Method of preparing lipid nano granule

A technology of lipid nanoparticle and diffusion method, which is applied in the direction of liposome delivery and powder delivery, which can solve the problems of particle adhesion and influence on the stability of nanoparticles, and achieve the effect of high drug loading and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

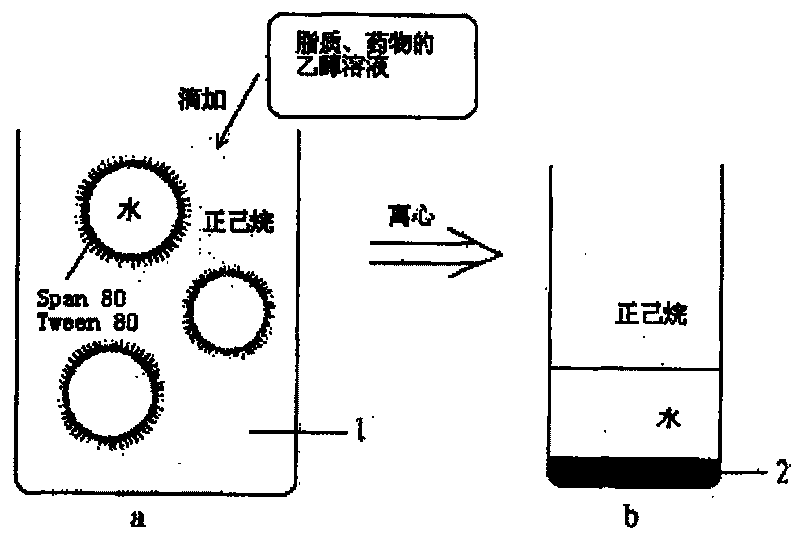

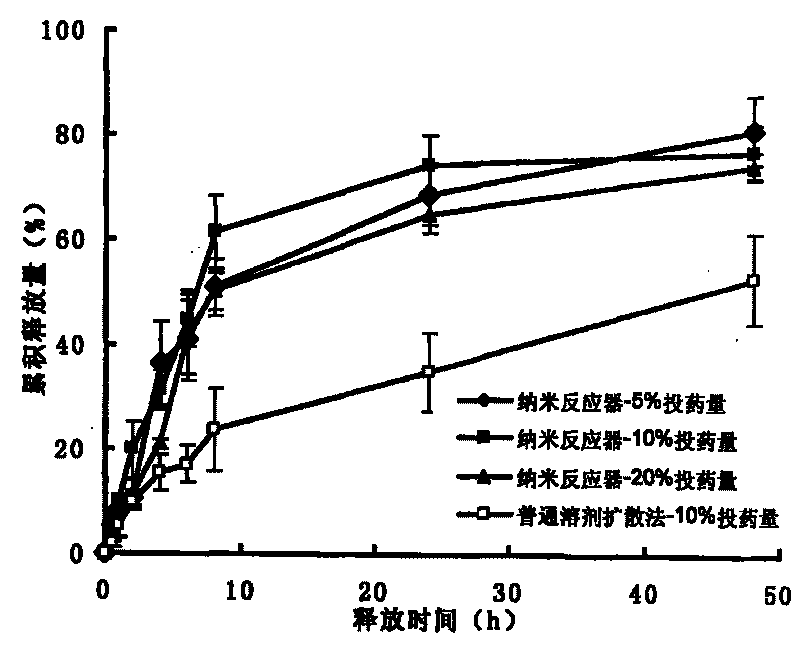

[0027] see figure 1 , the specific preparation method is as follows:

[0028] 1) Preparation of water-in-oil type submicron emulsion

[0029] The submicron emulsion consists of:

[0030] Double distilled water 14%

[0031] n-Hexane 80%

[0032] Tween 80 5%

[0033] Span 80 1%

[0034] The total weight is 8g.

[0035] Dissolve 400mg of Tween 80 in 1.12g of water to prepare the water phase, and dissolve 80mg of Span 80 in 6.4g of organic solvent to prepare the organic phase. Add the water phase to the organic phase under magnetic stirring and continue to stir for 5 minutes to pre-emulsify. The pre-emulsified emulsion is ultrasonically probed in an ice bath (condition: 400w, work for 2 seconds and stop for 3 seconds, 20 times) to form a water-in-oil submicroemulsion, that is, a nanoreactor;

[0036] The diameter of the formed submicroemulsion droplet was determined to be 75.2m.

[0037] 2) Preparation of lipid nanoparticles by solvent diffusion in submicroemulsion droplet...

Embodiment 2

[0044] 1) Preparation of water-in-oil type submicron emulsion

[0045] The preparation prescription of submicron emulsion is:

[0046] Double distilled water 5%

[0047] n-Hexane 90%

[0048] Tween 80 0%

[0049] Span 80 5%

[0050] The total weight is 8g.

[0051] The specific preparation method is as follows: 400mg Span 80 is dissolved in 7.2g organic solvent to prepare the organic phase, 0.4g pure water is added to the organic phase under the condition of magnetic stirring, and the pre-emulsification is continued for 5 minutes, and the pre-emulsified emulsion is placed on ice Probe ultrasound under bath conditions (condition: 400w, work for 2 seconds and stop for 3 seconds, 20 times) to form a water-in-oil submicroemulsion, that is, a nanoreactor;

[0052] The droplet diameter of the formed submicroemulsion was determined to be 51.6nm.

[0053] 2) Preparation of lipid nanoparticles by solvent diffusion in submicroemulsion droplets (nanoreactor)

[0054]Dissolve 47.5m...

Embodiment 3

[0059] 1) Preparation of water-in-oil type submicron emulsion

[0060] The preparation prescription of submicron emulsion is:

[0061] Double distilled water 12.5%

[0062] n-Hexane 84.75%

[0063] Tween 80 0.25%

[0064] Span 80 2.5%

[0065] The total weight is 8g.

[0066] The specific preparation method is as follows: 20mg Tween 80 was dissolved in 1g water to prepare the water phase, another 200mg Span 80 was dissolved in 6.78g organic solvent to prepare the organic phase, and the water phase was added to the organic phase under the condition of magnetic stirring, and the stirring was continued for 5 minutes Pre-emulsification, the pre-emulsified emulsion is ultrasonically probed in an ice bath (condition: 400w, work for 2 seconds and stop for 3 seconds, 20 times) to form a water-in-oil submicroemulsion, that is, a nanoreactor;

[0067] The droplet diameter of the formed submicroemulsion was determined to be 27.5nm.

[0068] 2) Preparation of lipid nanoparticles by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com