Double-sided pulse ionization investigation apparatus

A bidirectional pulse and detector technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of anode sputtering consumption, cathode pollution, etc., and achieve the effects of avoiding performance degradation, reducing pollution, and strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

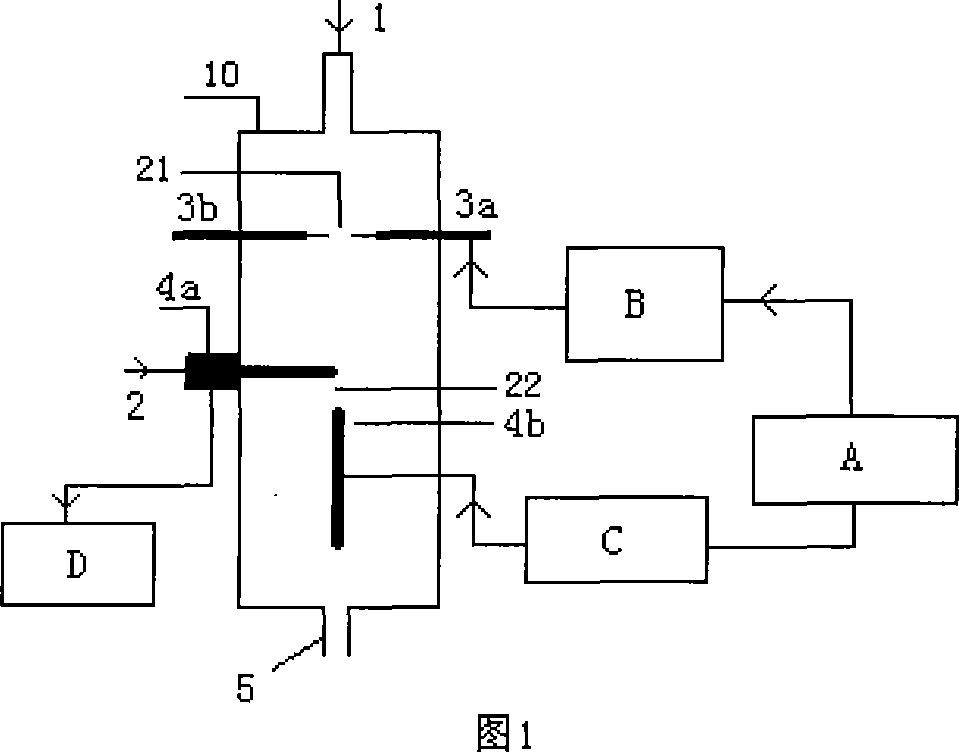

[0019] As shown in Figure 1: high-purity helium (99.9995%) enters the discharge chamber (21) through the discharge gas inlet (1), and the single-chip microcomputer (A) controls the high-voltage power supply (B) to provide stable bidirectional power to the discharge electrodes (3a, 3b) Pulse high voltage, working frequency 20kHz, duty ratio 1:5, pulse width 25μs, period 200μs and pulse amplitude 1000V, the distance between the discharge electrodes is 1mm, helium is discharged in the discharge chamber to generate plasma, and the sample gas inlet ( 2) The incoming sample gas collides, and the sample gas and high-energy particles are ionized after colliding in the ionization chamber (22), and the single-chip microcomputer (A) controls the DC power supply (C) to plate the gold-plated collecting electrode (4a) on the copper surface, the polarized electrode ( 4b) Provide a 200V voltage to form an electric field between the electrodes, and the ions generated in the ionization chamber a...

Embodiment 2

[0021] As shown in Figure 1: high-purity helium (99.9995%) enters the discharge chamber (21) through the discharge gas inlet (1), and the single-chip microcomputer (A) controls the high-voltage power supply (B) to provide stable bidirectional power to the discharge electrodes (3a, 3b) Pulse high voltage, working frequency 20kHz, duty ratio 1:5, pulse width 10μs, period 100μs and pulse amplitude 600V, the distance between the discharge electrodes is 1mm, helium discharges in the discharge chamber to generate plasma, and the sample gas inlet ( 2) The incoming sample gas collides, and the sample gas and high-energy particles are ionized after colliding in the ionization chamber (22), and the single-chip microcomputer (A) controls the DC power supply (C) to plate the gold-plated collecting electrode (4a) on the copper surface, the polarized electrode ( 4b) Provide a 200V voltage to form an electric field between the electrodes, and the ions generated in the ionization chamber are c...

Embodiment 3

[0023] As shown in Figure 1: high-purity helium (99.9995%) enters the discharge chamber (21) through the discharge gas inlet (1), and the single-chip microcomputer (A) controls the high-voltage power supply (B) to provide stable bidirectional power to the discharge electrodes (3a, 3b) Pulse high voltage, working frequency 30kHz, duty ratio 1:4, pulse width 50μs, period 300μs and pulse amplitude 1200V, the distance between the discharge electrodes is 1mm, helium gas discharges in the discharge chamber to generate plasma, and the sample gas inlet ( 2) The incoming sample gas collides, and the sample gas and high-energy particles are ionized after colliding in the ionization chamber (22), and the single-chip microcomputer (A) controls the DC power supply (C) to gold-plate the collecting electrode (4a) on the copper surface, the polarizing electrode ( 4b) Provide 200V voltage to form an electric field between the electrodes, and the ions generated in the ionization chamber are coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amplitude | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com