Gas sensor and method for manufacturing the same

A technology of a gas sensor and a manufacturing method, which is applied to the structural details of gas analyzers, analysis of gas mixtures, instruments, etc., can solve problems such as insufficient responsiveness of stability over time, and achieve excellent energy-saving effect, deterioration over time, and high efficiency. The effect of measuring sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

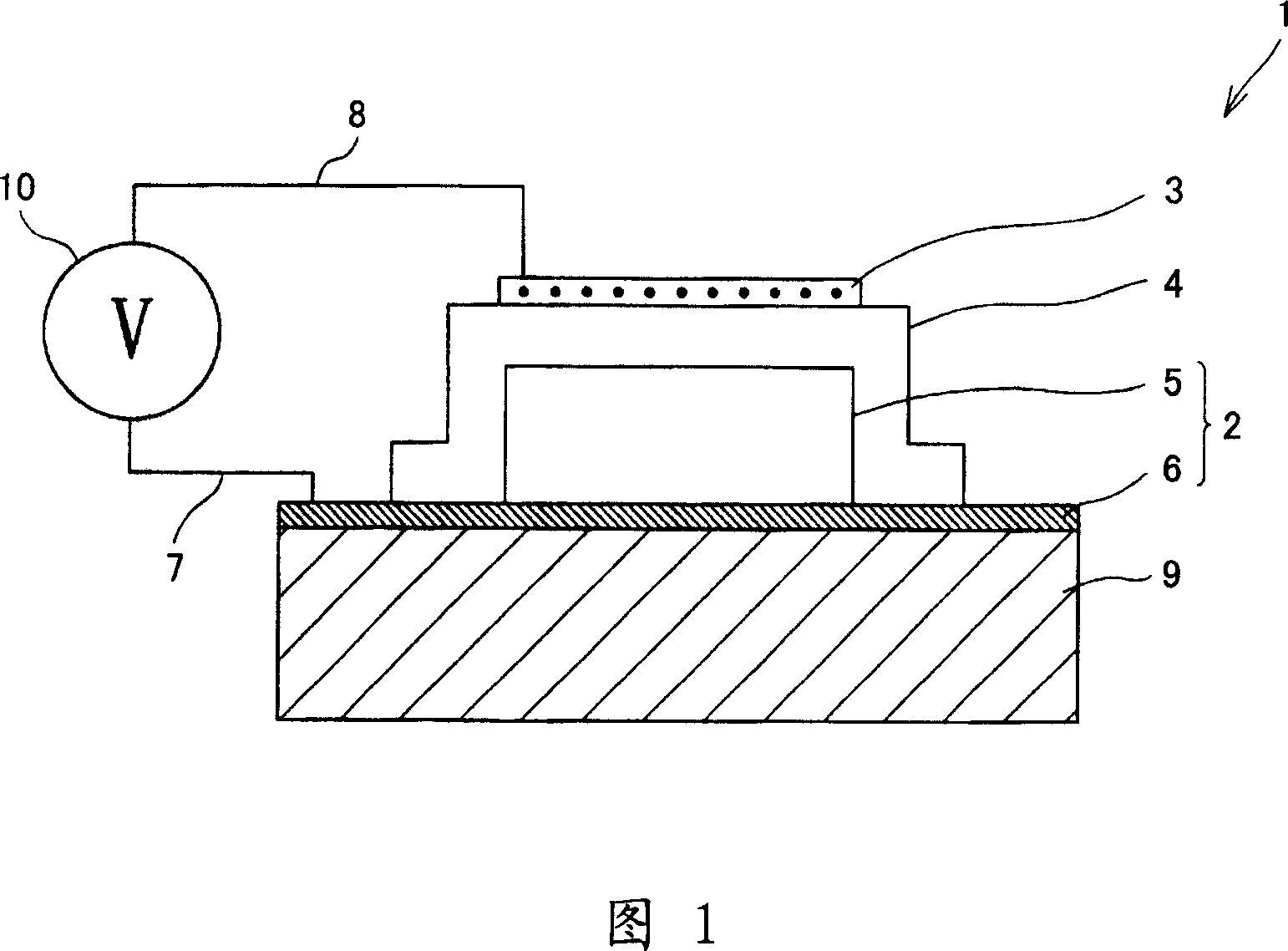

[0089] By vapor deposition at 10cm 2 1. A film-like substance of gold with a thickness of 0.1 μm is formed on the entire surface of a quartz glass substrate 9 with a thickness of 0.5 mm. Conductive substance film6.

[0090] Then, in an area of 2mm 2 A film-like material of lithium cobaltate with a thickness of 6 μm is formed on a part of the electronically conductive material film 6, and the part of the electronically conductive material film 6 corresponds to the 5 mm area on the back surface of the substrate 9 by laser ablation through the mask. 2 The central notch, thereby forming the reference material film 5. More specifically, lithium cobalt oxide powder molded into pellets by a mold is set in a vacuum container as a laser target, and a substrate 9 formed with an electronically conductive substance film 6 is set in a substrate holder in the vacuum container (substrate holder). Then, at 10 -3 A KrF excimer laser beam (eXcimer laser beam) was applied to the target un...

Embodiment 2~7

[0102] The gas sensors of Examples 2 to 7 were prepared under the same conditions as in Example 1, except that in order to change the ion conductivity level, La was changed as shown in Table 1. (2 / 3)-X Li 3X TiO 3 The Li content of the film (chemical formula La (2 / 3)-X Li 3X TiO 3 X in Table 1), and under the same conditions as in Example 1, the lithium ion migration number and sensor output were measured. Table 1 shows the results.

[0103] Table 1

[0104] La (2 / 3)-X Li 3X TiO 3 film

[0105] As can be understood from the results shown in Table 1, the gas sensors of Examples 2, 3 and 4 having X values in the range of 0.05 to 0.15 exhibited high levels of ion conductivity and particularly high output.

Embodiment 8~10

[0107] The gas sensors of Examples 8 to 10 were prepared under the same conditions as in Example 1, except that the reference substances shown in Table 2 were used, and the outputs of these gas sensors were measured under the same conditions as in Example 1. Table 2 shows the results. As can be understood from Table 2, the gas sensor obtained a high output regardless of the type of the reference substance.

[0108] Table 2

[0109] Reference substance

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com