Antibacterial dressings manufacturing method for medical purpose and uses thereof

A manufacturing method and technology of non-woven fabrics, applied in dressings, viscous dressings, medical science, etc., can solve the problems of not being able to maintain the fiber state, lowering the yield of carboxymethylated chitosan fibers, and not being able to process medical textiles, etc. Achieve the effect of promoting tissue healing and isolating bacterial infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

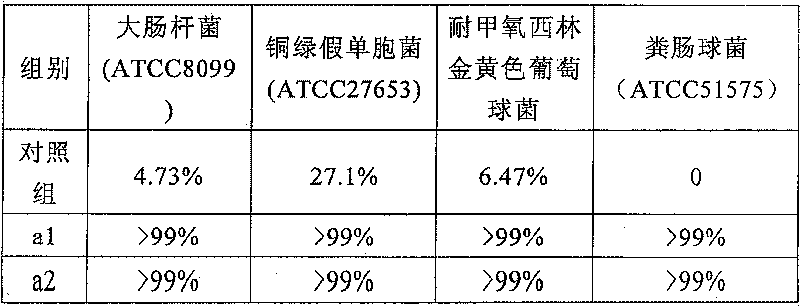

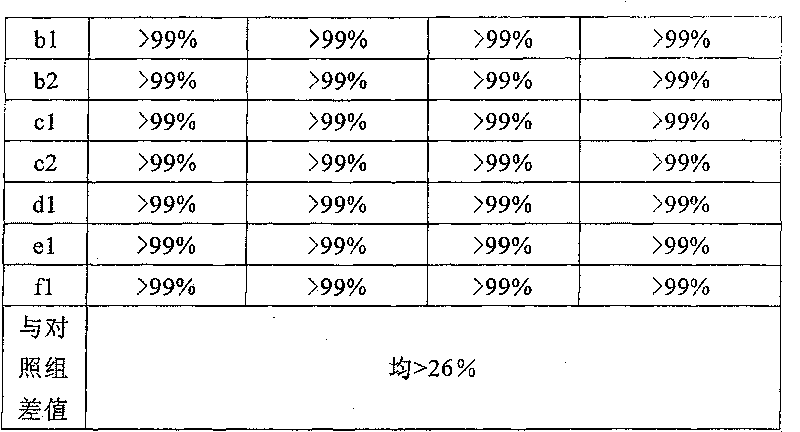

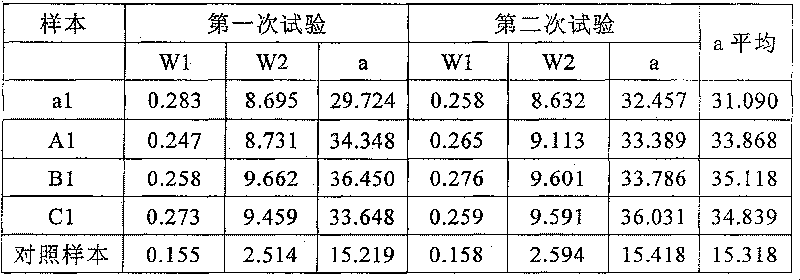

Examples

Embodiment 1

[0042] 100 grams of chitosan fibers are immersed in the concentration of 40% NaOH solution, bath ratio 1: 20, and reacted at room temperature for 0.5 hour to generate alkalized chitosan fibers; the product after alkalization is washed with absolute alcohol; The product is then reacted with chloroacetic acid in isopropanol, the concentration of chloroacetic acid is 20%, the reaction temperature is 35°C, and the reaction time is 1 hour. After the reaction is completed, the excess solution is removed, washed with absolute ethanol, and air-dried to form a carboxymethyl shell. polysaccharide fibers. This product is made into 50 g / m by cutting, opening, netting and needle punching 2 The non-woven fabric can be made into a dressing after cutting, packaging and disinfection, which is called a1. Suitable for wounds less than 10cm 2 the wound.

Embodiment 2

[0044] According to the mass ratio of 9:1, the chitosan fiber and the carboxymethyl chitosan fiber used in the preparation of a1 are mixed, opened, netted, and needle-punched to make 100 g / m 2 Non-woven fabric, which can be made into a dressing after cutting, packaging, and disinfection, is called a2. It is suitable for burns and scalds with relatively large trauma.

Embodiment 3

[0046] 100 grams of chitosan fibers are immersed in a concentration of 45% NaOH solution, the bath ratio is 1: 40, and reacted for 1 hour at room temperature to generate alkalized chitosan fibers; the alkalized product is washed with absolute alcohol; The product is then reacted with chloroacetic acid in isopropanol, the concentration of chloroacetic acid is 30%, the reaction temperature is 60°C, and the reaction time is 3 hours. After the reaction is completed, the excess solution is removed, washed with absolute ethanol, and air-dried to form a carboxymethyl shell. polysaccharide fibers. This product is made into 50 g / m by cutting, opening, netting and needle punching 2 Non-woven fabrics can be made into dressings after cutting, packaging and disinfection, called b1. Suitable for wounds less than 10cm 2 the wound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com