Water-absorption expanding rubber combination containing montmorillonite absorbent material and preparation method thereof

A technology for water-absorbing swellable rubber and water-absorbing material, applied in the field of high-performance water-absorbing swellable rubber and its preparation, can solve the problems of low water absorption rate and water absorption speed, and achieve the effects of high water absorption rate, low mass loss rate and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation of montmorillonite intercalated composite water-absorbing material A (prepared with reference to the method in CN 03114486.1):

[0035] Add 6.5 mol of acrylic acid and 4.55 mol of sodium hydroxide NaOH to a flask with a stirring device in a cold water bath, then add 4.0 mol of acrylamide and stir thoroughly, then add 0.00525 mol of ethylene glycol diacrylate and 226 g of montmorillonite Finally, add 0.1575 mol of potassium persulfate, gradually raise the temperature to 80°C to initiate polymerization, dry and pulverize to obtain a montmorillonite-sodium acrylate-acrylamide water-absorbing material with a water absorption rate of 17500%.

[0036] Preparation of montmorillonite intercalation composite water-absorbing material B:

[0037] Add 6.0mol of acrylic acid and 3.9mol of NaOH to a flask with a stirring device in a cold water bath, then add 3.5mol of methacrylamide, then add 0.00475mol of ethylene glycol diacrylate and 253 grams of montmorillonite, and f...

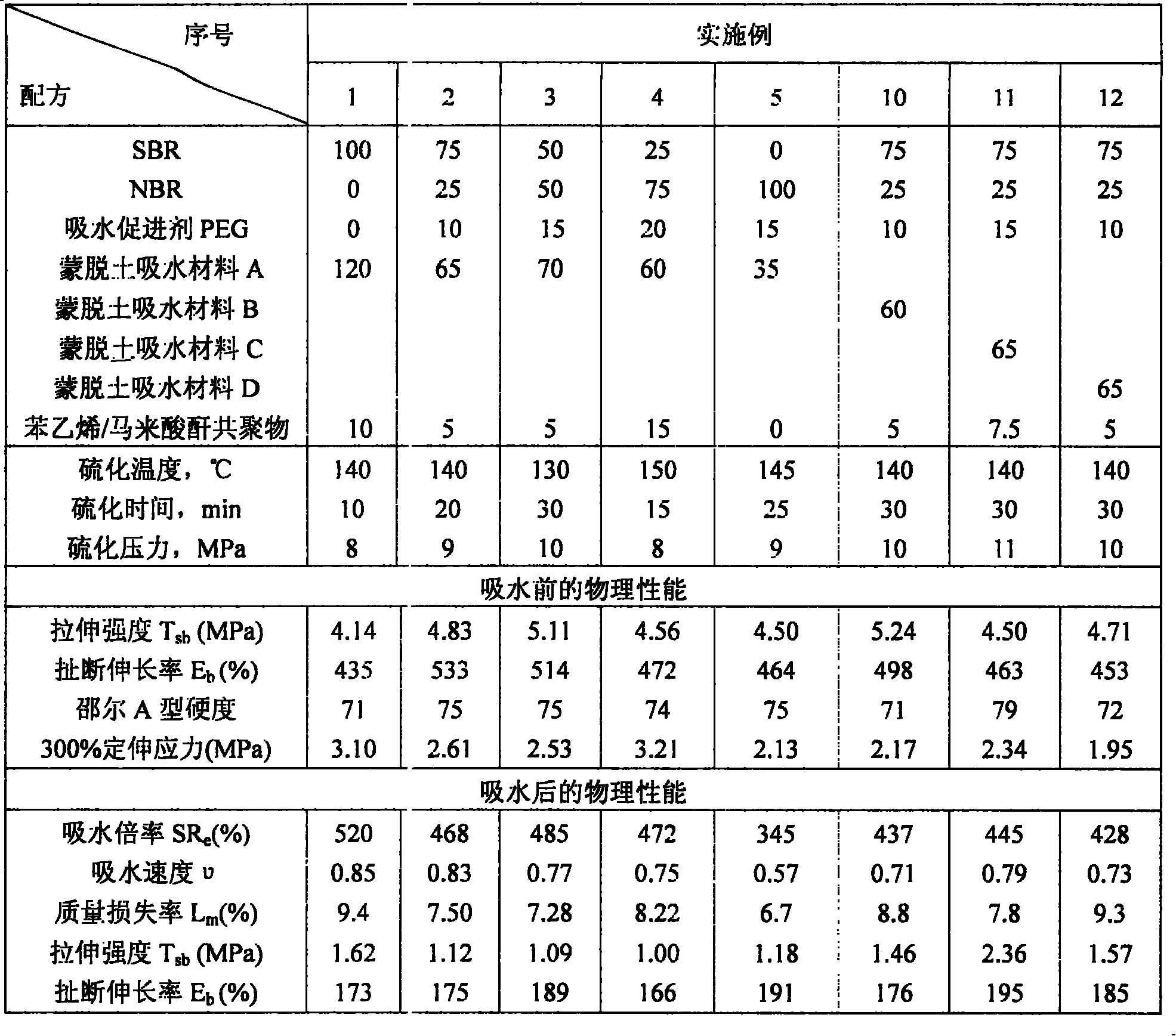

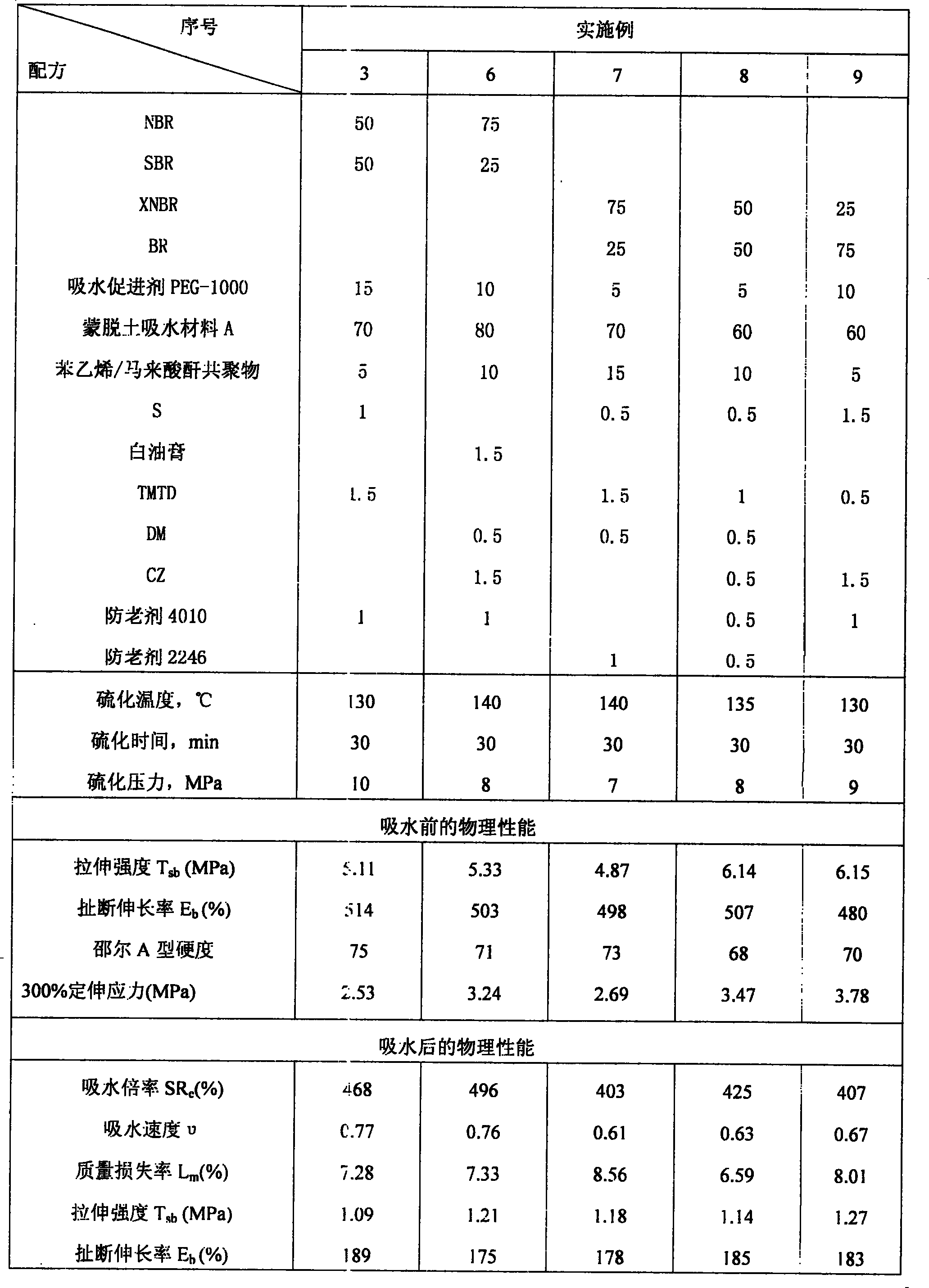

Embodiment 1

[0043] Put 100 parts of SBR / NBR (100 / 0) on the open rubber mixing machine and then add 5 parts of zinc oxide ZnO, 2 parts of SA, 1.5 parts of vulcanization accelerator TMTD, and 1 part of anti-aging agent 4010. , then add 10 parts of compatibilizer styrene / maleic anhydride copolymer, 120 parts of montmorillonite water-absorbing material A, filler (WCB: nano CaCO 3 2 / 8) 40 parts, knead evenly (non-stick roller), finally add 1 part of S, after kneading, make a thin pass, make a triangular bag 6 times, and put the rubber on a flat vulcanizing machine under 8MPa pressure, 140 Vulcanize at ℃ for 10 minutes to obtain a water-swellable rubber composition, referred to as WSR material (hereinafter the same), and its properties are listed in Table 1.

Embodiment 2

[0045] Take 100 parts of base glue SBR / NBR (75 / 25), 65 parts of montmorillonite water-absorbing material A, 10 parts of water absorption accelerator PEG-800, 5 parts of compatibilizer styrene / maleic anhydride copolymer, 5 parts of zinc oxide ZnO, 2 parts of SA, 1.5 parts of vulcanization accelerator TMTD, 1 part of anti-aging agent 4010, filler (WCB: nano CaCO 3 It is 7 / 3) 40 parts, 1 part S, thin pass after kneading evenly, pack into a triangle bag 6 times, take off the sheet, and vulcanize on a flat vulcanizing machine at 9MPa pressure, 140°C for 20min to prepare WSR material, the performance is listed Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com