Impulse melting mass spectrometry analysis method for element

A technology of elemental analysis and mass spectrometry, which is applied in the field of quantitative analysis of the chemical composition of materials, can solve the problems of complex analysis process, must be detected one after another, and cannot be analyzed at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

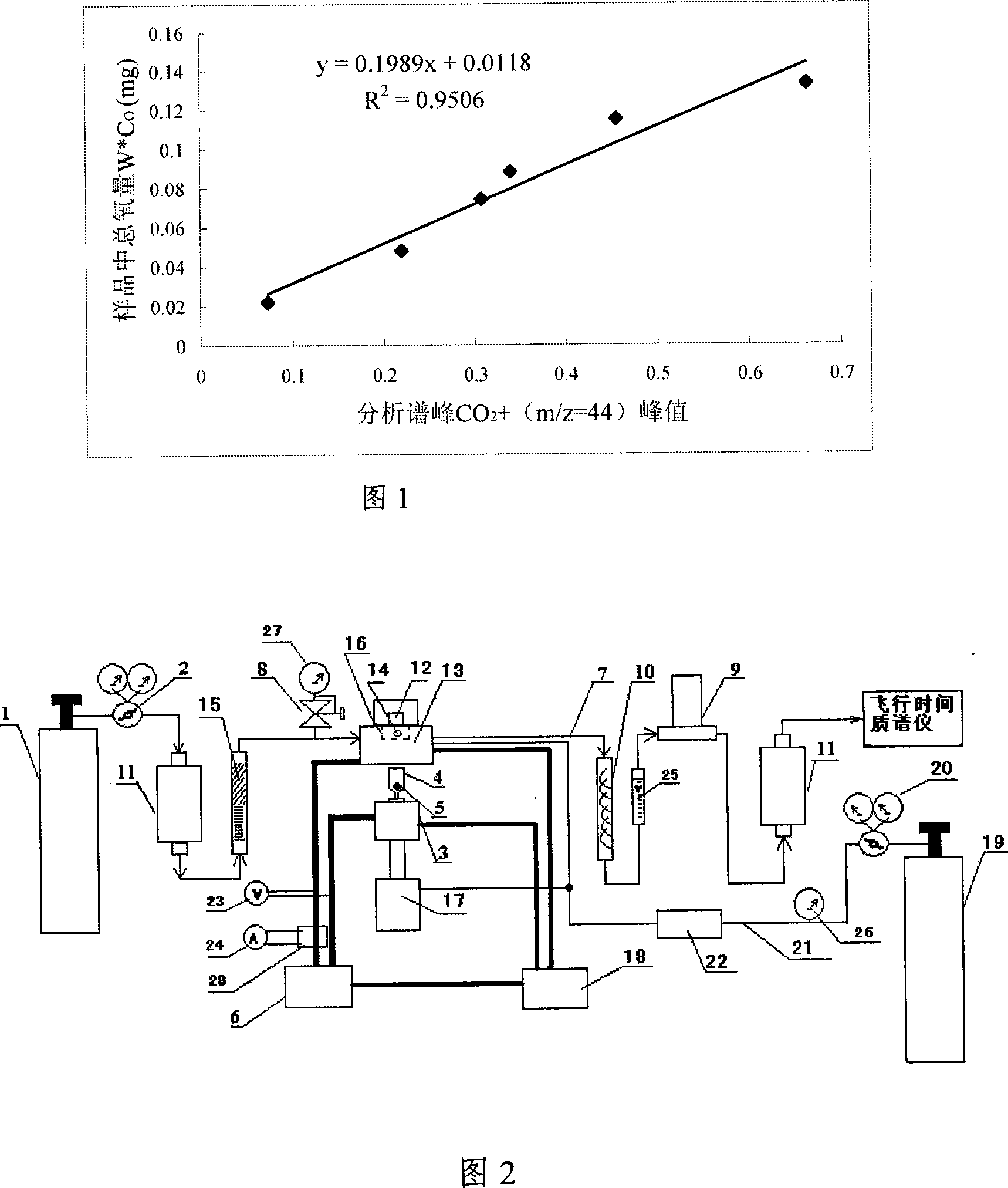

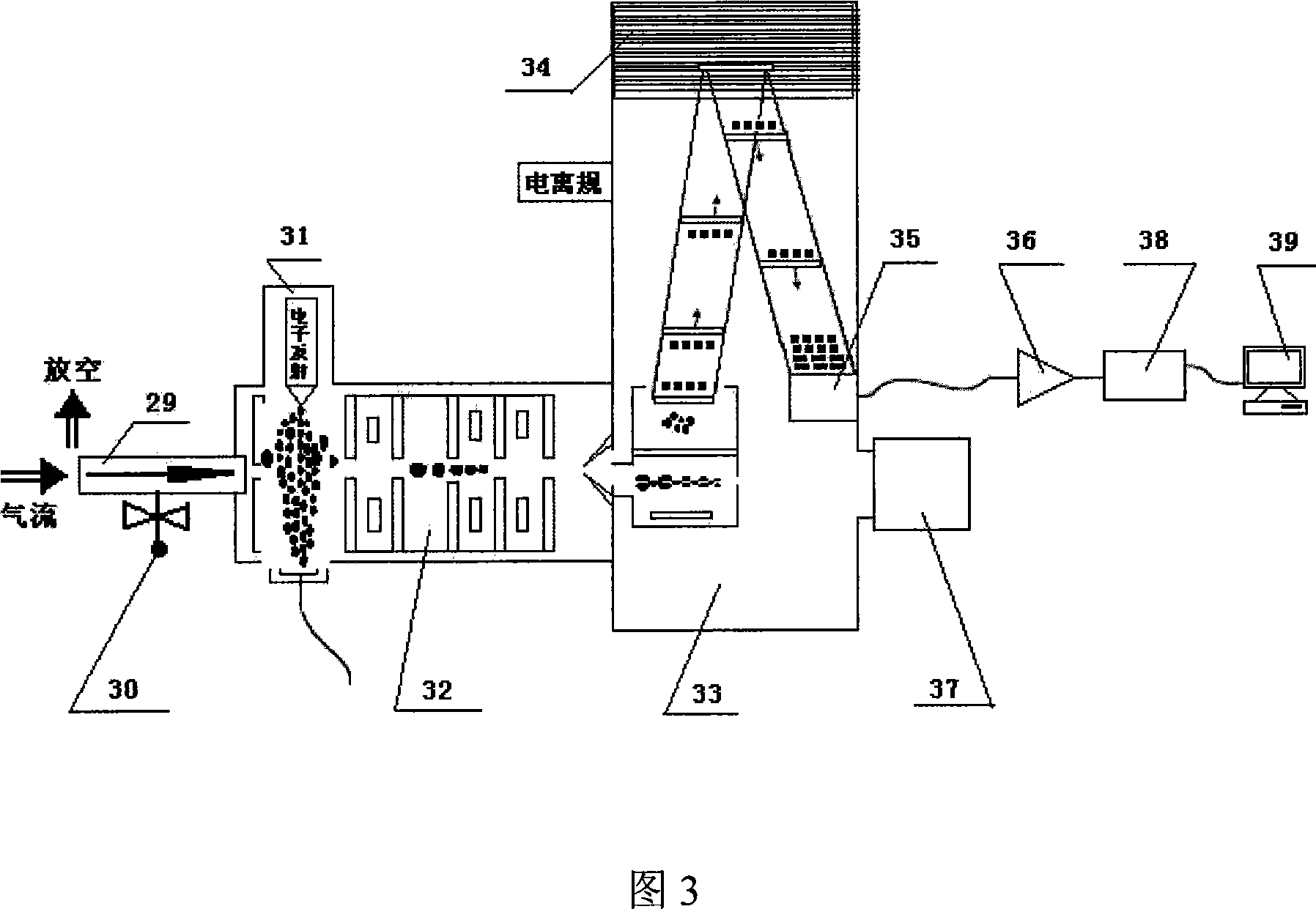

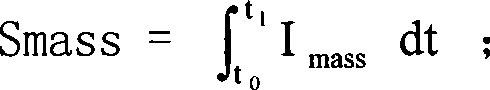

[0064] The implementation of the present invention must use the pulse fusion mass spectrometer elemental analyzer (applied for invention patent). The elemental analyzer consists of a pulse heating furnace, a sampling system, a purification device, a mass spectrometer, a signal acquisition and data processing system, and an automatic control system. The pulse heating furnace and the sample feeding system are integrated through the upper and lower electrodes and the upper and lower cylinders to form a closed furnace, and the samples are put into the graphite crucible between the upper and lower electrodes during analysis; The instruments are connected to each other by gas pipelines: the purified inert carrier gas is introduced from the bottom of the furnace, and the gas components released by the melting of the sample are carried out, and then purified and passed into the mass spectrometer. The signal acquisition and data processing system is connected to the detector of the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com