Substrate processing device and method

A substrate processing device and technology for substrates, which are applied in chemical instruments and methods, special processing targets, cleaning methods and utensils, etc., can solve problems such as difficulty in size and inability to provide large quantities of sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0031]

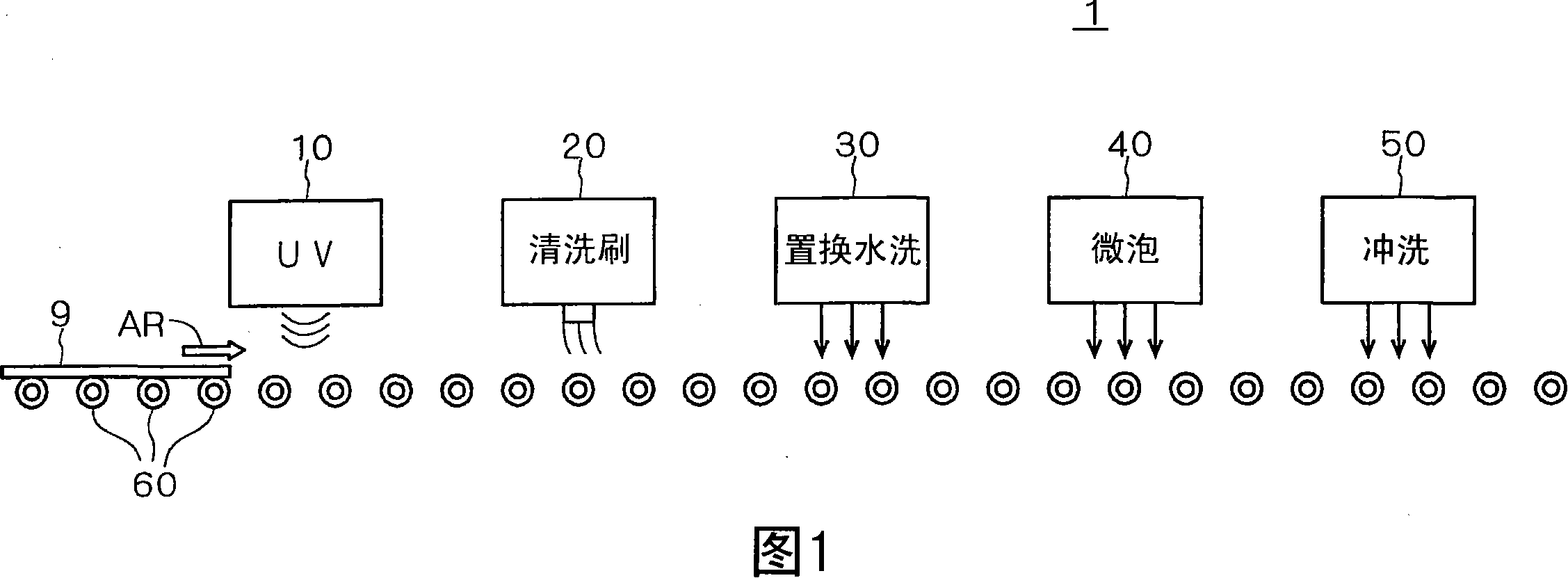

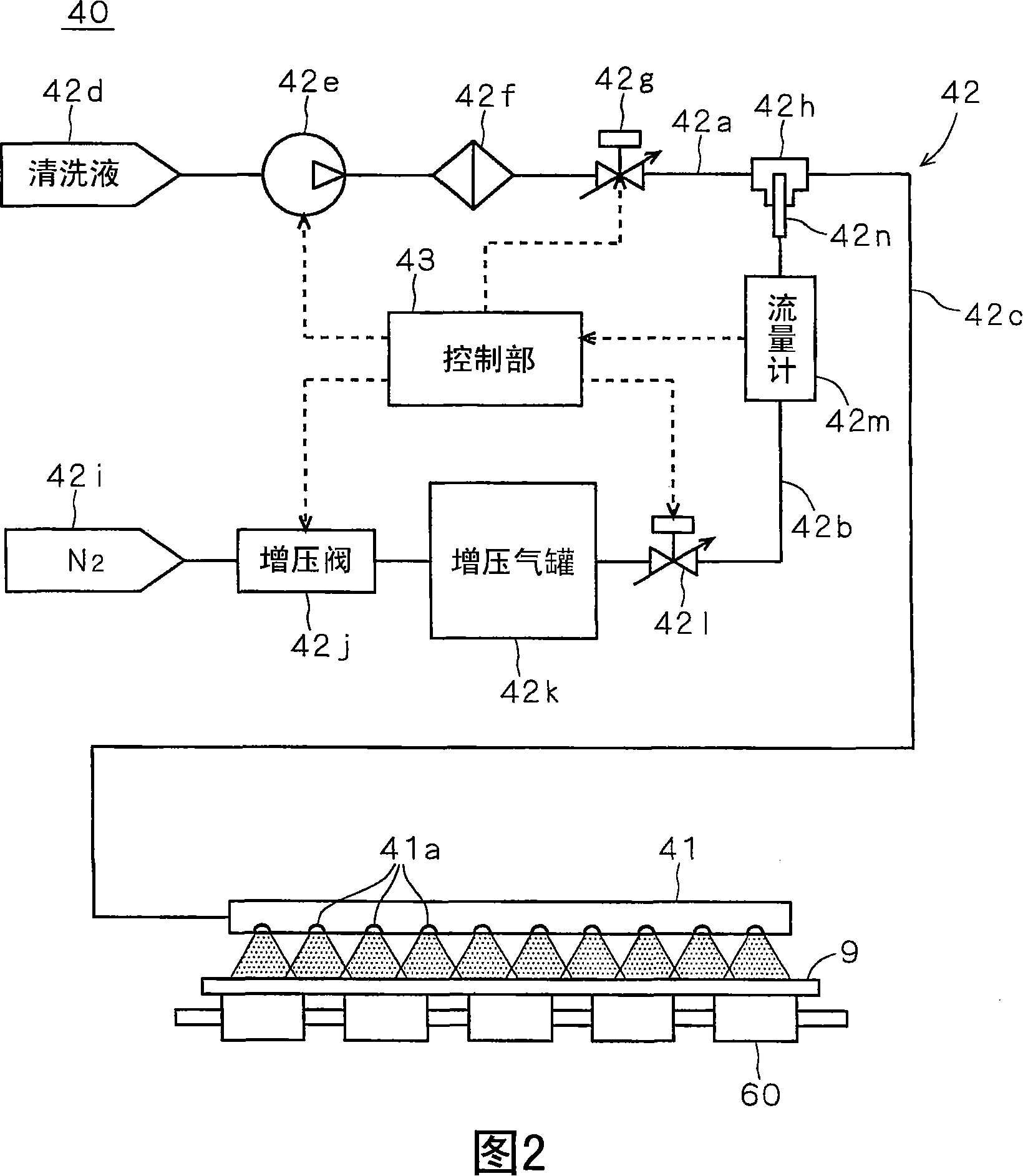

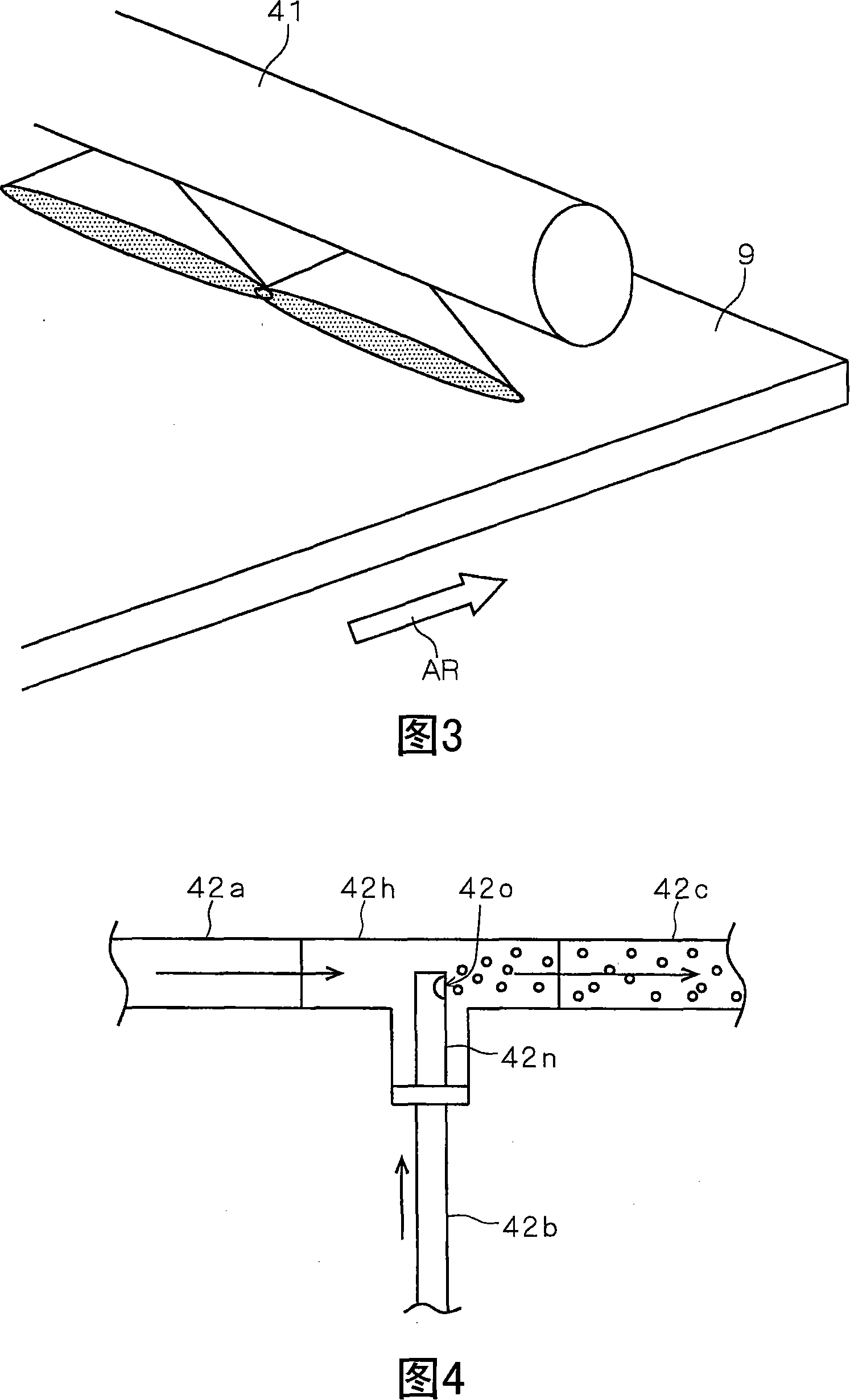

[0032] FIG. 1 is a view schematically showing the overall structure of a substrate processing apparatus 1 of the present invention. The substrate processing apparatus 1 is an apparatus for cleaning the surface of a square glass substrate (hereinafter simply referred to as “substrate”) 9 for a liquid crystal display device and removing foreign matter such as organic matter or particles adhering to the substrate 9 . As shown in FIG. 1 , the substrate processing apparatus 1 mainly includes a UV processing unit 10 , a cleaning brush processing unit 20 , a replacement washing unit 30 , a microbubble cleaning processing unit 40 , and a rinsing processing unit 50 . Furthermore, the substrate processing apparatus 1 includes a plurality of transport rollers 60 for transporting the substrate 9 , and the substrate 9 is transported in the arrow AR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com