Progesterone injection and method for preparing the same

A progesterone and injection technology, applied in the field of progesterone injection and its preparation, can solve the problems such as the sterilization temperature cannot be higher than 105 DEG C, the solubility problem of progesterone cannot be solved, the sterilization time cannot be longer than 15 minutes, and the like, To achieve the effect of reducing local injection irritation and allergic side effects, reducing hemolysis and histamine release, and improving drug efficacy and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: preparation content is the progesterone submicron emulsion of 0.5% (being 5mg / ml)

[0043] Prescription 1 Progesterone 5g

[0044] Soybean oil (injection grade) 180g

[0045] Polyethylene glycol 15-hydroxystearate 18g

[0046] Soy Lecithin (Injection Grade) 2g

[0047] Glycerin (injection grade) 2g

[0048] Oleic acid 5g

[0049] Vitamin E 0.3g

[0050] Water for injection to 1000ml

[0051] Dissolve 5g of progesterone in 180g of soybean oil, vitamin E and 5g of oleic acid as the oil phase, stir continuously and heat to 70°C, add 18g of polyethylene glycol 15-hydroxystearate (solutol HS15), 2g of soybean lecithin, Disperse 2g of glycerin in water as the water phase, heat it to 70°C with constant stirring, slowly add the oil phase to the water phase, stir at high speed with a high-speed disperser for 8 minutes (rotation speed 20,000 rpm) to prepare colostrum, and use high-pressure Homogenize with a homogenizer (pressure 65MPa, temperature 75°C) for 7...

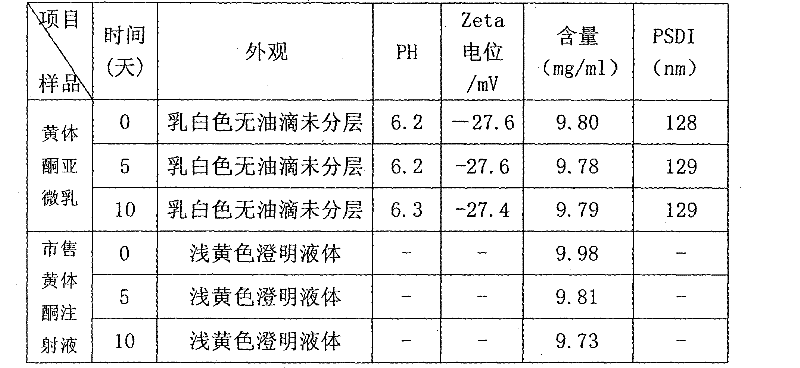

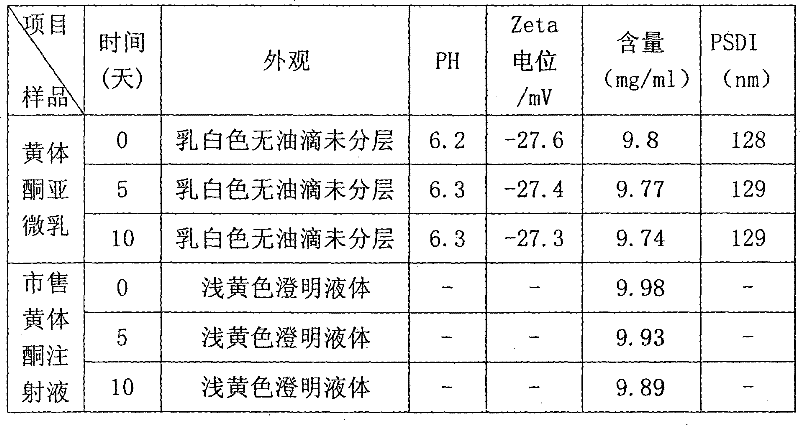

Embodiment 2

[0054] The preparation content is the progesterone submicron emulsion of 1% (being 10mg / ml)

[0055] Prescription 2 Progesterone 10g

[0056] Soybean oil (injection grade) 180g

[0057] Polyethylene glycol 15-hydroxystearate 18g

[0058] Soy Lecithin (Injection Grade) 2g

[0059] Glycerin (injection grade) 2g

[0060] Oleic acid 5g

[0061] Ascorbic acid 0.1g

[0062] Water for injection to 1000ml

[0063] 10g of progesterone was dissolved in 180g of soybean oil and 5g of oleic acid as the oil phase, and heated to 70°C with constant stirring, 18g of polyethylene glycol 15-hydroxystearate (solutol HS15), 2g of soybean lecithin, 2g of glycerin, Ascorbic acid is dispersed in water as the water phase, heated to 70°C with constant stirring, the oil phase is slowly added to the water phase, and the colostrum is prepared after 8 minutes of high-speed stirring with a high-speed disperser (rotation speed 20000 rpm), and the colostrum is homogenized with high pressure After homog...

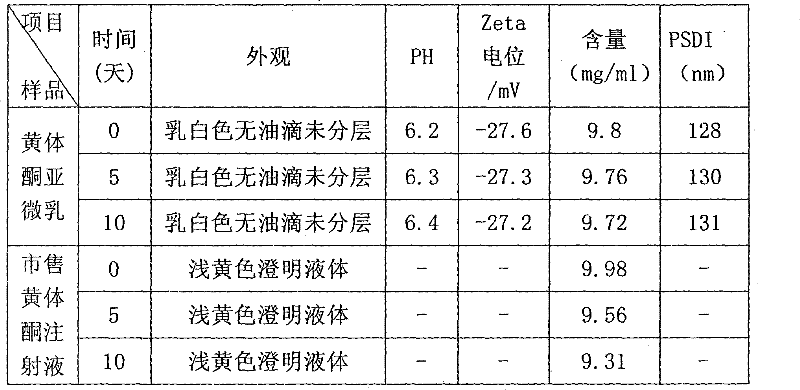

Embodiment 3

[0066] Preparation content is the progesterone submicron emulsion of 2% (being 20mg / ml)

[0067] Prescription 3 Progesterone 20g

[0068] Soybean oil (injection grade) 180g

[0069] Polyethylene glycol 15-hydroxystearate 18g

[0070] Soy Lecithin (Injection Grade) 2g

[0071] Glycerin (injection grade) 2g

[0072] Oleic acid 5g

[0073] Hexasodium Phytate 0.5g

[0074] Water for injection to 1000ml

[0075] Dissolve 20g of progesterone in 180g of soybean oil and 5g of oleic acid as the oil phase, stir continuously and heat to 70°C, add 18g of polyethylene glycol 15-hydroxystearate (solutol HS15), 2g of soybean lecithin, 2g of glycerin, Disperse hexasodium phytate in water as the water phase, heat it to 70°C with constant stirring, slowly add the oil phase to the water phase, stir at high speed with a high-speed disperser for 8 minutes (speed 20,000 rpm) to prepare colostrum, and mix the colostrum Homogenize with a high-pressure homogenizer (pressure 65MPa, temperature 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com