Parallel grinding and cutting method for non-axial-symmetry and non-ball-surface optical element

A non-axisymmetric, optical element technology, applied in the direction of optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of insufficient flexibility, high requirements for tools and machinery, and achieve the effect of good surface processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

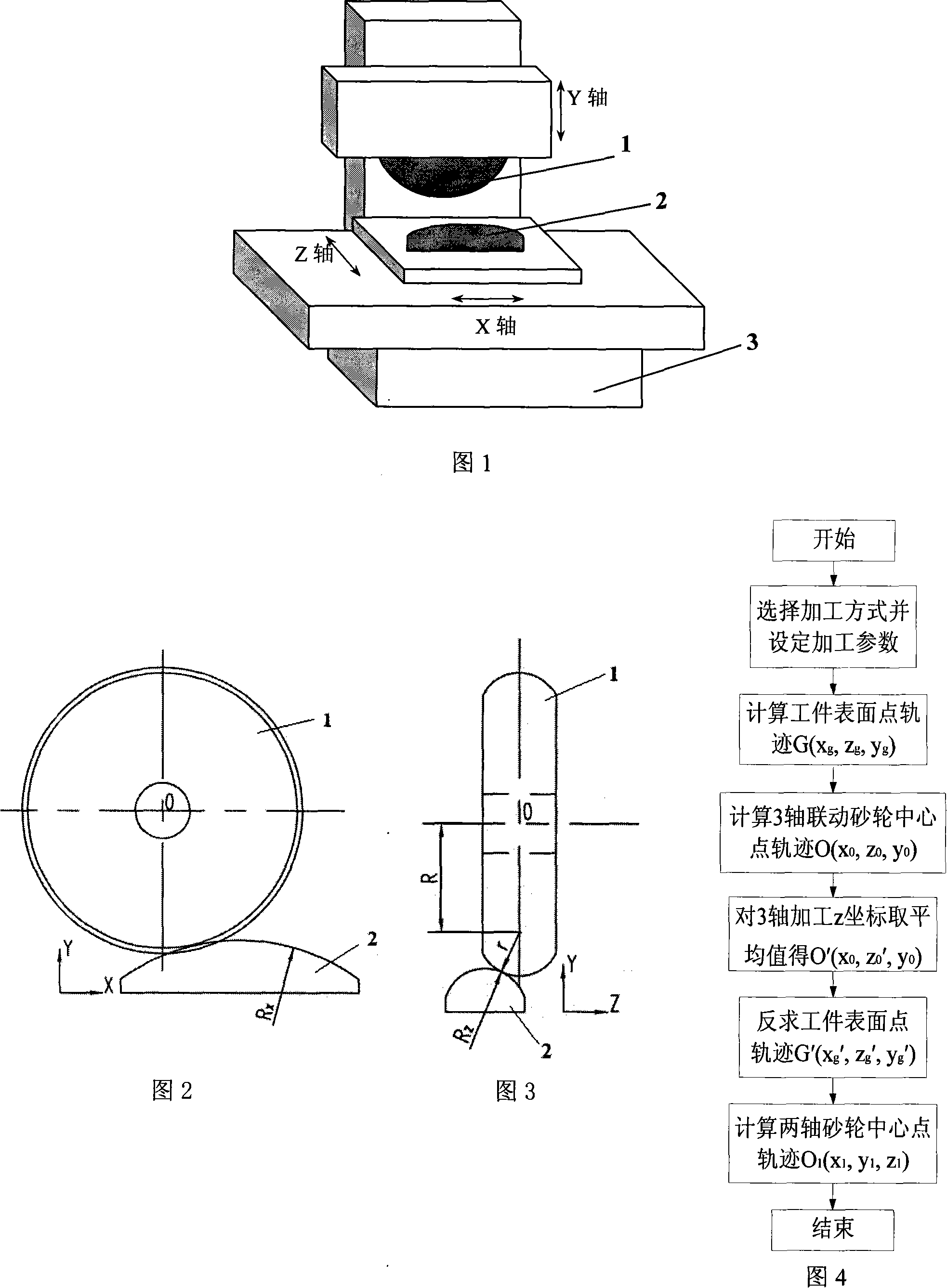

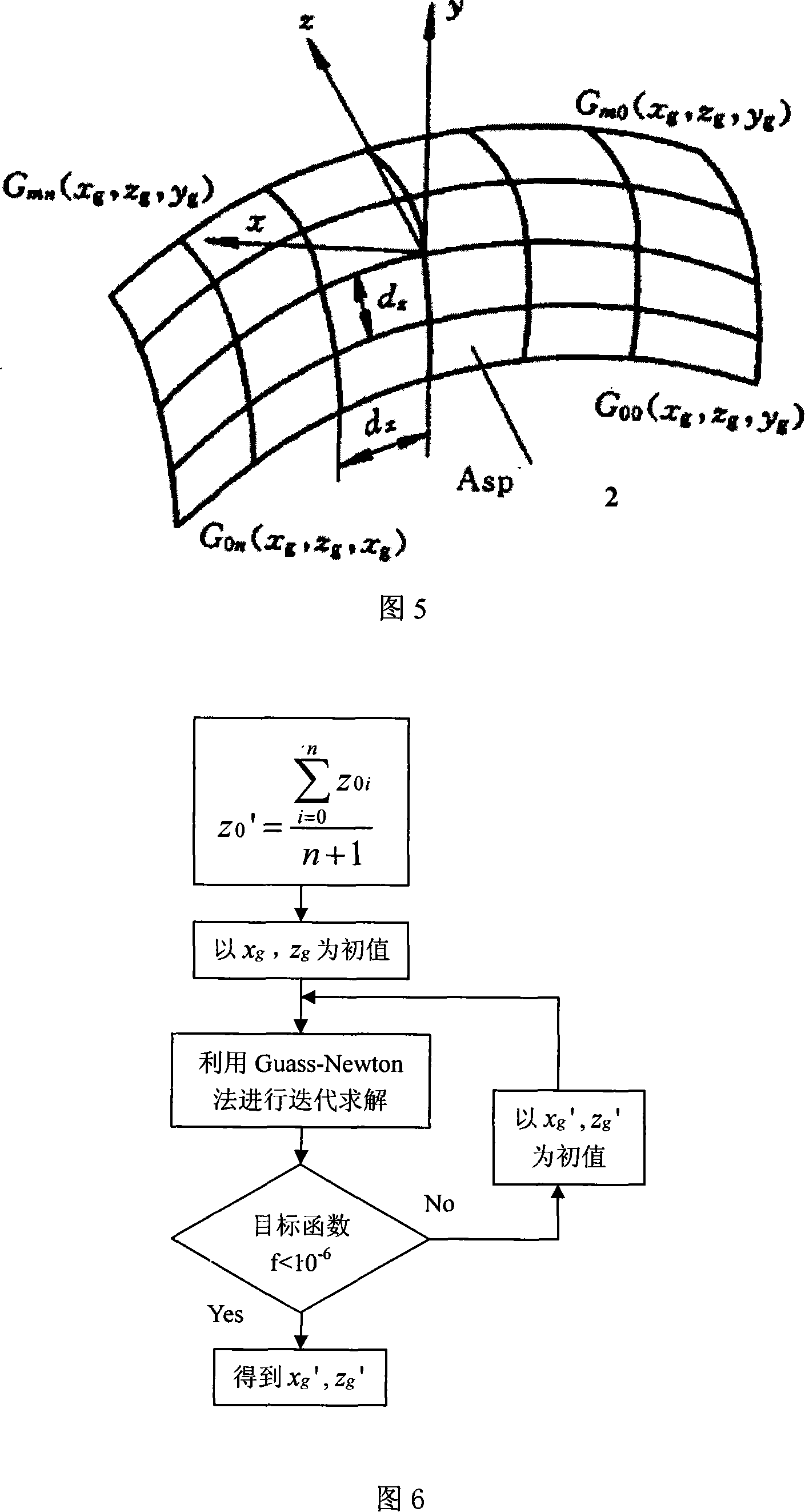

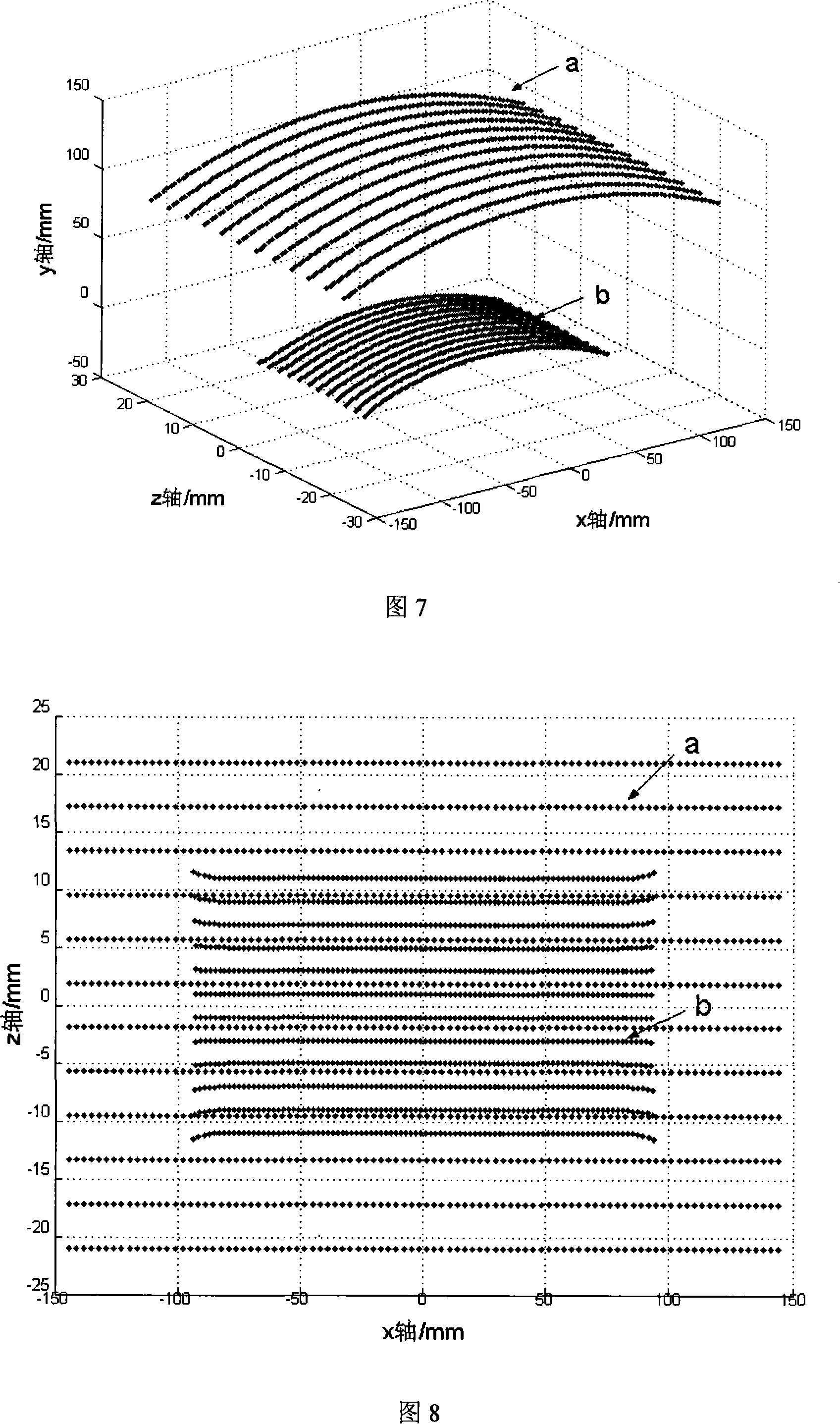

[0035] The non-axisymmetric aspheric surface processing system adopted in the present invention includes a 3-axis linkage grinding machine, an arc diamond grinding wheel, a cup-shaped grinding wheel dresser and a control computer. In order to achieve high-precision machining and simple CNC control, the x-axis linear interpolation and z-axis arc envelope processing methods are adopted, and the parallel grinding method will form parallel processing paths on the workpiece surface. During processing, the x, y, z axes are linked together to complete the surface processing of non-axisymmetric aspheric workpieces.

[0036] Fig. 1 shows the schematic diagram of the structure principle of the grinding machine used for precision surface grinding in the embodiment of the present invention, and Fig. 2 and Fig. 3 show the processing principle diagrams of the paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com