Silicon oxide mesoporous material and preparing method thereof

A technology of mesoporous material and silica, applied in the field of silica mesoporous material and its preparation, can solve problems such as limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

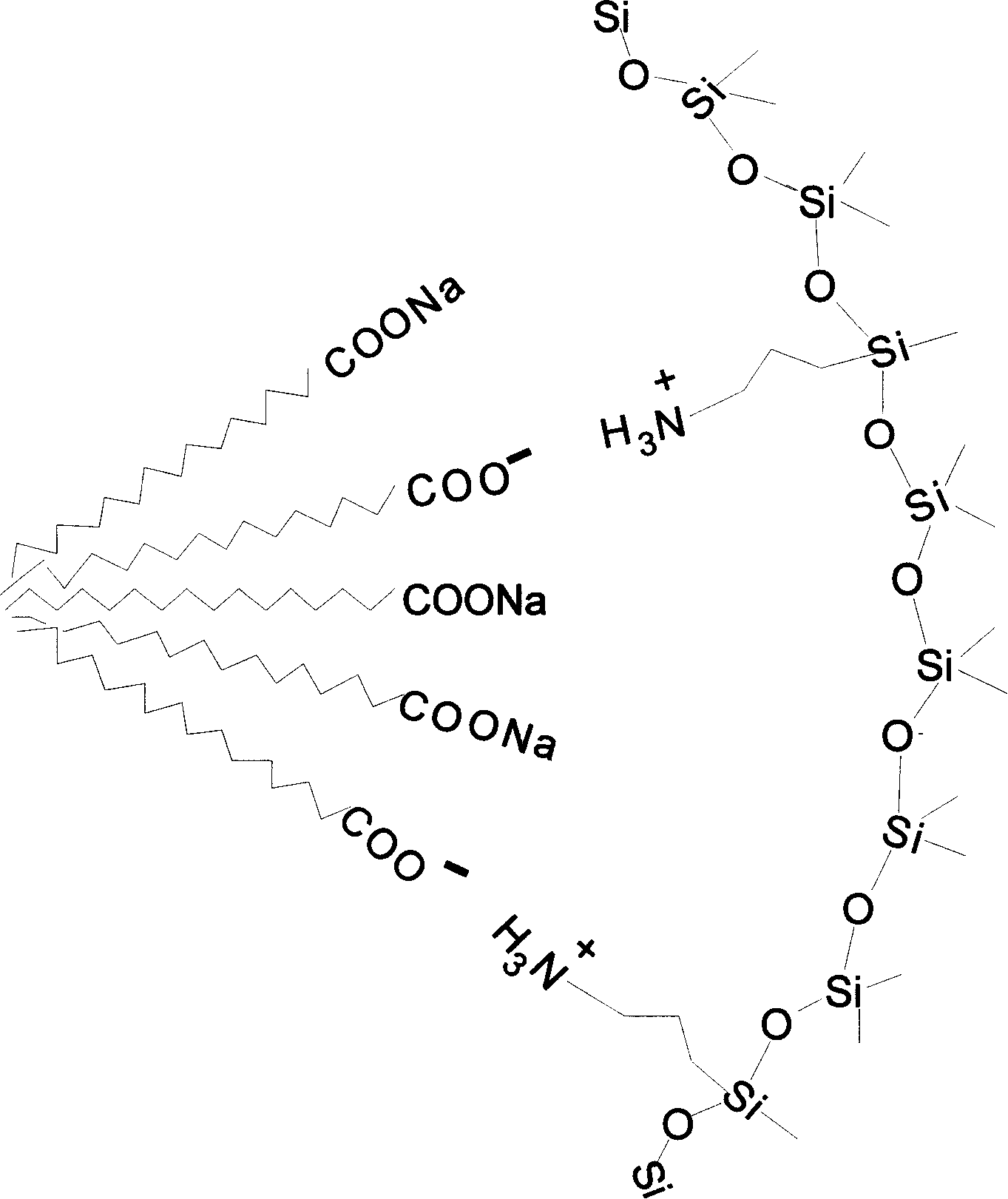

[0035] Embodiment 1 (pure enantiomer spiral streamer morphology silica mesoporous material)

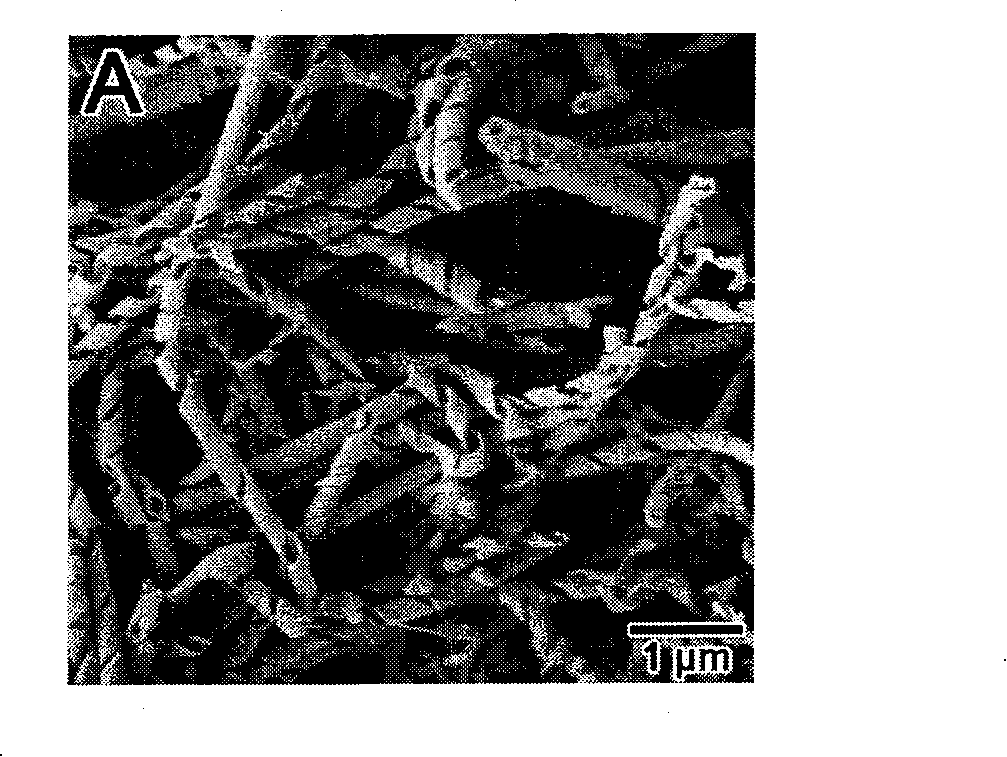

[0036] First add 0.32g (1mmol) C 14 - Dissolve L-AlaS in 22g deionized water, stir at room temperature to dissolve; add 10g (0.1mmol) 0.01M hydrochloric acid solution, stir at room temperature for 20-30 minutes; put it in 0°C and stir for 1-5 hours, Add an alkaline silane with an amino group to help structure-directing agent, then add organosilane into the mixture and stir evenly, then let stand at 0°C for 1-2 days, centrifuge, wash with deionized water, dry at 30°C, and extract to obtain Pure enantiomer spiral ribbon morphology silica mesoporous material, the length of the spiral ribbon is 3-10μm, the diameter is 150-200nm, the pitch is 500-600nm, the mesoporous diameter of the material is 3.6nm, and the pore volume is 600mm 3 g -1 , the specific surface area is 349m 2 g -1 . figure 2 This is the scanning electron microscope picture of this silica mesoporous material, from whic...

Embodiment 2

[0037] Embodiment 2 (hollow spherical shape silica mesoporous material)

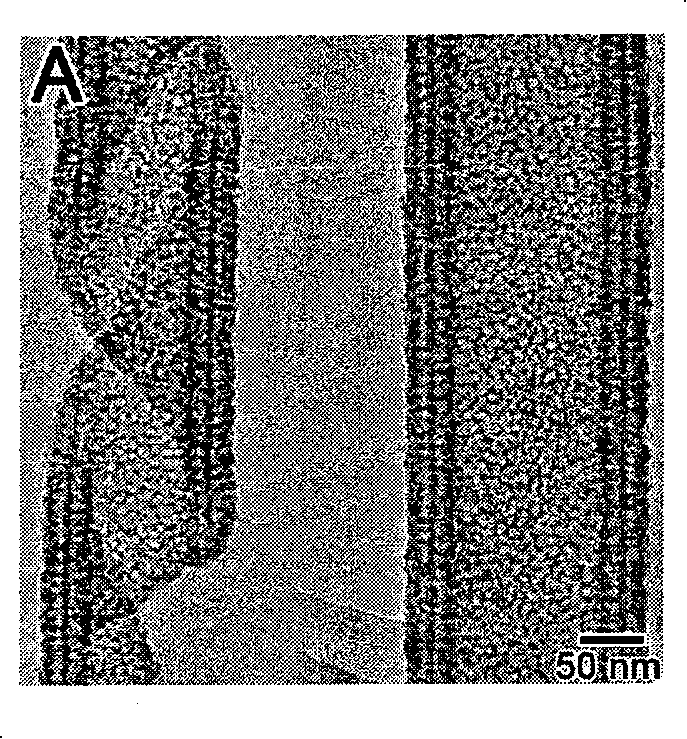

[0038] First add 0.32g (1mmol) C 14 - Dissolve L-AlaS in 22g deionized water, stir at room temperature to dissolve; add 10g (0.1mmol) 0.01M hydrochloric acid solution, stir at room temperature for 20-30 minutes; put it in 10°C and stir for 1-5 hours, Add the basic silane structure-directing agent with amino groups, then add the organosilane into the mixture and stir evenly, then let stand at 10°C for 1-2 days, centrifuge, wash with deionized water, dry at 30°C, and extract to obtain Silica mesoporous material with hollow sphere shape, the diameter of the hollow sphere is 100-400nm, the diameter of the hollow part is 100-150nm, and the thickness of the spherical shell is 50-60nm. The material has a mesopore diameter of 3.6nm and a pore volume of 300-400mm 3 g -1 , the specific surface area is 300-400m 2 g -1 , with a two-dimensional hexagonal p6mm structure. Figure 4 This is the scanning electron m...

Embodiment 3

[0039] Embodiment 3 (pure enantiomer spiral streamer morphology silica mesoporous material)

[0040] First add 0.29g (1mmol) C 14 - Dissolve L-AlaA in 10g deionized water, then add 9g (1mmol) 0.1M sodium hydroxide solution, stir at room temperature to dissolve, then put it at 0°C and stir for 1-5 hours, add the base with amino group Non-toxic silane structure-directing agent, then add organosilane into the mixture and stir evenly, then stand at 0°C for 1-2 days, centrifuge, wash with deionized water, dry at 30°C, and extract to obtain pure enantiomer spiral ribbons Silica mesoporous material, the length of the spiral ribbon is 3-10 μm, the diameter is 150-200nm, and the pitch is 500-600nm. The material has a pore diameter of 3.6nm and a pore volume of 600mm 3 g -1 , the specific surface area is 349m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com