Thulium adulterated germanate laser glass and preparation method thereof

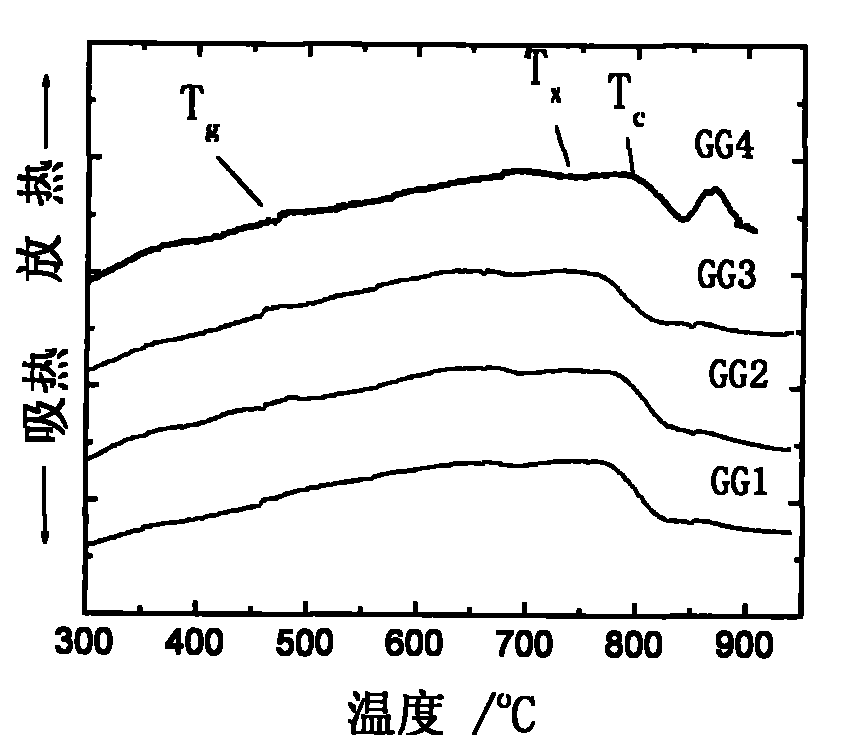

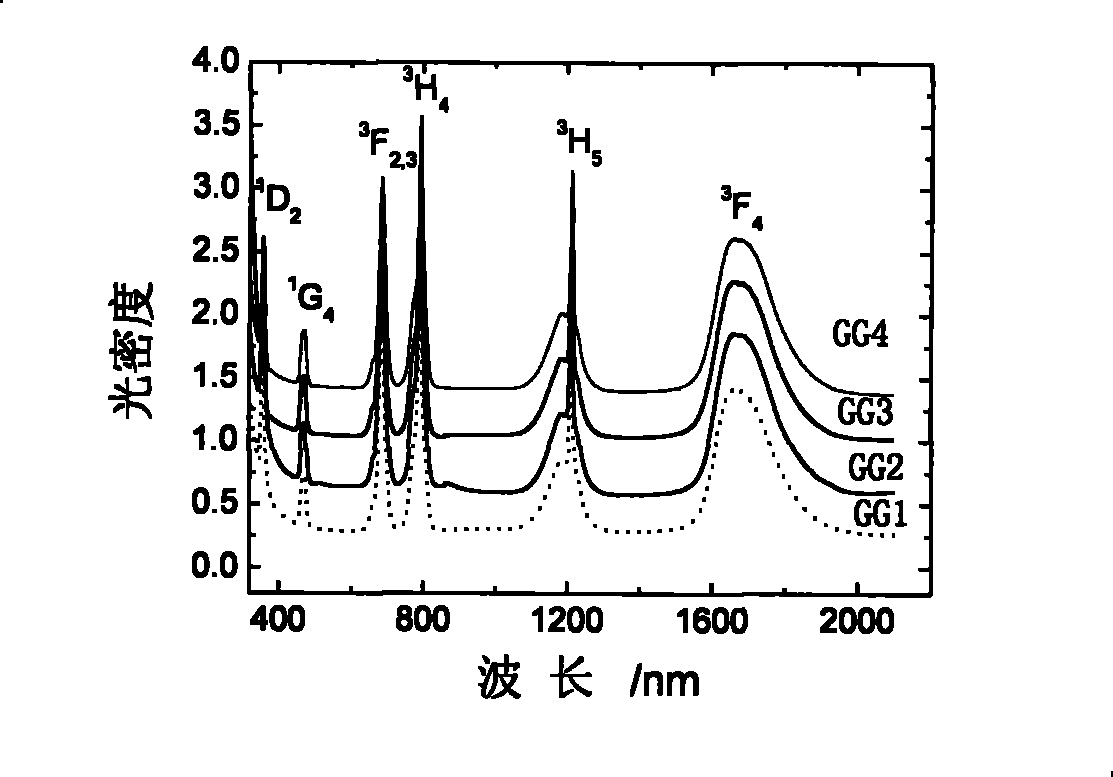

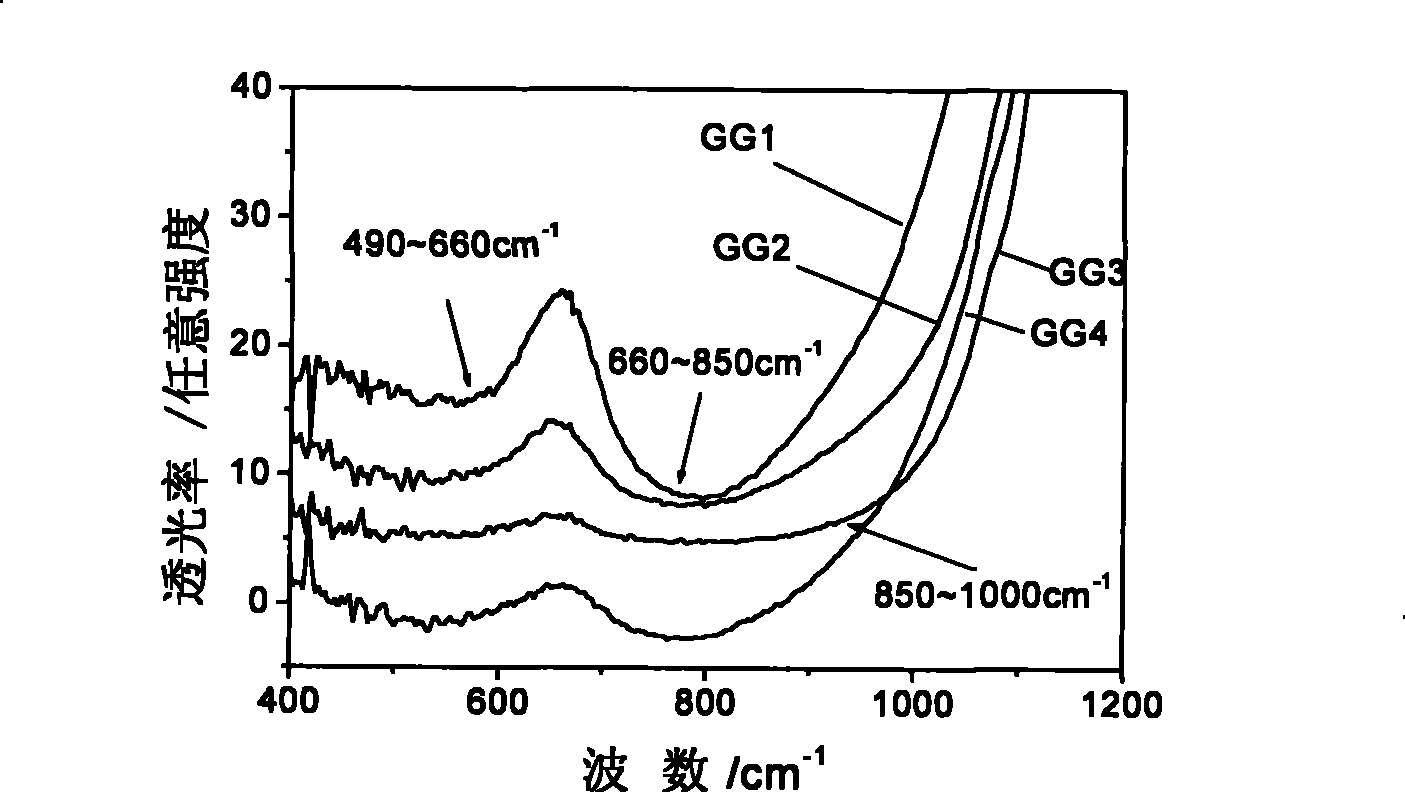

A technology of laser glass and thulium germanate, which is applied to the field of thulium doped germanate laser glass and its preparation, can solve the problems of phase separation, concentration quenching, change of physical and chemical properties of glass, etc., and achieve stable physical and chemical properties and good emission characteristics , the effect of high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of doped thulium germanate laser glass, (1) by the component of the molar percentage concentration of following chemical formula: 69mol%GeO 2 , 4mol%Ga 2 o 3 , 8mol% Li 2 O, 10mol% BaO, 5mol% La 2 o 3 , 4mol%Tm 2 o 3, respectively weigh the weight of the corresponding oxide or carbonate analysis pure raw materials, the total weight is equivalent to 50 grams of glass; after mixing the powdered raw materials evenly, put them into a platinum crucible; (2) put the platinum crucible with raw materials , placed in a silicon carbon rod high-temperature furnace preheated to about 1450 ° C for melting, and melted at this temperature for 1.5 hours, and homogenized, clarified into molten glass; (3) pour the obtained molten glass into the preheated In an iron mold with a temperature of ~250°C, about 250°C is conducive to the thermal stability of the glass, and the primary glass product is obtained; (5) quickly put the primary glass product into th...

Embodiment 2

[0033] A preparation method of thulium-germanate laser glass, which is basically the same as in Example 1, except that the molar percentage concentration is: 65mol% GeO 2 , 8mol%Ga 2 o 3 , 8mol% Li 2 O, 10mol% BaO, 5mol% La 2 o 3 , 4mol%Tm 2 o 3 .

Embodiment 3

[0035] A preparation method of thulium-germanate laser glass, which is basically the same as in Example 1, except that the molar percentage concentration is: 61mol% GeO 2 , 12mol%Ga 2 o 3 , 8mol% Li 2 O, 10mol% BaO, 5mol% La 2 o 3 , 4mol%Tm 2 o 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com