Guiding mold structure used for growth shaping single crystal alumina porcelain

A single crystal alumina, guided mode technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of unstable temperature field, high cost, difficult mass production, etc. The effect of stability, small internal stress in the crystal, and high crystallization yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

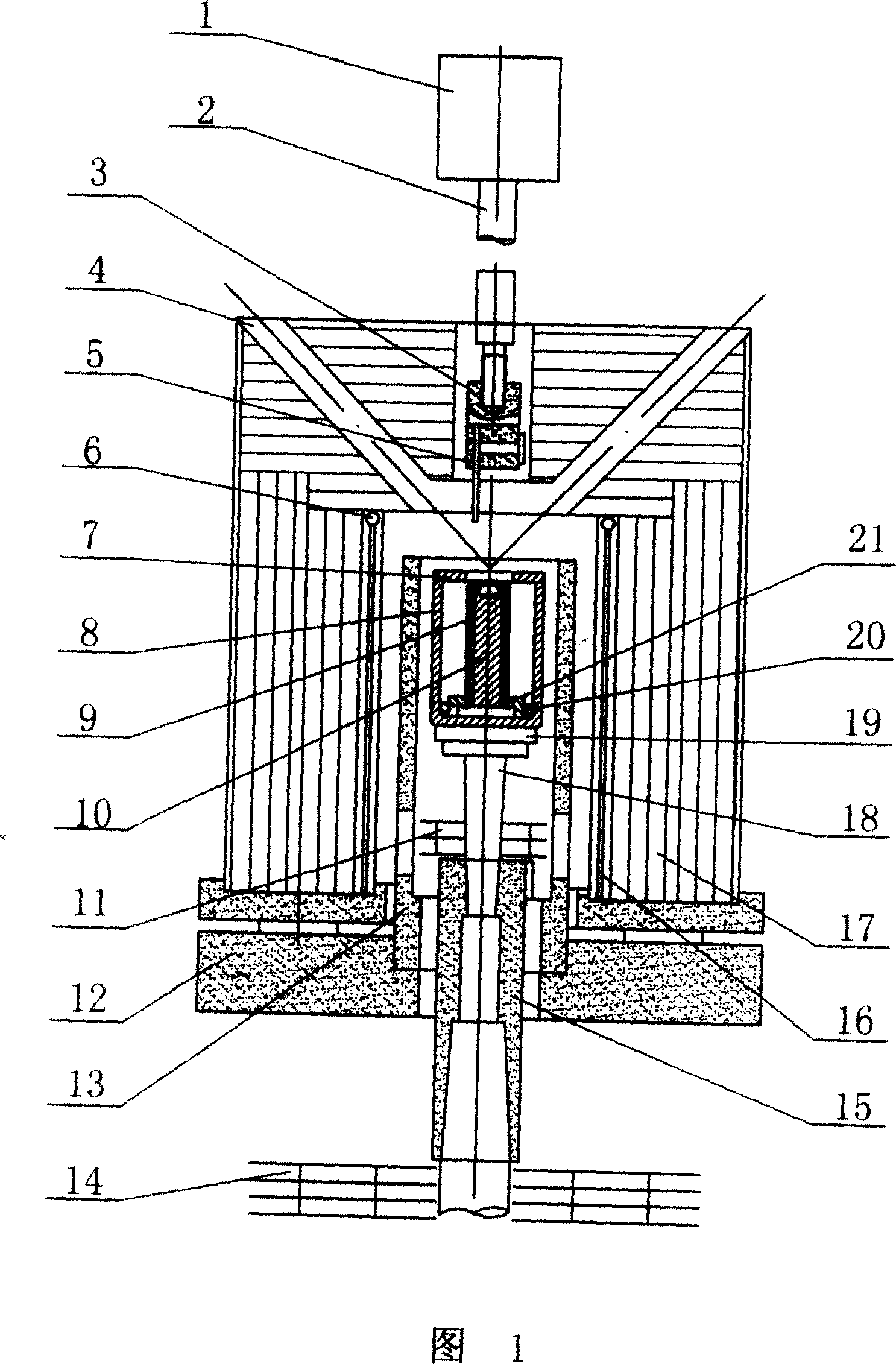

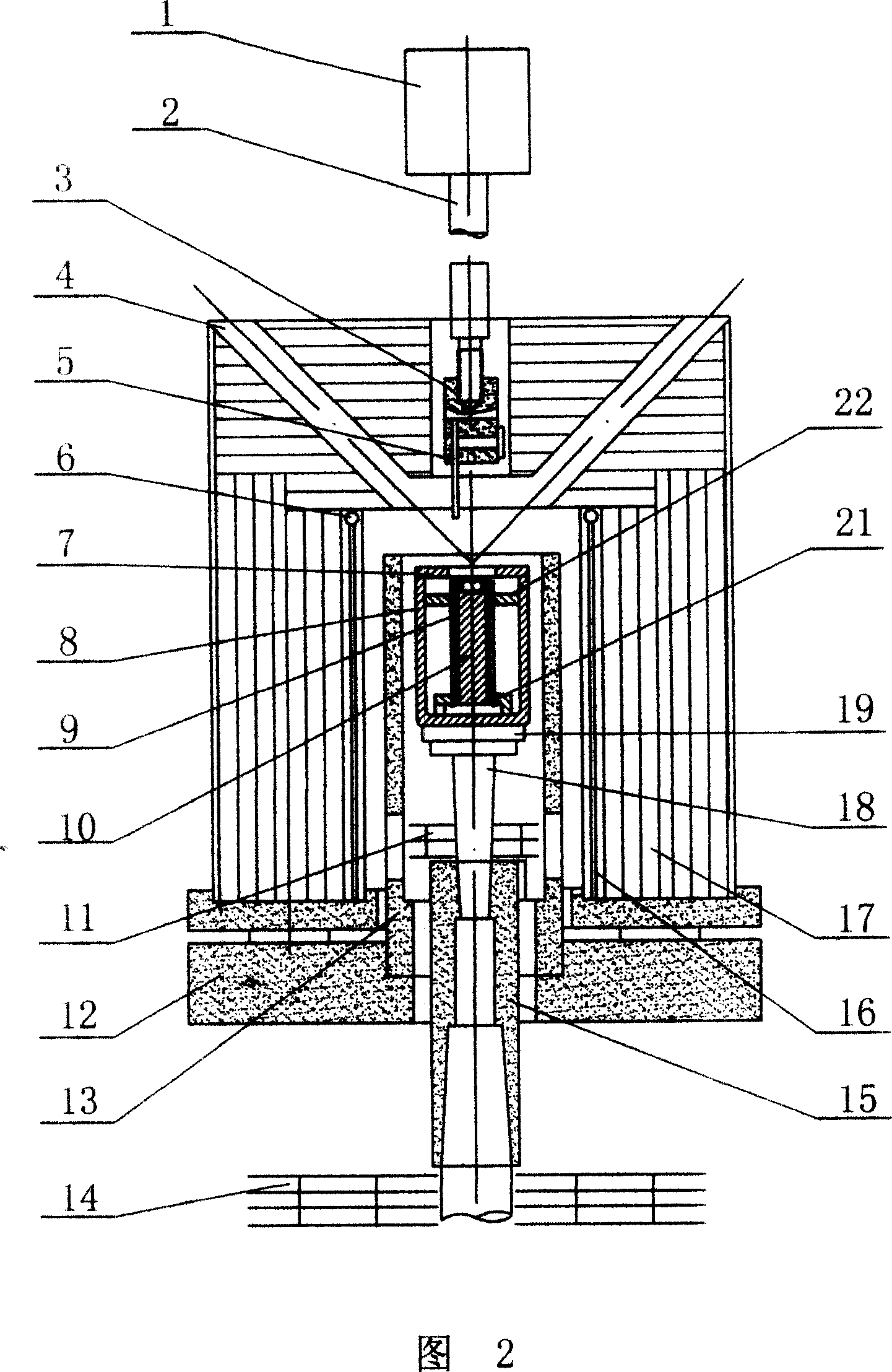

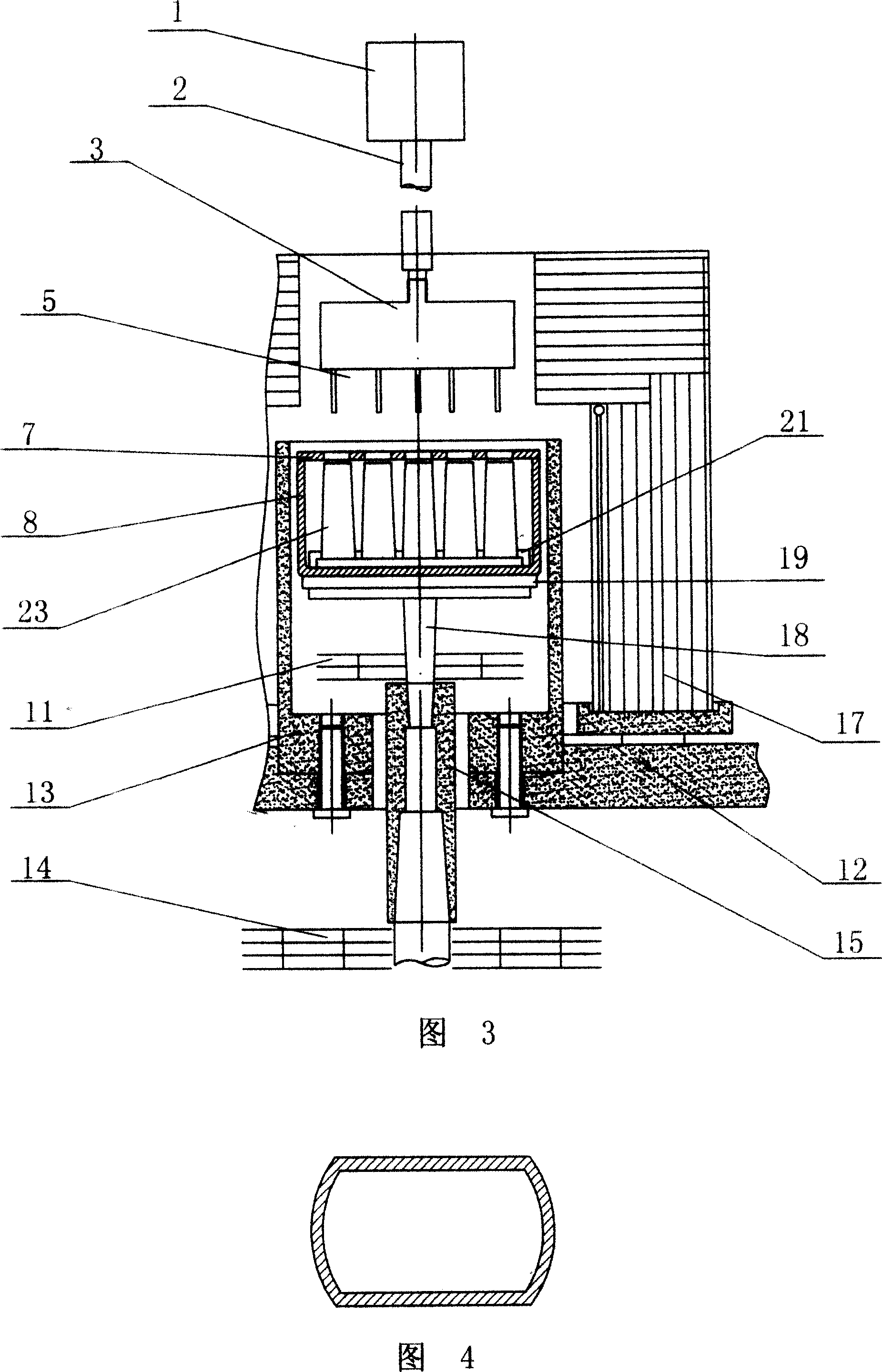

[0012] See Fig. 1, Fig. 2, the present invention comprises crucible 8, and crucible 8 is installed in heater 13 by handle 18, and heater 13 is installed in electrode plate 12, and heater 13 is provided with insulation screen 17, and insulation screen 17 is made of graphite The graphite plate of the inner layer of the thermal insulation screen 17 is a graphite plate coated with tungsten; the inner wall of the thermal insulation screen 17 can also be a molybdenum plate, and the outside of the molybdenum plate is covered with a graphite plate. The thermal insulation screens of these two structures are both The stability and uniformity of the thermal field can be guaranteed. The crystallizers provided in the crucible 8 can be provided with corresponding crystallizers according to different products. The crystallizers used to grow single crystal alumina ceramic tubes are shown in Fig. 2, and the number can be determined according to The size of the crucible is set (there are 5 in Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com