Sealing device used for 10(-8)Pa ultra-high vacuum round plane magnetron sputtering target

An ultra-high vacuum and magnetron sputtering technology, which is applied in the sealing of engines, sputtering coating, vacuum evaporation coating, etc., can solve the problems of air leakage, water seepage, poor reflectivity, and poor solderability in the packaging, and achieve Easy to repair and replace, ensure the tightness, and ensure the effect of the tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

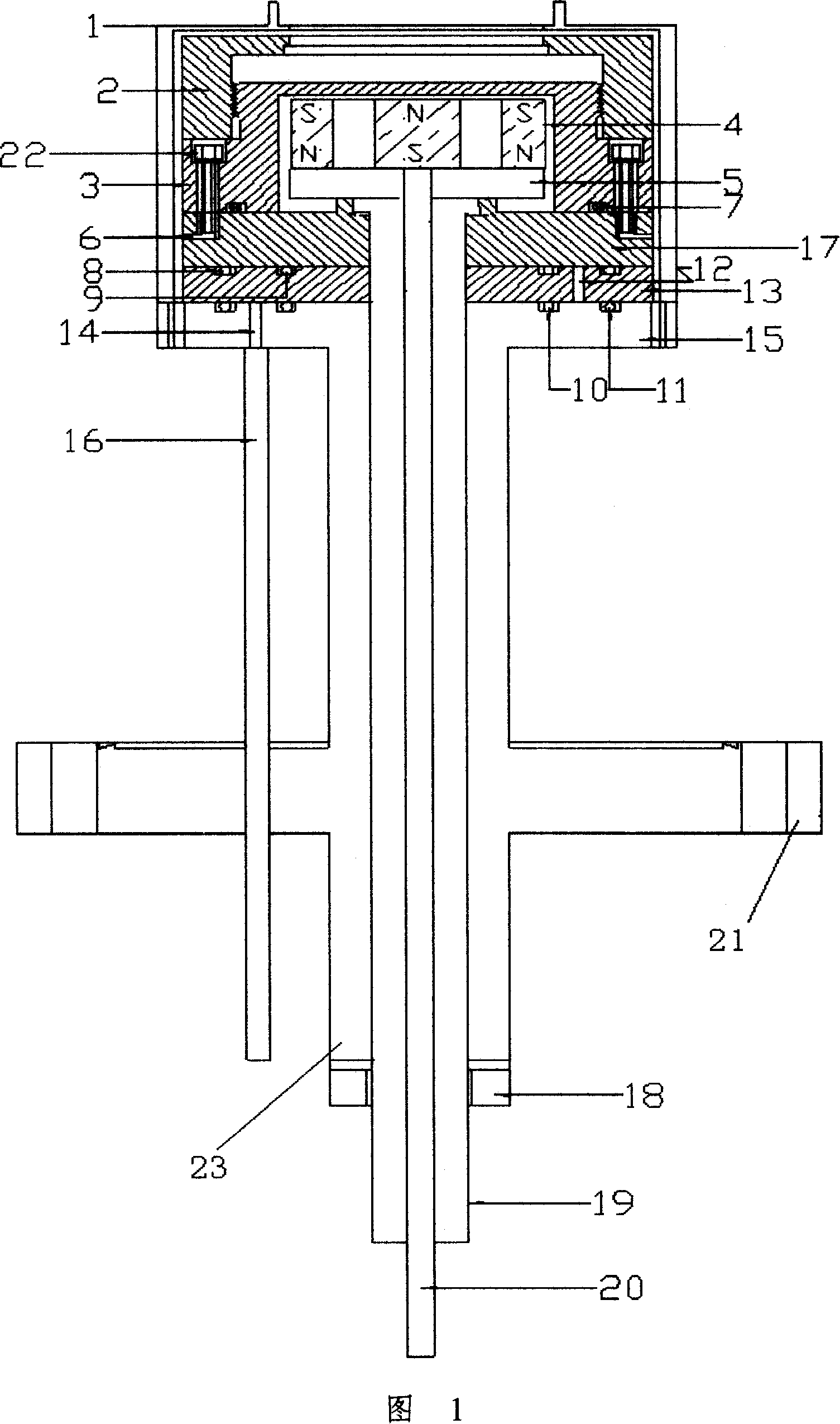

[0010] Referring to Fig. 1, soft iron 5 and magnetic steel 4 are built in the cavity of the water cooling chamber 3, the upper end of the water cooling chamber 3 is connected with the target mounting cover 2 through mutual threaded connection, and the lower end surface is connected with the water cooling chamber A ○-shaped metal sealing ring 7 composed of an aluminum wire sealing ring is placed between the upper end faces of the sealing flange 17 , and is fixedly connected by screws 22 . A through hole 6 is arranged on the side wall of the sealing flange 17 of the water cooling chamber, and one end of the through hole 6 communicates with the bottom of the screw 22 hole, and the other end communicates with the vacuum chamber. The water inlet pipe 20 sleeved in the water outlet pipe 19 passes through the soft iron 5 and is welded thereto. The outlet pipe 19 penetrates through the sealing flange 17 of the water cooling chamber and is welded to it. The upper end of the sealing fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com