Apparatus for pretreating composite material metal base material and pretreating method

A pretreatment device and technology for metal substrates, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of destroying the mechanical properties of the substrate, uneven internal stress of the substrate, affecting product quality, etc., to ensure lubricity. And the effect of long-term use, reduction of uneven heating, and reasonable heating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The metal base material in this embodiment is a steel base belt, and the material of the outer layer corresponding to the composite procedure is EAA plastic resin 30707, and the melting point of the plastic is 102°C.

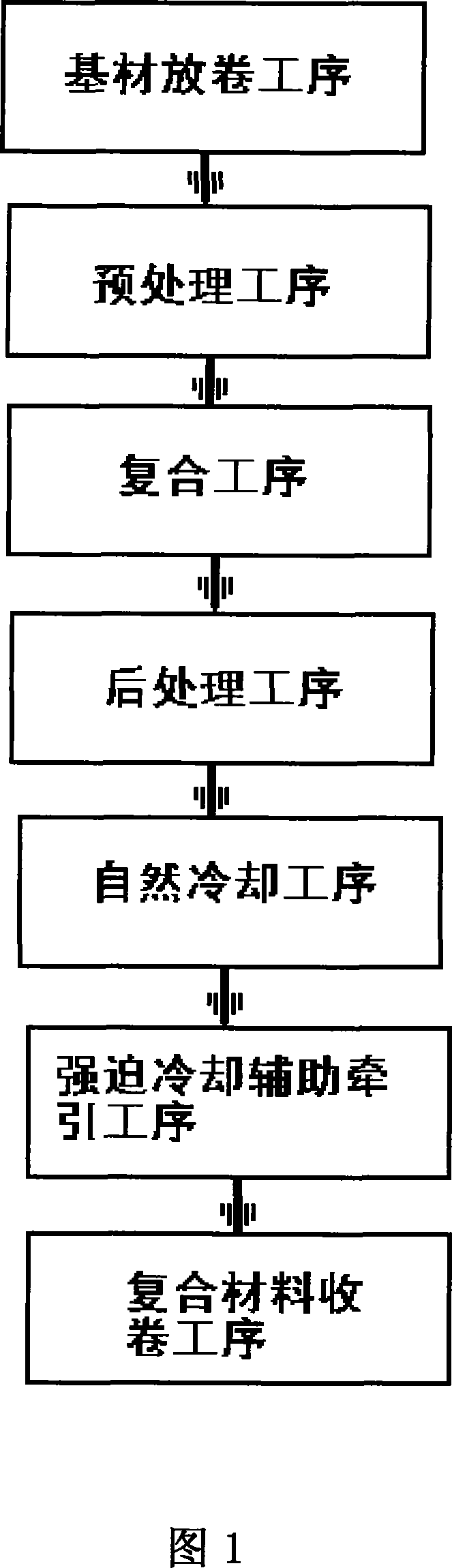

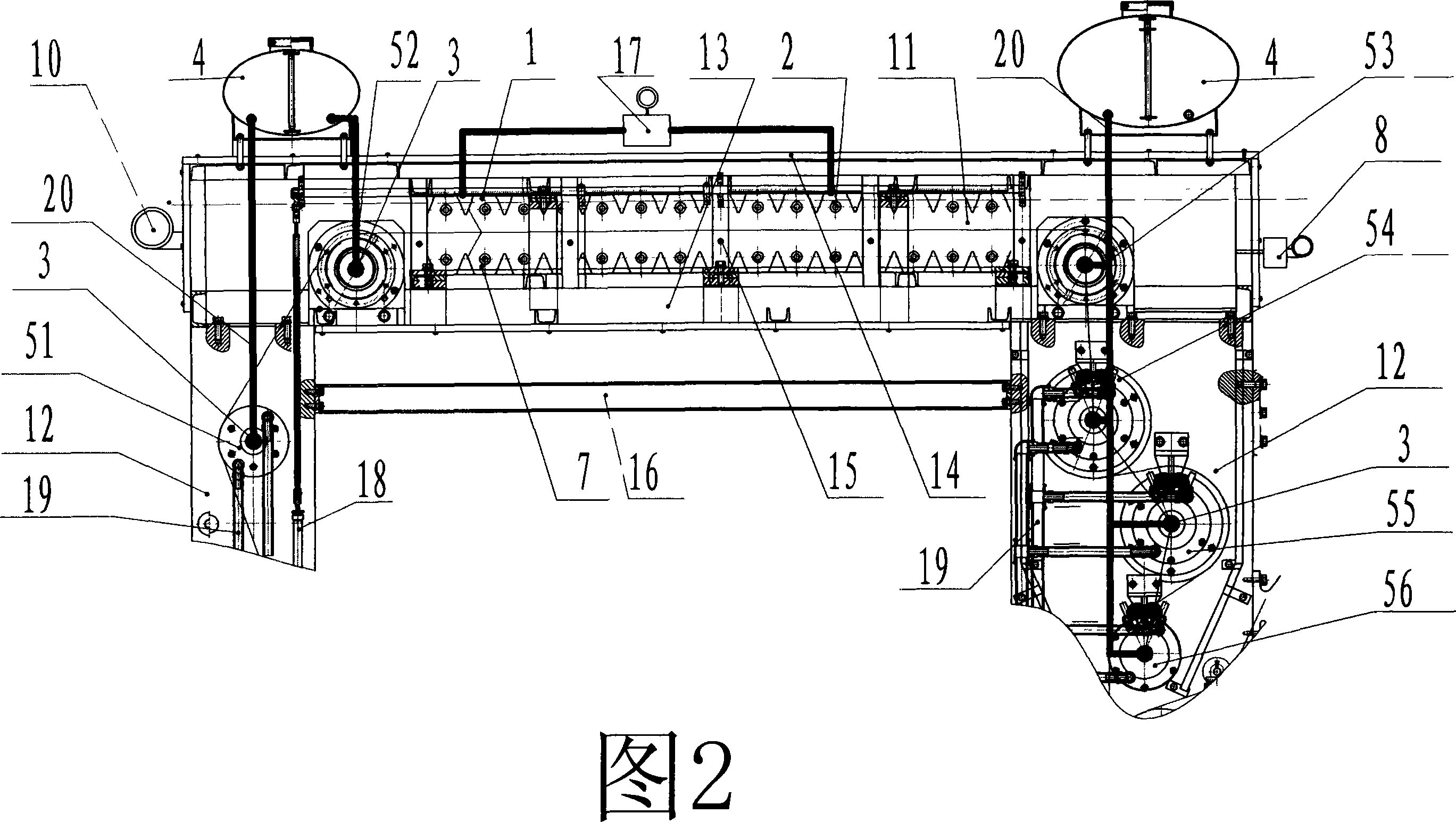

[0065] ① Firstly, the steel base strip conveyed in the unwinding program respectively bypasses the first heating guide roller 51, the second heating guide roller 52, passes through the box body 13, bypasses the third heating guide roller 53, the fourth heating guide roller 54, The fifth heating guide roll 55 and the sixth heating guide roll 56, then the steel base strip of the composite material is transported to the following composite program at a linear speed of 40m / min;

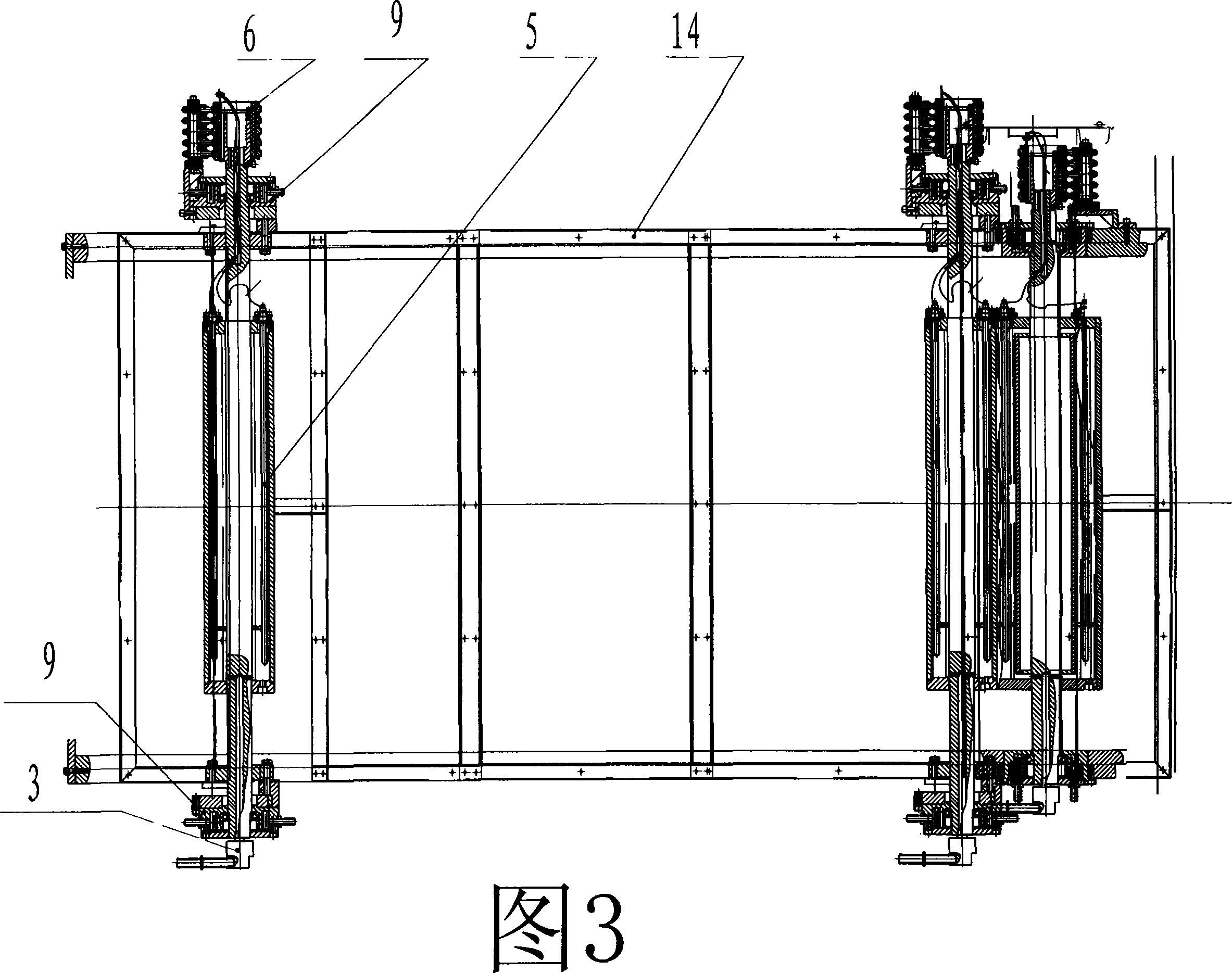

[0066] ② Turn on the pretreatment device for the metal base material of the composite material, the upper heating device 1 and the lower heating device 7 in the box body 13 are heated to 150-550°C, and the collector ring 6 connected to the power supply is energized to each heating gui...

Embodiment 2

[0071] The metal base material in this embodiment is copper base tape, and the material of the outer layer corresponding to the composite procedure is EAA plastic resin 30707, the melting point of which is 102°C.

[0072] The operating process of this embodiment is the same as that of Example 1, and the operating parameters are: the linear velocity is 30-50 m / min, the temperature inside the box is 100-450°C, the oil temperature of the heating guide roller is 100-350°C, and the surface temperature of the heating guide roller is 80-450°C. 320°C.

Embodiment 3

[0074]The metal base material in this embodiment is aluminum base tape, and the material of the outer layer corresponding to the composite procedure is EAA plastic resin 30707, and the melting point of the plastic is 102°C.

[0075] The operating process of this embodiment is the same as that of Example 1, and the operating parameters are: the linear speed is 30-50m / min, the temperature inside the box is 100-400°C, the oil temperature of the heating guide roller is 100-320°C, and the surface temperature of the heating guide roller is 80-400°C. 310°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com