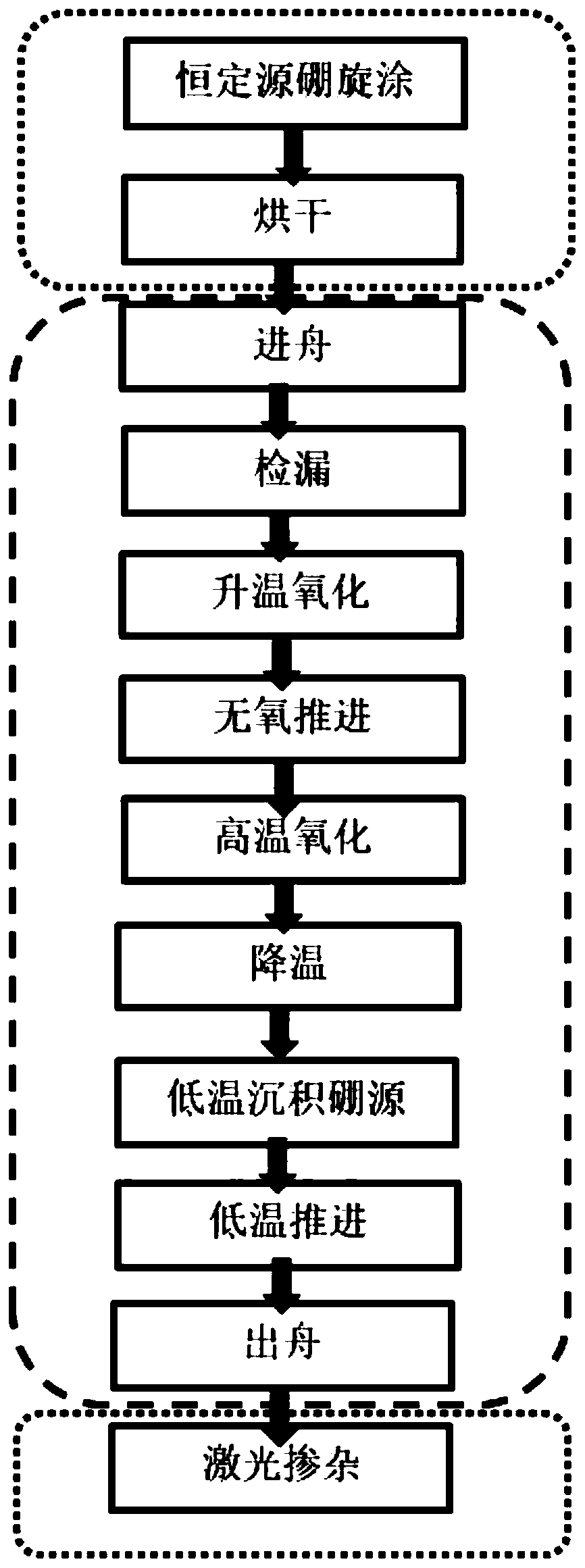

[0048] A constant source boron diffusion process suitable for P+ selective emitter batteries, the specific process is as follows: use N-type silicon wafers with high minority carrier life, resistivity 0.2-2Ω.cm, double-sided alkali washing for texture;

[0049] (1) Constant source boron spin-coating—use 1-1.5mL of immersion solution to spin on the silicon wafer, and then drop 0.4-0.8ml of boron source to spin on the silicon wafer. The spin coating method can produce a higher square resistance of 120-140 ohm, and the uniformity STD<8;

[0050] (2) Drying—on a chain machine at a temperature of 120-200°C and a drying time of 30-60s;

[0051] (3) Entering the boat - the temperature is maintained at 750-850°C, the nitrogen flow rate is 1000-2000sccm, and the time is about 8-15min;

[0052] (4) Leak detection - the flow rate of nitrogen gas is 1000-1500sccm, and the pressure is controlled at 100-200pa;

[0053] (5) Heating Oxidation—The temperature rises to 900-960°C, the nitrogen...

Embodiment 2

[0063] A constant source boron diffusion process suitable for P+ selective emitter batteries, the specific process is as follows: use N-type silicon wafers with high minority carrier life, resistivity 2-6Ω.cm, double-sided alkali-washed texture;

[0064] (1) Constant source boron spin-coating—use 1.5-2.5mL of immersion solution to spin on the silicon wafer by spin-coating, and then drop 0.3-0.6ml of boron source to spin on the silicon wafer. The spin coating method can produce a higher square resistance of 130-200 ohm, and the uniformity STD: 9-10;

[0065] (2) Drying—on a chain machine at a temperature of 180-250°C and a drying time of 40-80s;

[0066] (3) Entering the boat - the temperature is maintained at 750-850°C, the nitrogen flow rate is 1500-2500sccm, and the time is about 6-15min;

[0067] (4) Leak detection - the nitrogen flow rate is 1500-2500sccm, and the pressure is controlled at 100-200pa;

[0068] (5) Heating Oxidation—The temperature rises to 950-1000°C, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com