Modified producing method for trichlorosaccharose

A technology for sucralose and a production method, which is applied to the preparation of sugar derivatives, sugar derivatives, and sugar derivatives, etc., can solve the problems of high discharge of three wastes, low reaction density, unstable yield and quality, etc., and achieves a recovery rate. Increases, Reaction Steps, and Consumption Reduction Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

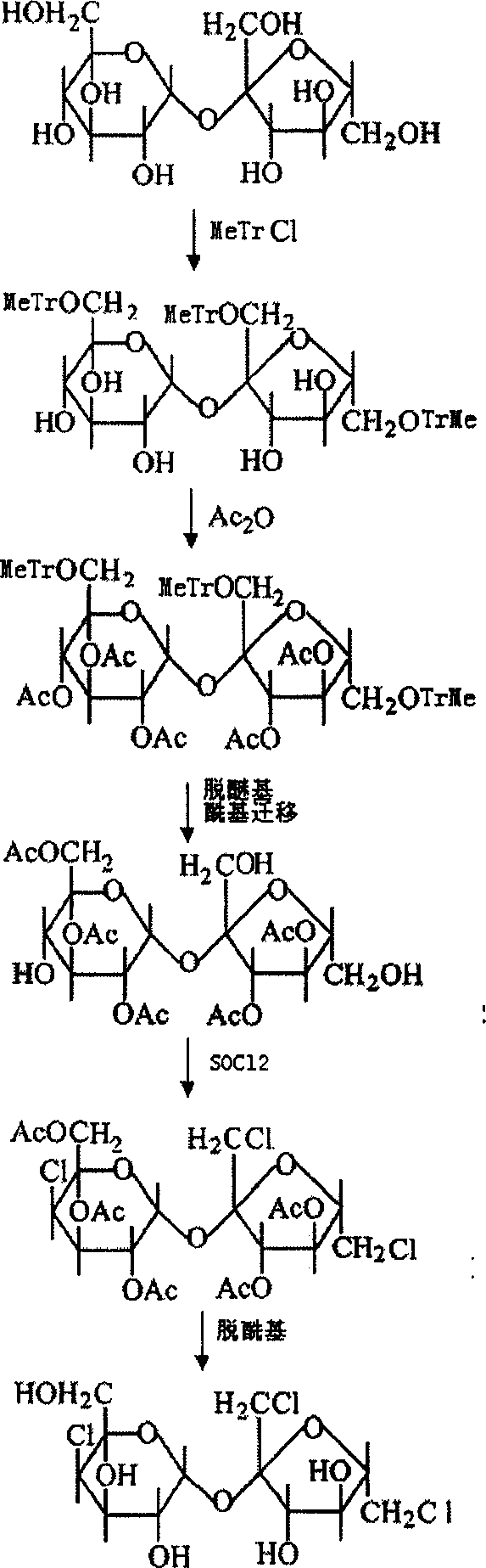

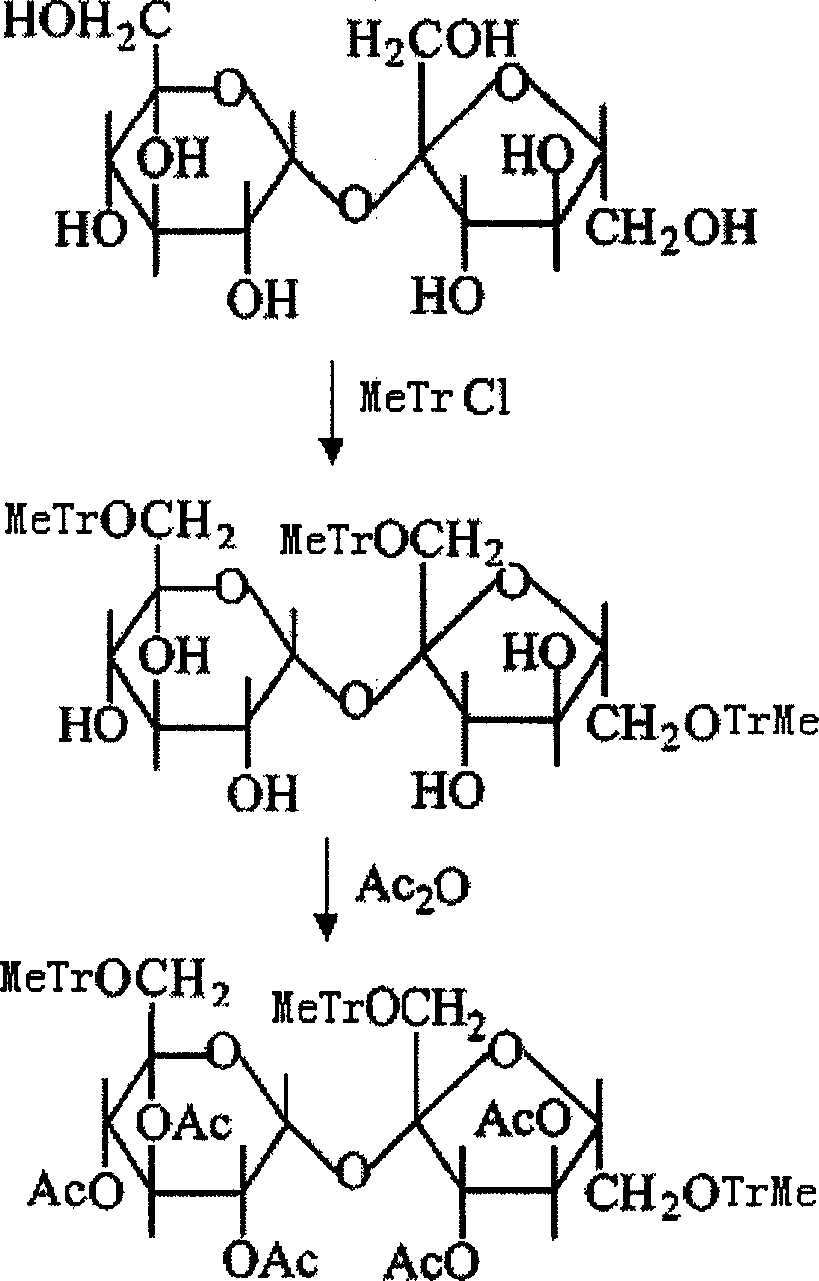

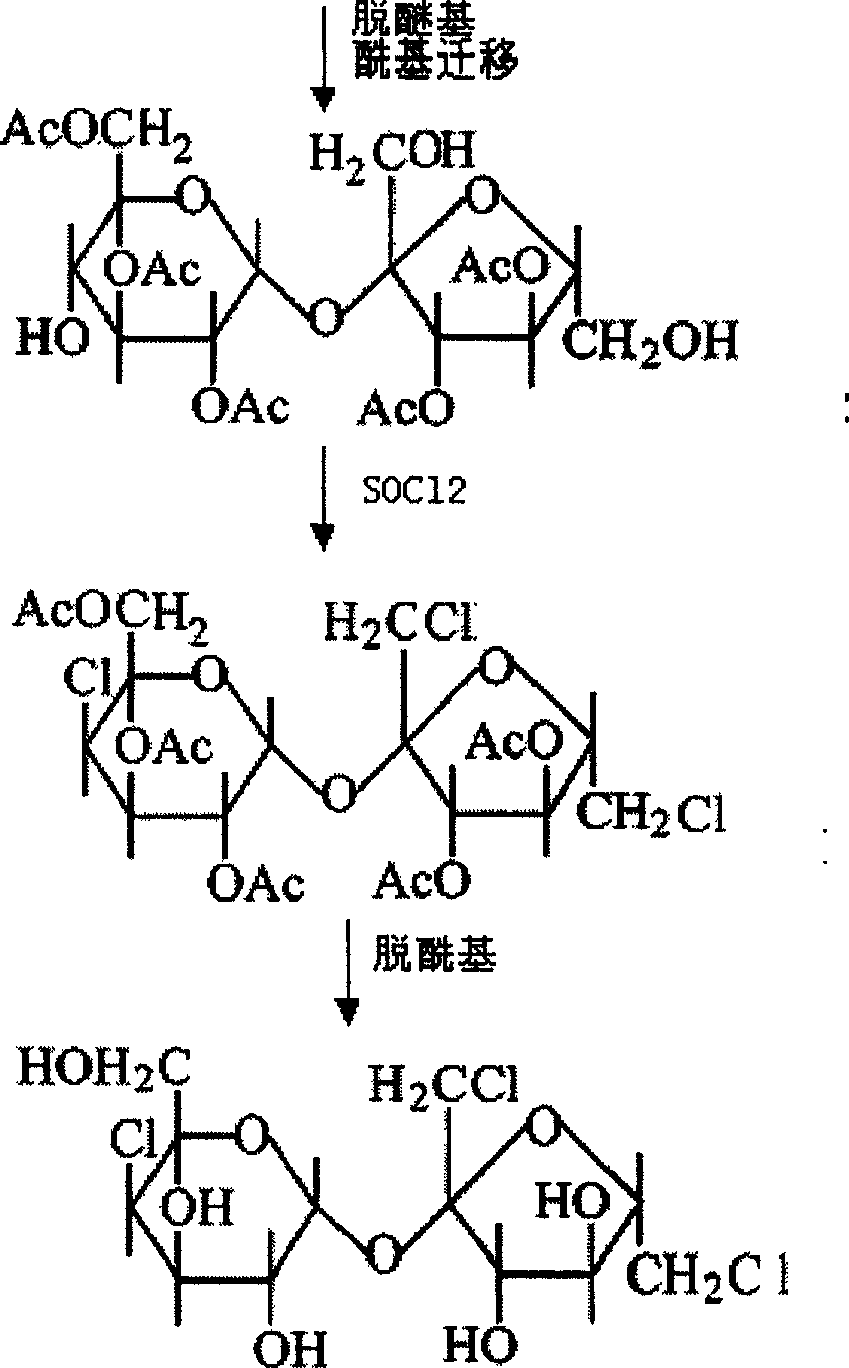

Method used

Image

Examples

no. 1 Embodiment

[0017] In the first specific embodiment of the present invention, a kind of primary hydroxyl group of sucrose is etherified with mono-p-methoxytriphenylchloromethane and acetylated. In a 1000 ml three-necked flask, 40 grams of sucrose powder (0.116mol) are added successively. and 180 milliliters of dimethylformamide, the temperature was raised to 45° C. to completely dissolve the sucrose, and 48 grams of N-methylmorpholine (0.572 mol) was added. Add 130 g of monomethoxytriphenylchloromethane (0.404 mol) within 3 hours, and react at constant temperature for 8 hours.

[0018] Add 34.4 g of sodium bicarbonate (0.41 mol) for neutralization. The reaction mixture was evaporated under vacuum to remove N-methylmorpholine, water and dimethylformamide. After the residue was dissolved in 80 ml of acetic anhydride (0.82 mol), 13 g of potassium acetate was added as a catalyst (0.132 mol) for acetylation. After cooling down slightly, the reaction mixture was poured into ice water with con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com