Method for preparing Gd-Mg intermediate alloy by fluorination system coelectrodeposition

An intermediate alloy and co-electrodeposition technology is applied in the field of preparation of Gd-Mg alloy prepared by co-electrodeposition in a fluoride molten salt electrolysis system, and can solve the problems of difficult uniformity of alloy composition, low solubility, and difficulty in determining the amount of precipitated rare earth, etc. Achieve the effect of reducing current efficiency, improving fluidity, and uniform composition

Inactive Publication Date: 2011-01-05

GANNAN NORMAL UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When rare earth metals are prepared by electrolysis of fluoride molten salt system, the solubility of rare earth metals in its electrolyte molten salt is smaller than that of chlorides, and rare earth metals and magnesium can be alloyed in a larger composition range. When the rare earth content is less than 30%, the alloy density Below the molten salt of the electrolyte, the alloy will float on the surface of the electrolyte solution to form a liquid cathode. They spread out in a plane and are easily oxidized and burned during the electrolysis process and need gas protection; Magnesium alloys with rare earth content are often mixed with molten fluoride salts and are difficult to separate; in addition, with the change of electrolysis conditions, it is difficult to determine the amount of rare earth precipitated, so the obtained alloy composition is difficult to be uniform

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

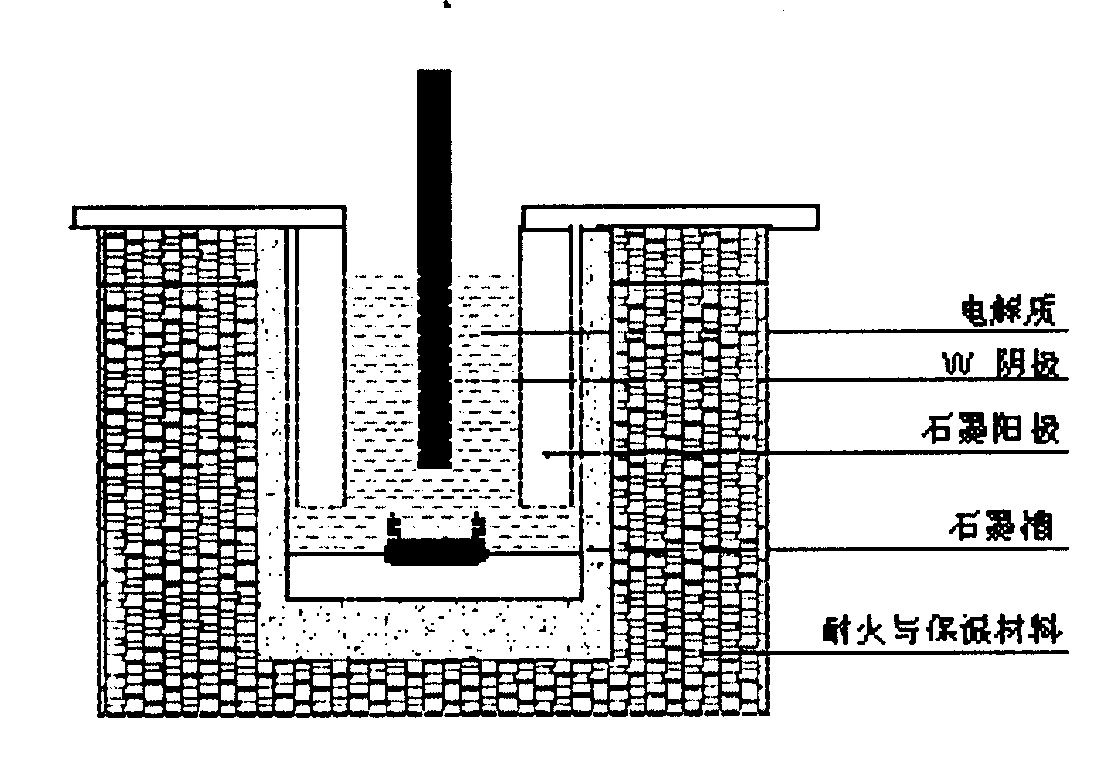

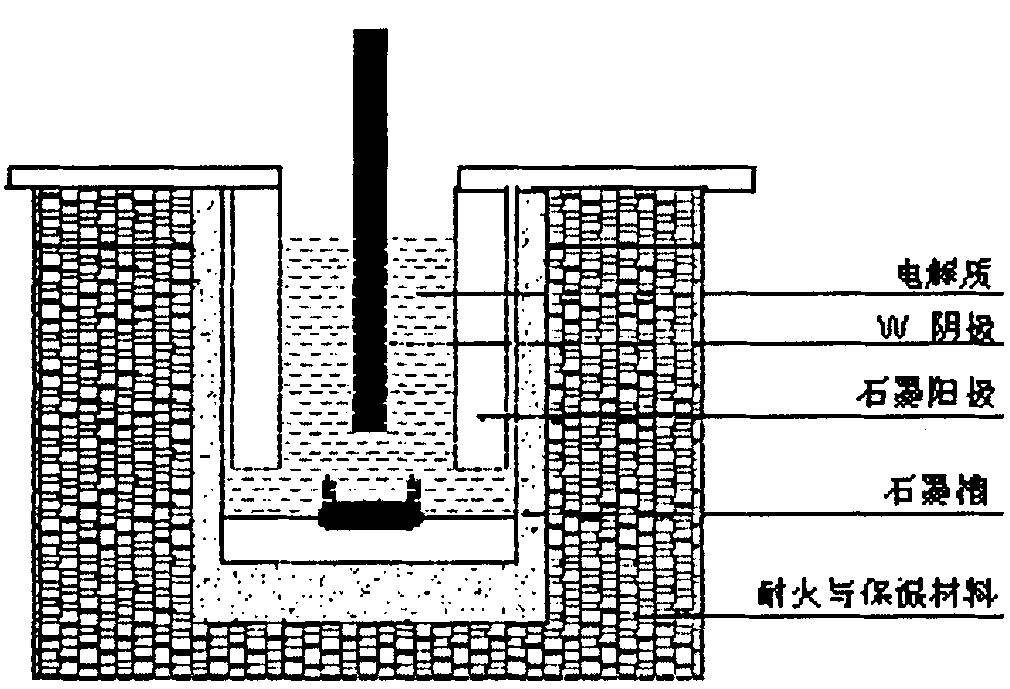

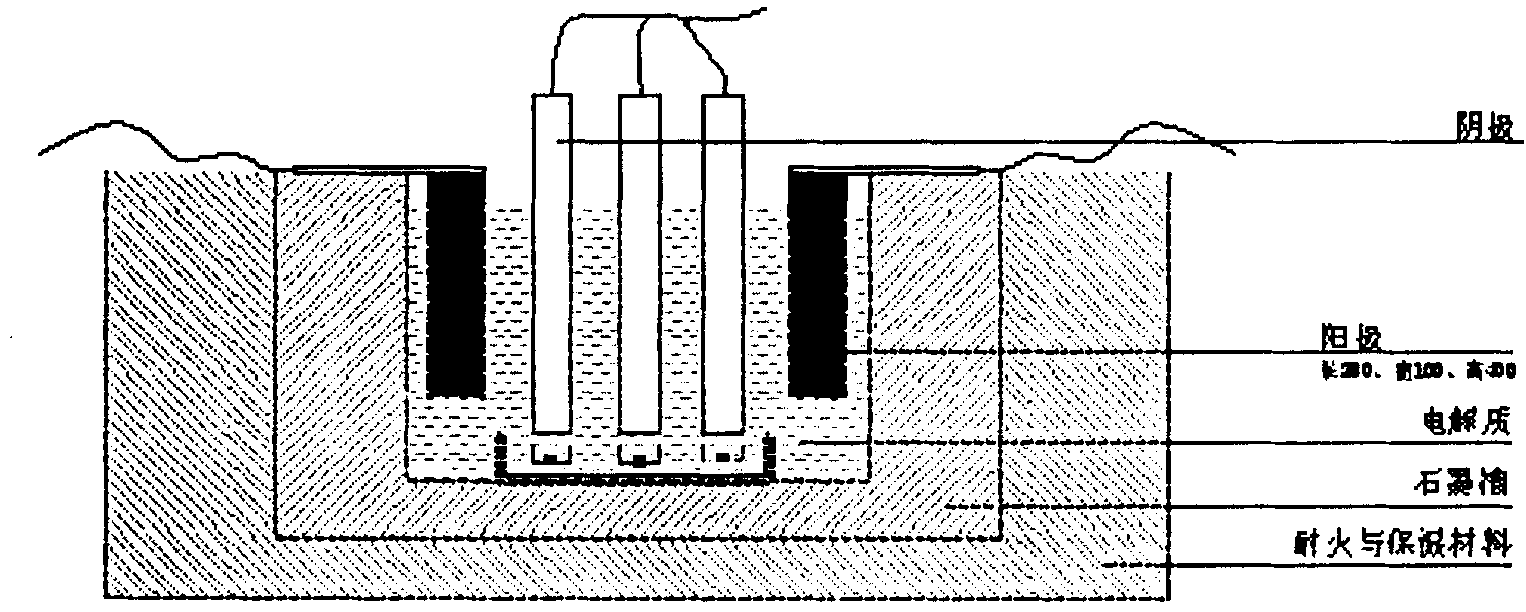

The present invention discloses a process for preparing of Gd-Mg intermediate alloy by composite electrodeposition of fluoridated systems. Gd and Mg are electrochemically separated at the cathode of a round or square electrolytic cell with the mixture of 80-95 wt% commercial Gd2O3 (purity higher than 95%) and MgO (purity higher than 95) as the raw material and GdF3-LiF or GdF3-LiF-BaF2 molten fluoride salts as the electrolytic medium and then alloyed to produce Gd-Mg intermediate alloy with the weight percentage of Gd higher than 85 percent. The prepared rear earth magnesium alloy has high magnesium content and uniform ingredients. The present invention has convenient operation that the electrolysis is continuously conducted and the tapping is conducted by the siphon method; the recovery of rear earth is higher than 90 percent, and the exhaust gas meets the requirement of environment protection; the intermediate alloy has low impurity content and low production cost.

Description

Method for preparing Gd-Mg master alloy by co-electrodeposition of fluorinated system technical field The invention relates to a method for preparing a rare earth magnesium master alloy, in particular to a method for preparing a Gd-Mg alloy by co-electrodeposition in a fluoride molten salt electrolysis system. Background technique Gadolinium-magnesium master alloy is mainly used in the preparation of high-performance heat-resistant magnesium alloys, and its service temperature can reach above 300°C. Gadolinium is one of the best elements to improve the heat-resistant properties of magnesium alloys. There are two kinds of molten salt electrolysis systems that can be used for the production of rare earth magnesium alloys by molten salt electrolysis: chloride system and fluoride system. Although some patents have been applied for chloride systems, such as Chinese Patent No. 200510119117.2, Chinese Patent No. 94113824, and Chinese Patent No. 94113824, they all use rare earth ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25C3/36

Inventor 张小联彭光怀胡珊玲邱承洲胡乔生

Owner GANNAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com