Method for making three-dimension electric casting micro structure

A manufacturing method and microstructure technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of not processing micro switches, etc., and achieve small internal stress, good verticality of side walls, and structural strength high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

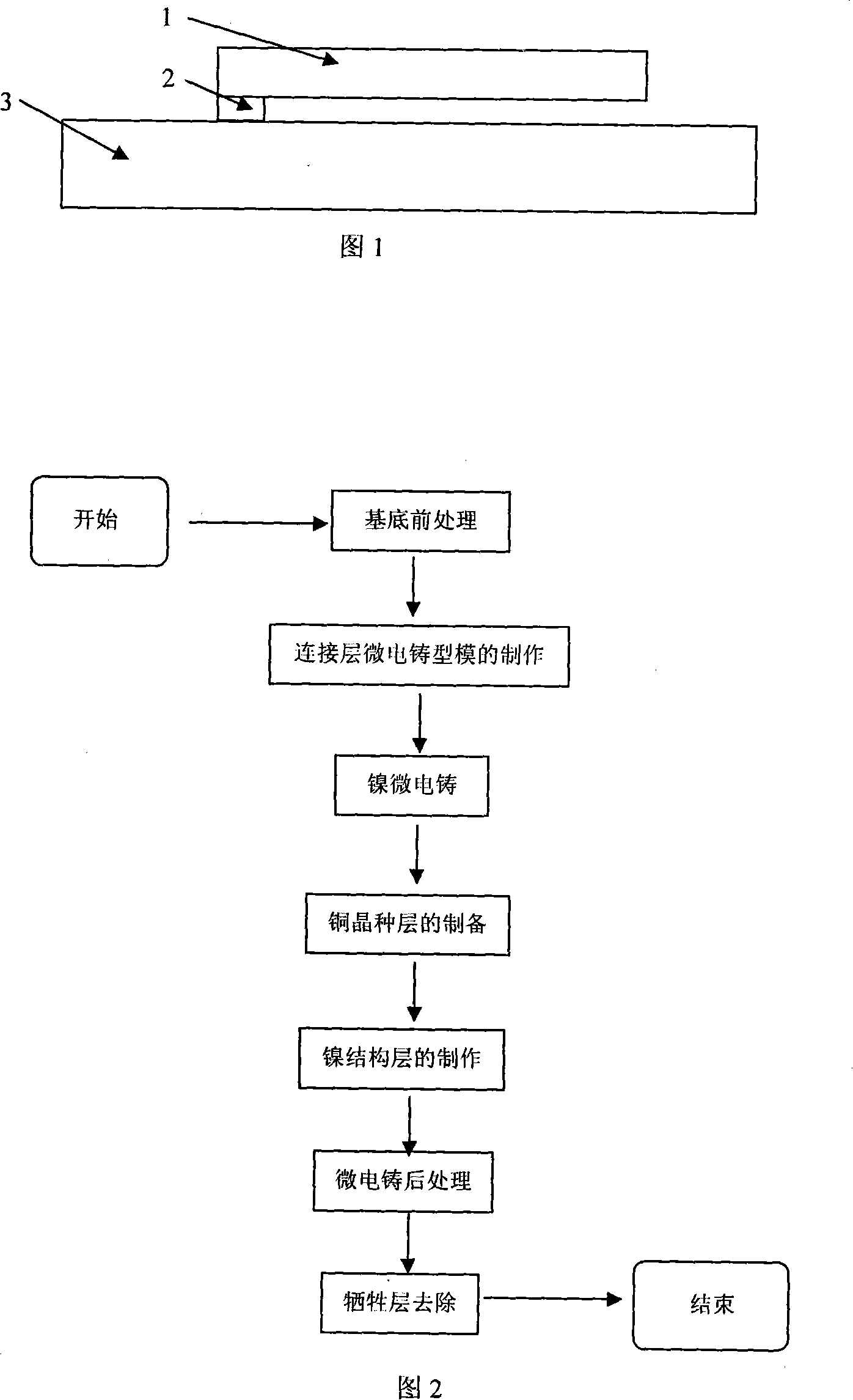

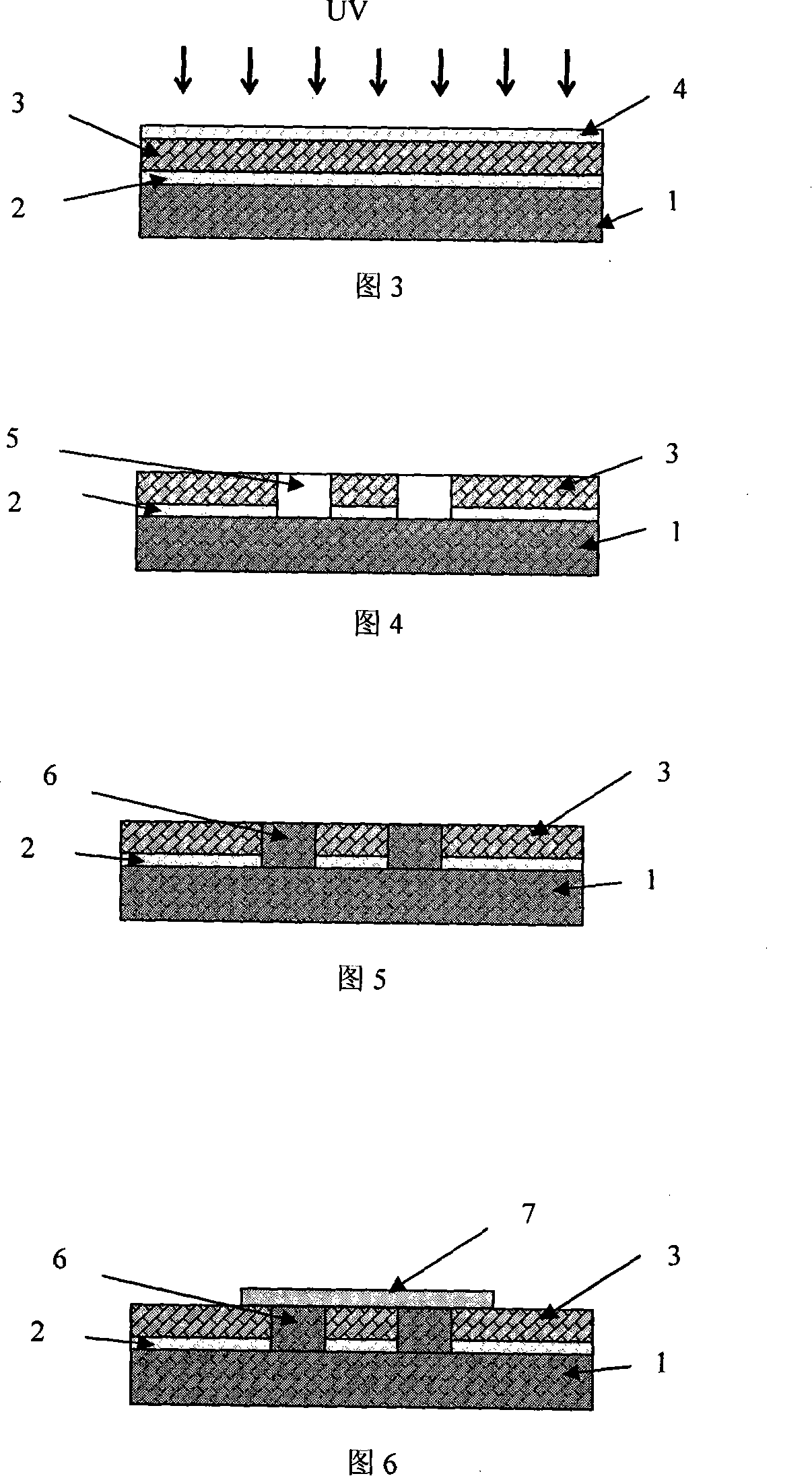

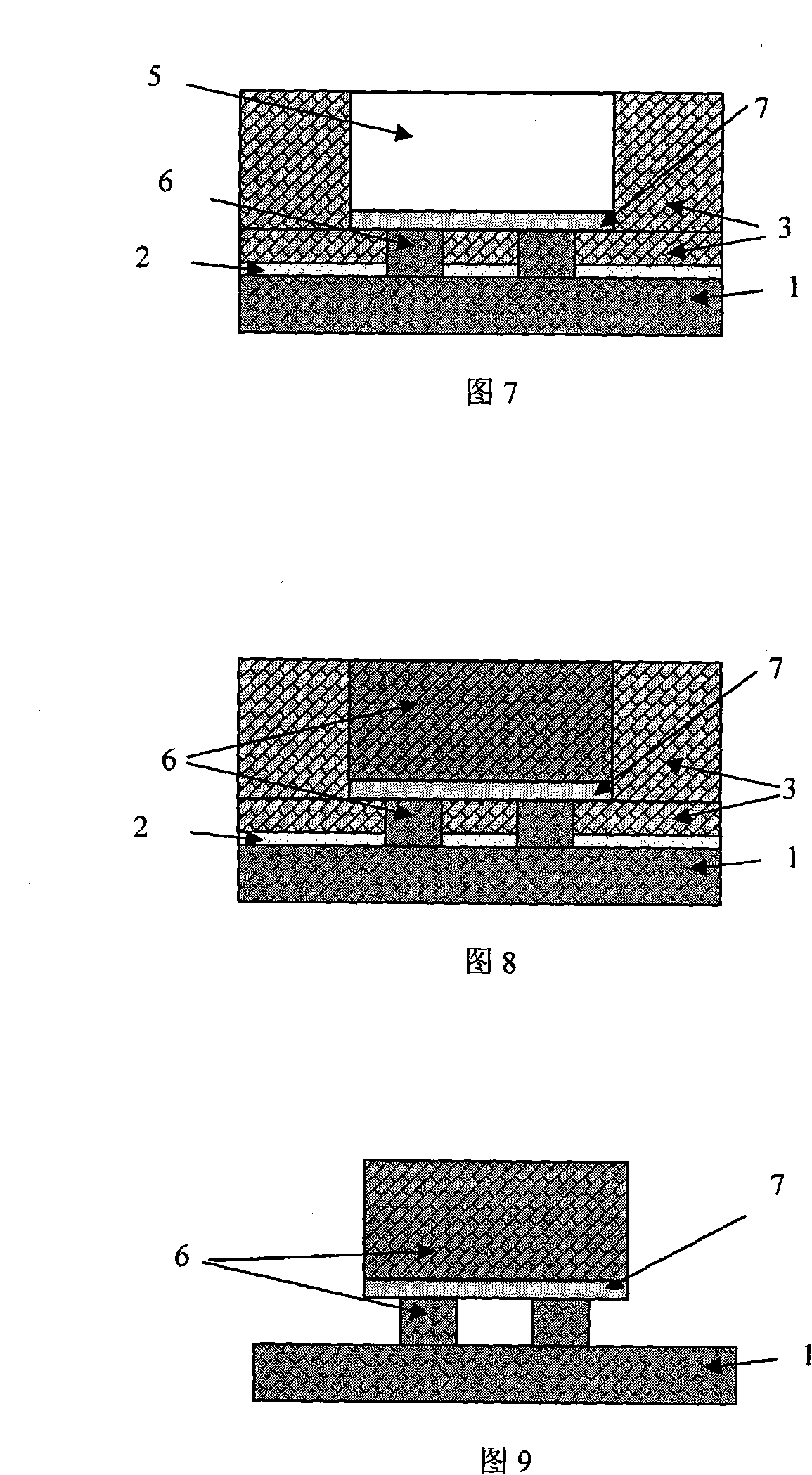

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings. For example: electroform a "cantilever" shape on a high-purity nickel substrate (53mm×63mm×2mm) after fine grinding and polishing (the size of the cantilever part 1 is 15mm×100um×300um, the connection layer 2 between the cantilever 1 and the substrate 3 Size is 100um * 100um * 50um, see the three-dimensional microstructure of accompanying drawing 1), it makes this structure according to the specific steps of flow chart 2 as follows:

[0017] 1. Substrate pretreatment The substrate material is high-purity nickel metal. The pretreatment of the nickel substrate is divided into two parts: mechanical processing pretreatment and surface cleaning. The mechanical processing pretreatment includes: milling, grinding, fine grinding, wire cutting and polishing. , The surface cleaning adopts the organic solvent degreasing method, and the organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com