Heat energy driven direct regeneration adsorb cooling cycle system

A technology of adsorption refrigeration and circulation system, which is applied in the field of adsorption refrigeration cycle and adsorption refrigeration system to achieve good heat exchange effect, efficient heat transfer and high refrigeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

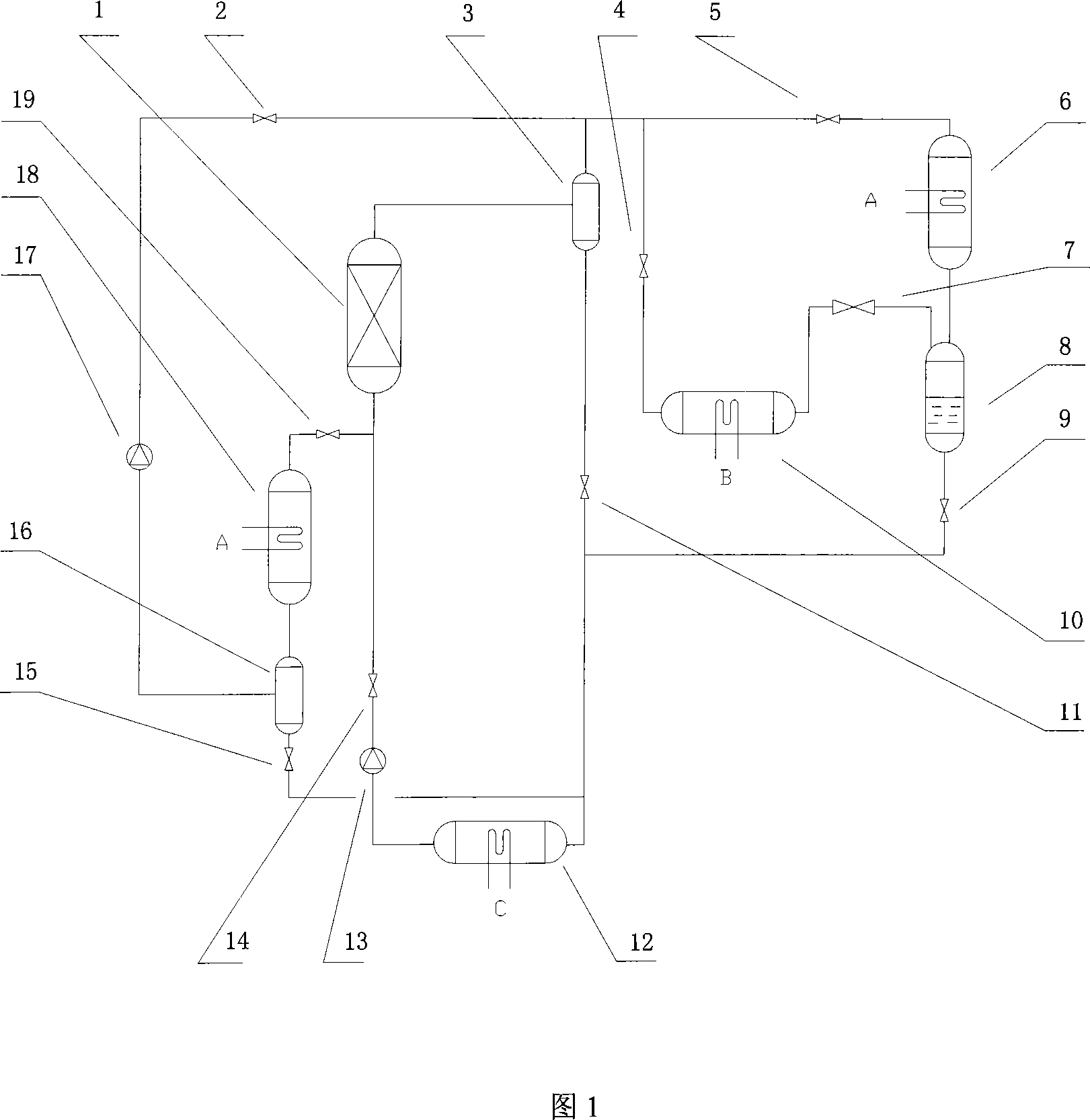

Image

Examples

Embodiment 1

[0026] The adsorber is filled with pure silicon Silicalite molecular sieve, the refrigerant is propane, the refrigerant evaporation temperature in the evaporator is -40°C, the evaporation pressure is 0.11MPa absolute pressure, the ambient temperature is 35°C, the adsorption temperature in the adsorber is 35°C, desorption The hot water temperature in the regeneration circuit is 85°C; the condensing pressure in the regeneration condenser is about 1.21MPa absolute pressure; the adsorption refrigeration and desorption regeneration cycle time are both 1.5min, the system refrigeration power is 250W / kg, and the refrigeration coefficient COP is 0.35.

Embodiment 2

[0028] The adsorber is filled with coconut shell activated carbon adsorbent, the refrigerant is n-butane, the evaporation temperature of butane refrigerant in the evaporator is 5℃, the evaporation pressure is about 0.15MPa absolute pressure, the ambient temperature is 40℃, and the adsorption temperature in the adsorber The temperature of the hot water in the desorption regeneration circuit is 95°C; the condensing pressure in the regenerative condenser is about 0.38MPa absolute pressure; the adsorption refrigeration and desorption regeneration cycle time are both 4min, the system refrigeration power is 180W / kg, and the coefficient of refrigeration is COP Is 0.43.

Embodiment 3

[0030] The adsorber is filled with pure silicon ZSM-5 molecular sieve, the refrigerant is isobutane, the refrigerant evaporation temperature in the evaporator is -10°C, the evaporation pressure is 0.11MPa absolute pressure, the ambient temperature is 35°C, and the adsorption temperature in the adsorber is 35℃, the temperature of hot water in the desorption regeneration circuit is 65℃; the condensing pressure in the regenerative condenser is about 0.46MPa absolute pressure; the adsorption refrigeration and desorption regeneration cycle time are both 2min, the system refrigeration power is 153W / kg, and the refrigeration coefficient COP is 0.42.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com