Anti-impact ferrous rare earth permanent magnet and its manufacturing method

A rare earth permanent magnet, impact resistance technology, applied in the direction of magnetic objects, magnetic materials, inorganic material magnetism, etc., can solve the problems of poor impact resistance, expanded material application range, easy to drop edges and corners, etc., to improve impact resistance. , the effect of improving machinability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

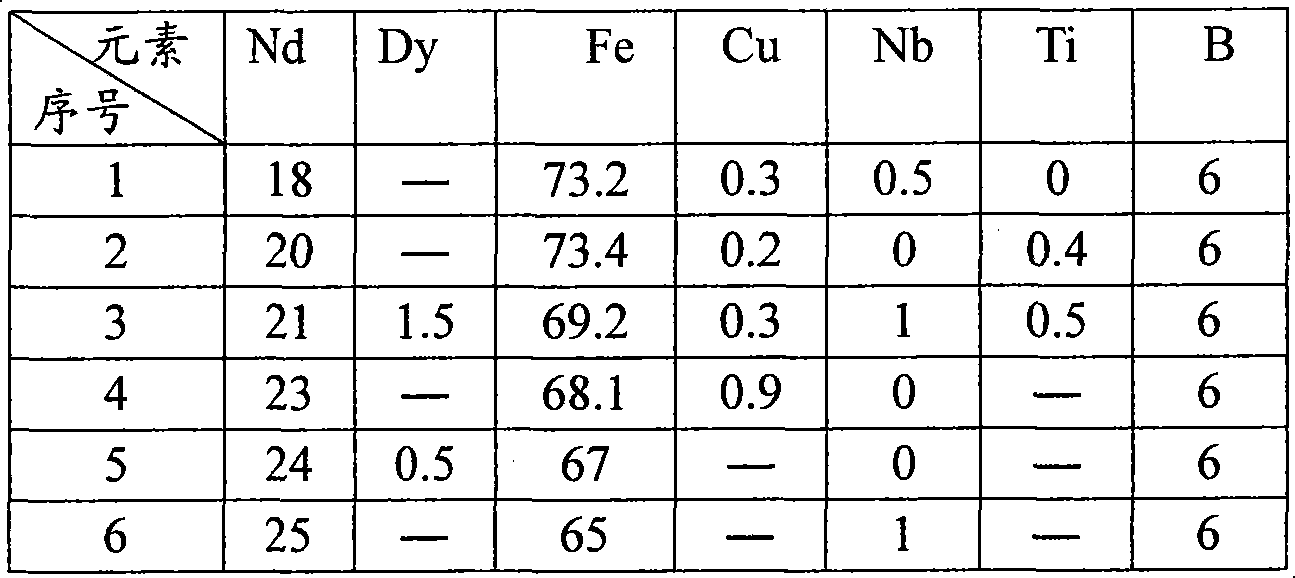

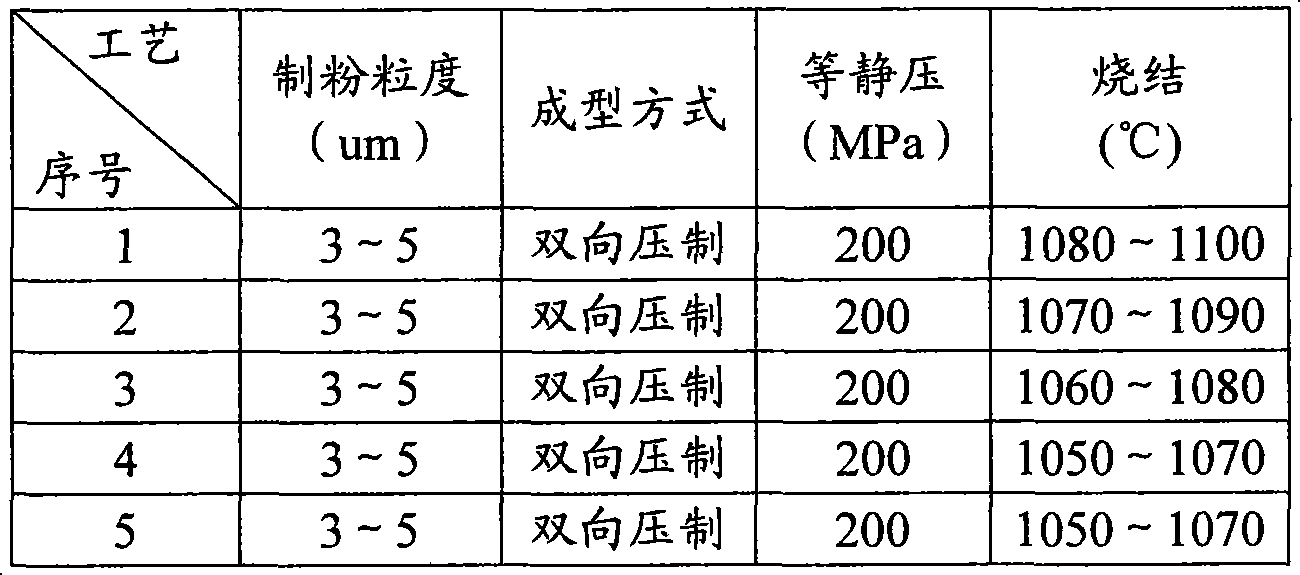

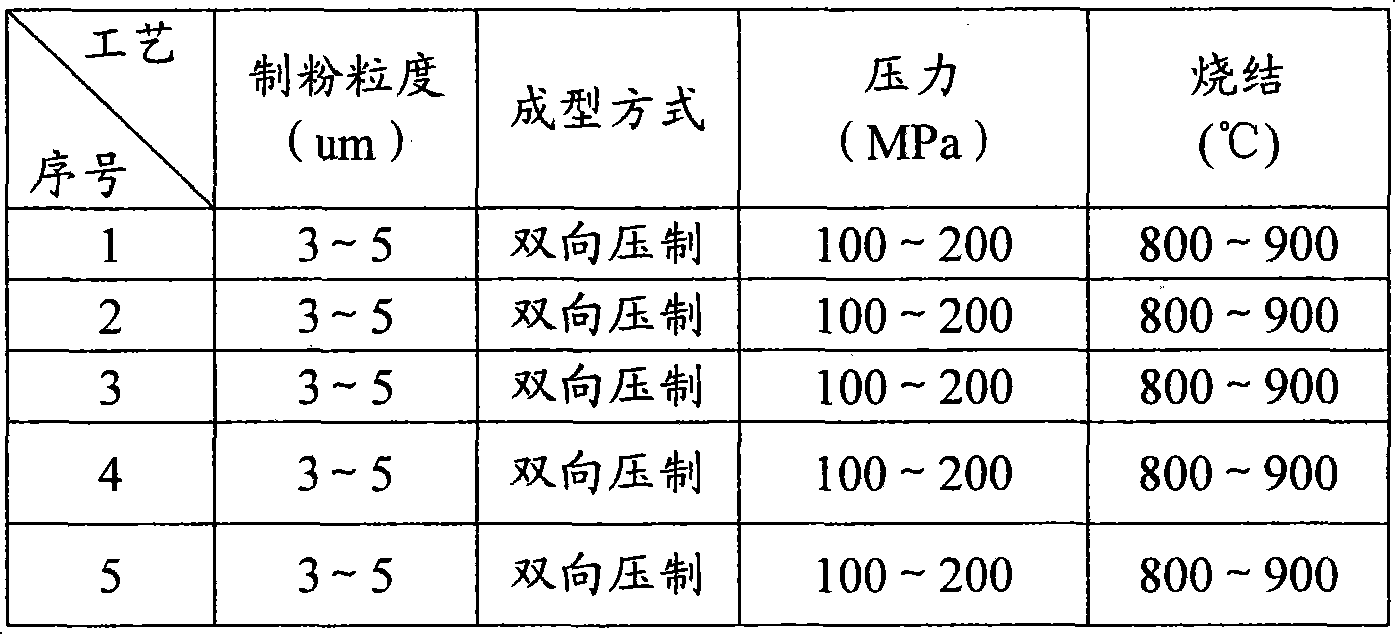

[0064] Table 1 is the specific chemical composition of the alloy of the impact-resistant iron-based rare earth permanent magnet of the present invention; Table 2, 3 and 4 are the preparation process of the impact-resistant iron-based rare earth permanent magnet of the present invention; Table 5 is the items of the embodiments of the present invention Performance comparison table with prior art performance; Table 6 is a comparison of the magnetic properties and impact resistance of commonly used magnets by the drop weight method, where the size of the sample is Φ10×4mm 2 ; Table 7 is a comparison of permanent magnets of the present invention and FeCrCo machinable permanent magnetic properties.

[0065] Table 1: Chemical composition (atomic %) of the anti-shock iron-based rare earth permanent magnet material of the embodiment of the present invention

[0066]

[0067] Table 2: Preparation process of impact-resistant iron-based rare earth permanent magnet material according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com