Method for producing validamycin by circulating fermentation

A technology of Jinggangmycin and its production method, which is applied in the field of circular fermentation to produce Jinggangmycin, can solve problems such as environmental pollution, and achieve the effects of reducing production costs and eliminating emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation of embodiment 1 seed and fermentation culture

[0051] 1. Seed Preparation

[0052] 1.1 Strain: Streptomyces jinggang NFY-1022 strain

[0053] 1.2 Medium

[0054] 1.1.1. Slant medium (mother slant and eggplant bottle slant, each content percentage in the medium is weight percentage, the same below)

[0055] Glucose 1.0% Asparagine 0.05% KH 2 PO 4 0.05%

[0056] Agar 1.6% pH Natural

[0057] 1.1.2 Seed medium

[0058] Rice flour 4.0% Peanut meal powder 1.0% Yeast powder 0.5%

[0059] Soybean Meal Powder 1.0% Peptone Powder 0.5% KH 2 PO 4 0.025%

[0060] CaCO 3 0.3% NaCl 0.2% pH Natural

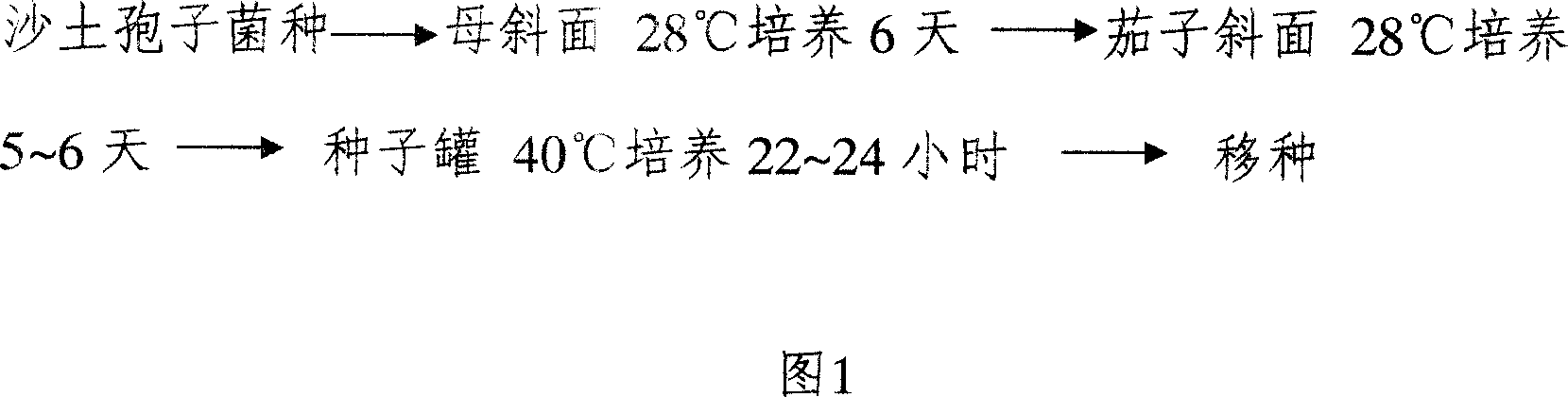

[0061] 1.3 The seed preparation process is shown in Figure 1:

[0062] 1.4 Preparation of slant medium

[0063] 1.4.1 Weighing and calculation: first calculate according to the proportional requirements, and then weigh them separately. The water used for preparing slopes should be distilled water or synthetic water, and agar powder or good agar strips shou...

Embodiment 2

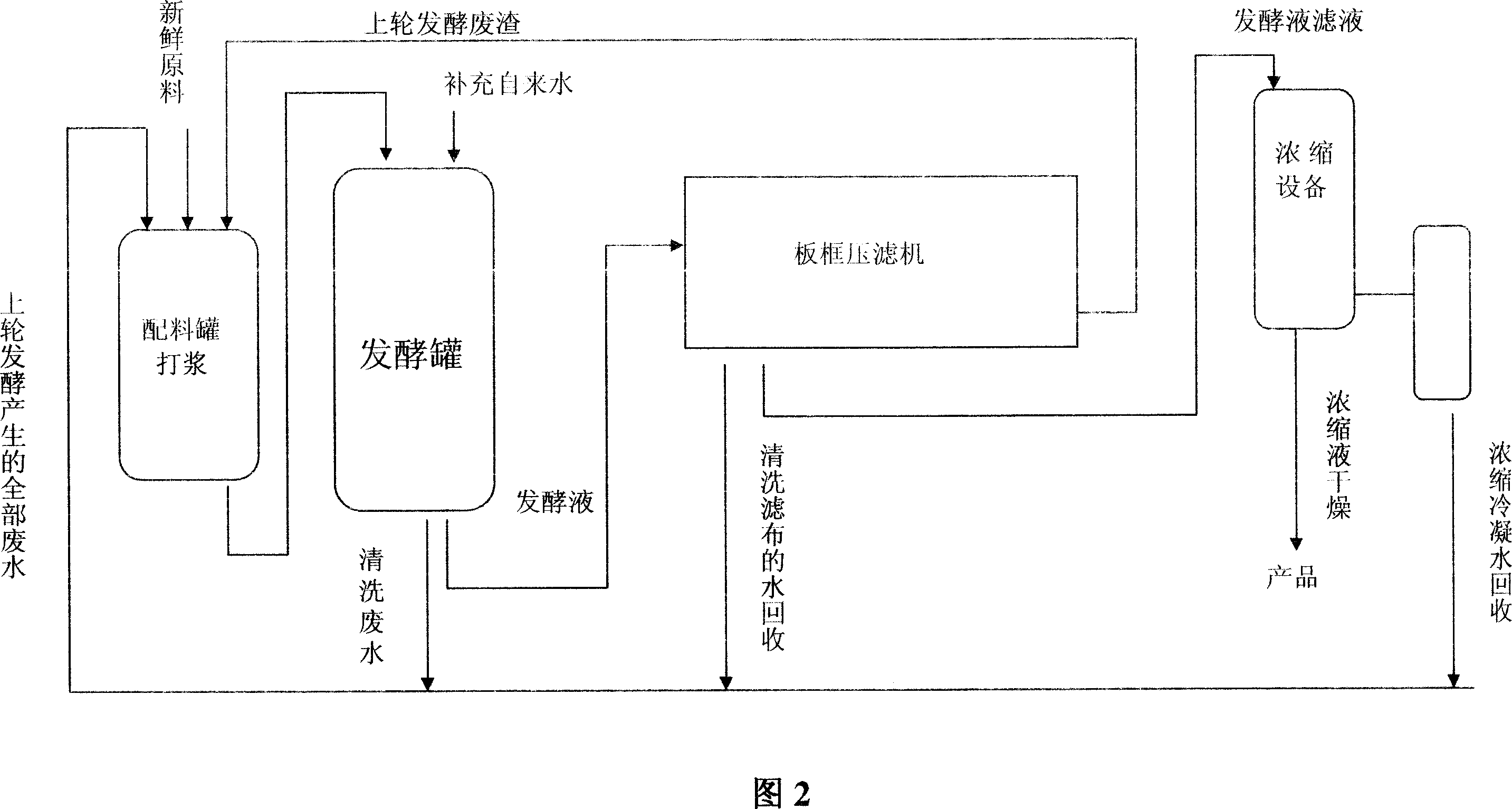

[0166] Example 2 Jinggangmycin Circulating Fermentation Medium

[0167] Formula 1: 9% rice flour, 11% Jinggangmycin wet fungus residue (moisture content 75%), 0.15% soybean cake powder, 0.7% yeast powder; 3% calcium carbonate, pH7.2 (before disinfection).

[0168] Formula 2: 10% rice flour, 12% Jinggangmycin wet fungus residue (moisture content 76%), 0.15% soybean cake powder, yeast powder (0.7%, calcium carbonate 4%, pH 7.2 (before disinfection).

[0169] Formula 3: 9.5% rice flour, 13% Jinggangmycin wet fungus residue (moisture content 75%), 0.15% soybean cake powder, 0.7% yeast powder, 3% calcium carbonate, pH7.2 (before disinfection).

[0170] Formula 4: 10% rice flour, 14% Jinggangmycin wet fungus residue (moisture content 76%), 0.15% soybean cake powder, 0.7% yeast powder, 3% calcium carbonate, pH7.2 (before disinfection).

[0171] Formula 5: 5% corn starch, 30% Jinggangmycin wet fungus residue (moisture content 50%), 0.1% soybean cake powder, 5% peanut cake powder, 0.5...

Embodiment 3

[0174] Embodiment 3 60 liters fermenter fermentation

[0175] 1.1 Seed culture medium (each percentage in the culture medium is weight percentage, the same below) rice flour 5.0% peanut meal powder 0.5% yeast powder 0.5% KH 2 PO 4 0.025% CaCO 3 0.3% NaCl 0.2% PH natural

[0176] 1.2 Original fermentation medium (CK)

[0177] Rice flour 10% Soybean meal 2.5% Yeast powder 0.5%

[0178] K H 2 PO 4 0.30% CaCO 3 0.1% NaCl 0.15% pH7.0

[0179] 1.3 Using Example 2 Formula 1 as Jinggangmycin Wet Slag Fermentation Medium

[0180] 1.4 Process control

[0181] 1.4.1 After inoculation of the seed tank, the fermentation temperature is 40°C, and the stirring speed is 200rpm.

[0182] 1.4.2 The fermentation period of the fermenter is 41 hours, the inoculation amount is 5%, the fermentation temperature is 40°C, the tank pressure is 0.05Mpa, the ventilation rate: 0-8 hours 1: 1.2v / v / min; 8-41 hours 1: 1.5v / v / min, stirring speed 250rpm.

[0183] 1.4.3 The fungus residue filtere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com