Variable focal length X-ray compound lens and manufacturing method thereof

A technology for combining lenses and a manufacturing method, applied in the optical field, can solve the problems of increased scattering, complex process, low machining accuracy, etc., and achieve the effects of high structure height and aspect ratio, low surface roughness, and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

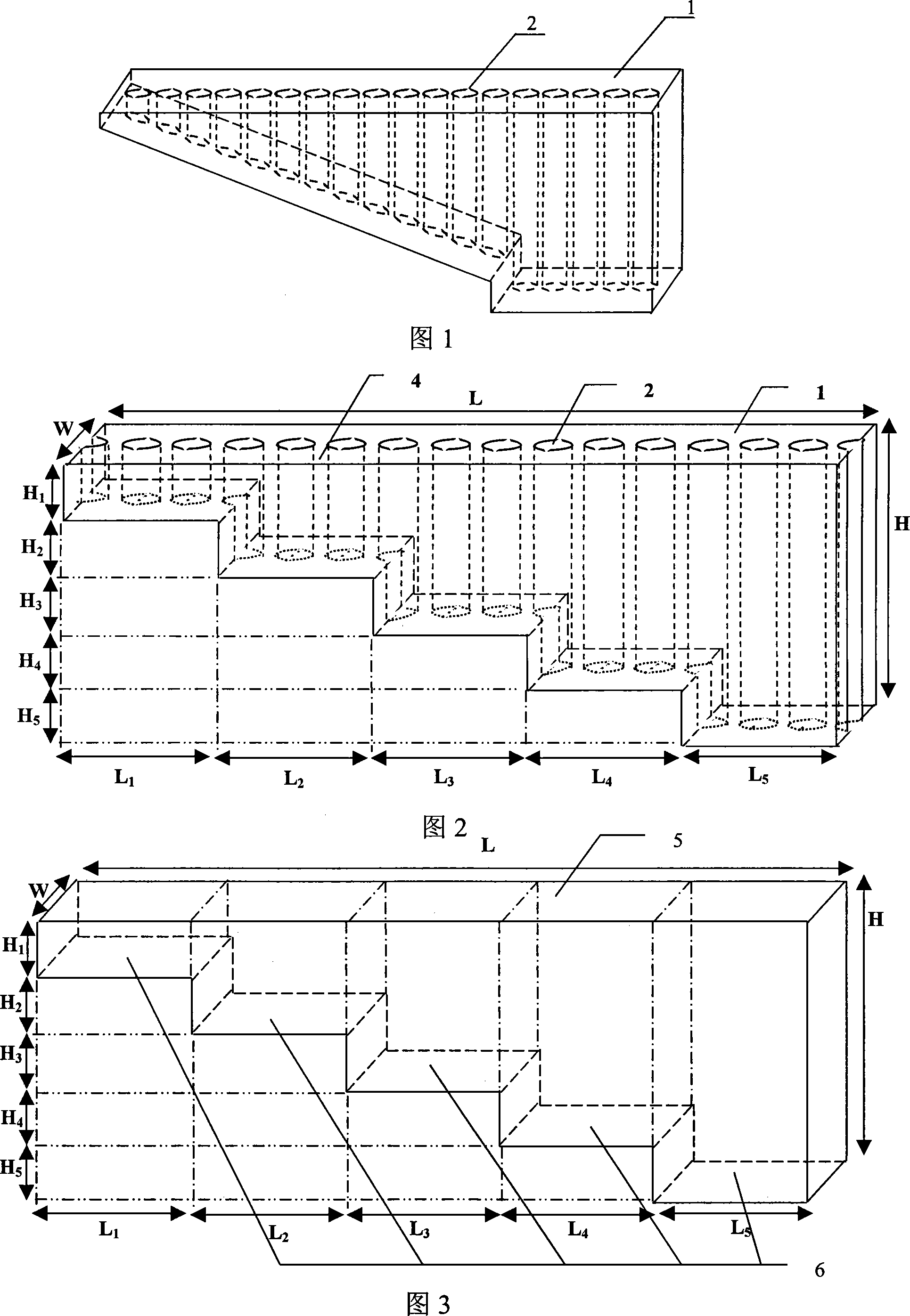

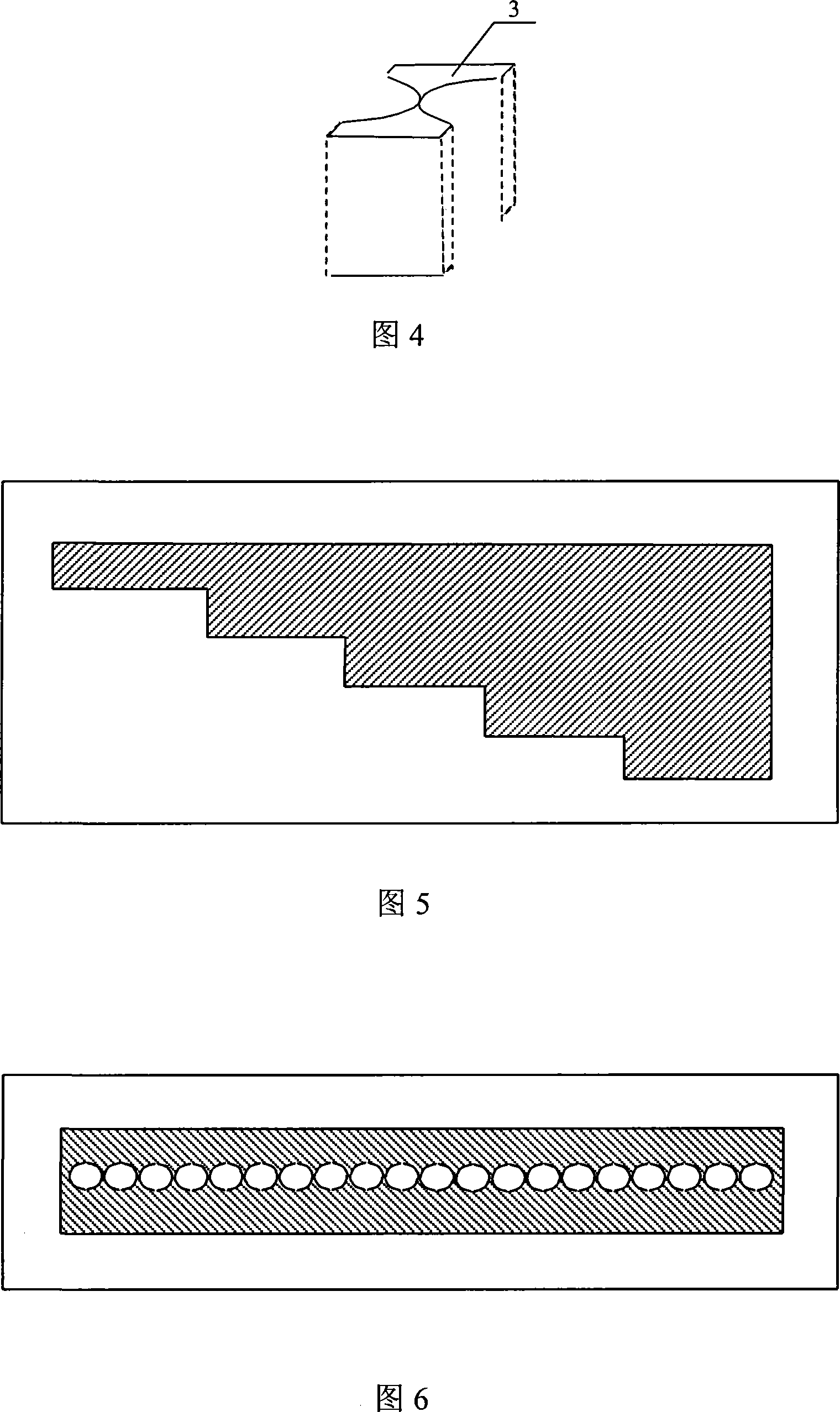

[0054] As shown in FIG. 1 , the combined X-ray zoom lens of the present invention includes a lens body 1 and air cavities 2 arranged at intervals on the lens body 1 . The gap between adjacent air cavities 2 forms a concave lens, that is, the lens unit 3 . All lens units 3 together constitute a lens group.

[0055] As shown in Figure 2, the further improved structure of the X-ray zoom combination lens of the present invention is: a row of air cavities 2 are engraved on the lens main body 1, and there is a certain gap between adjacent air cavities 2, and all the air cavities 2 are double parabolic cylinders The structure, its cross section is a figure composed of a pair of opposite parabolas, or the single parabolic cylinder structure, its cross section is a parabola, or the elliptic cylindrical structure, its cross section is an ellipse, or any other geometric shape structure that can realize focusing. In this way, the adjacent air cavities 2 together with the gaps between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com