Nickel alloy and method of direct aging heat treatment

A nickel-based alloy, direct technology, applied in the field of nickel-based alloys and direct-aged nickel-based alloys, which can solve problems such as poor machinability and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In a first embodiment, the solution treated and aged 718Plus Mechanical Properties of Alloys Compared to Directly Aged 718Plus According to a Non-limiting Embodiment of the Invention Disclosure The mechanical properties of the alloys were compared. The mechanical properties of the 3 processing conditions were tested and the result was a particle size variation from 12 to 7 with ASTM in the product. The results are listed in Table 1 - Solution-aged and direct-aged 718Plus manufactured with different processing conditions Comparison of mechanical properties between alloy products. SA = solution aged, DA = direct aged, AC = air cooled, FC = furnace cooled and CW = cold worked.

[0047] The 718Plus of this embodiment Alloy samples were manufactured as follows. Solution treated and aged alloy samples were solution treated by heating at 954°C (1750°F) for 1 hour, followed by air cooling. Then, the sample was aged at 788°C (1450°F) for 2 hours, cooled from 788°C ...

Embodiment 2

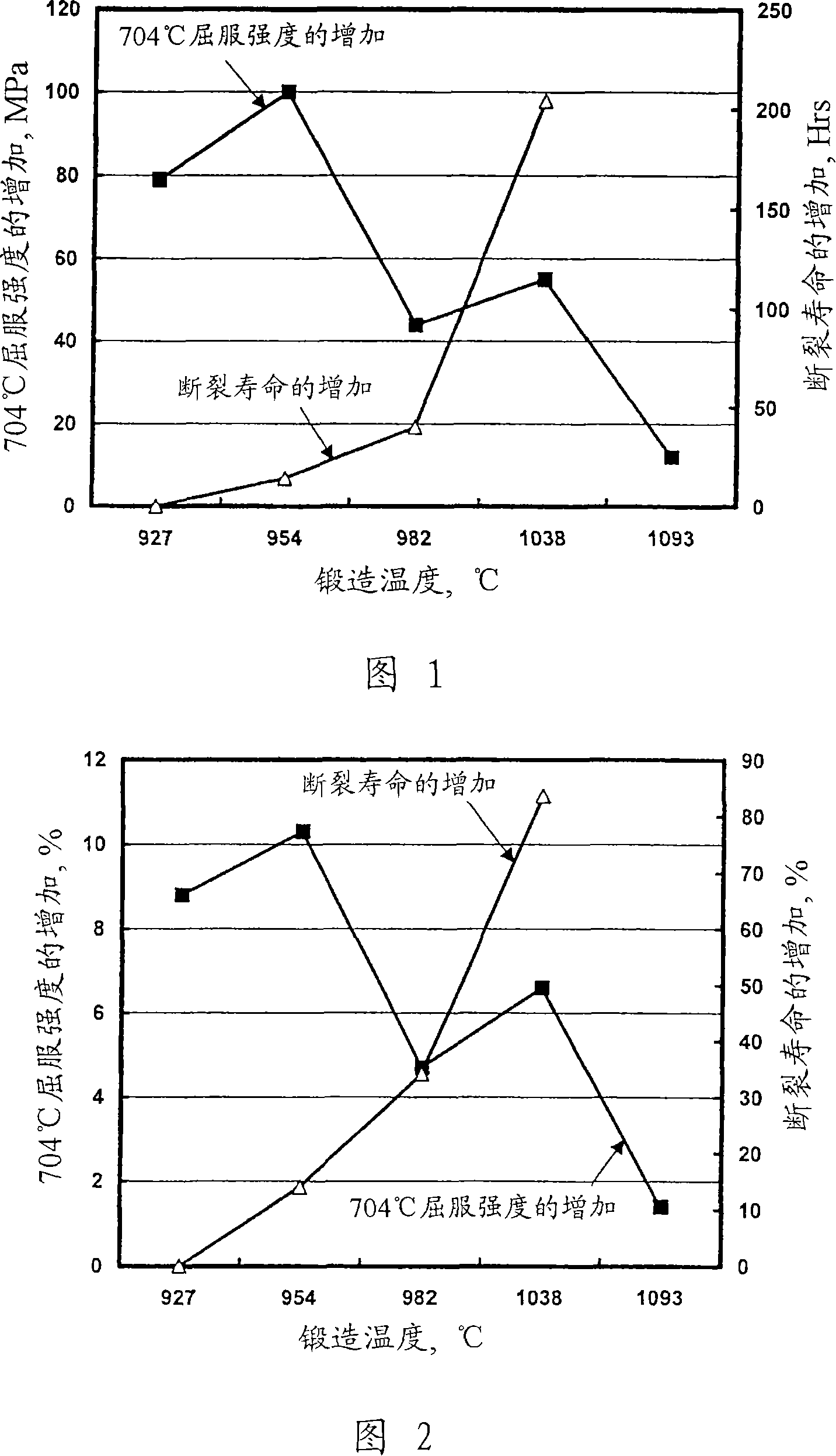

[0056] This example was designed to measure satisfactory processing conditions for various non-limiting embodiments of the method of the present invention. In this example, from 718Plus A 25.4 cm diameter round billet of nickel base alloy was cut into two sets of four 5.08 cm x 5.08 cm x 5.08 cm cubes. The cube was heated to a series of different temperatures between 927°C (1700°F) and 1093°C (2000°F). Then, all cubes are processed as follows. First, the cubes were reduced to a thickness of 3.81 cm in the first rolling pass and further reduced to a thickness of 2.54 cm in the second rolling pass after reheating to the specified processing temperature. Flat cubes (or "pancakes") 2.54 cm thick were reheated for approximately 0.5 hours at a finish forging temperature range of 1093°C (2000°F) to 927°C (1700°F) (as shown in Table 2), and rolled In the manufacturing pass, it was further reduced to a 1.27 cm thick wafer (50% reduction in the final working rolling pass). The res...

Embodiment 3

[0065] This example is designed to determine the effect of heating time on a 718Plus at a thermal processing temperature Effects on the mechanical properties of nickel-based alloys. This test is carried out due to the rather long heating times in some industrial practices, especially for heavy billets with large cross-sections. 718Plus Nickel-base alloy samples were heated at the forging temperature of 927°C (1700°F) or 954°C (1750°F) for 0.5 hours or 3 hours. Half of the samples were then solution treated and aged as outlined in Example 1. The other half of the samples were directly aged according to a non-limiting embodiment of the invention as described in Example 1.

[0066] Tensile testing was performed at 704°C (1300°F) and stress-rupture testing at 704°C (1300°F) and 552 MPa (80 ksi). Table 3 lists the results of the effect of forging temperature - the effect of heating time at forging temperature on the effect of direct aging.

[0067] The results shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com