Layered high-entropy MAX-phase ceramic thermoelectric material and preparation method thereof

A technology of thermoelectric materials and high entropy, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of limitations, harsh thermoelectric properties of materials, single material system structure, etc., and achieve layered structure. control, high thermoelectric figure of merit, and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

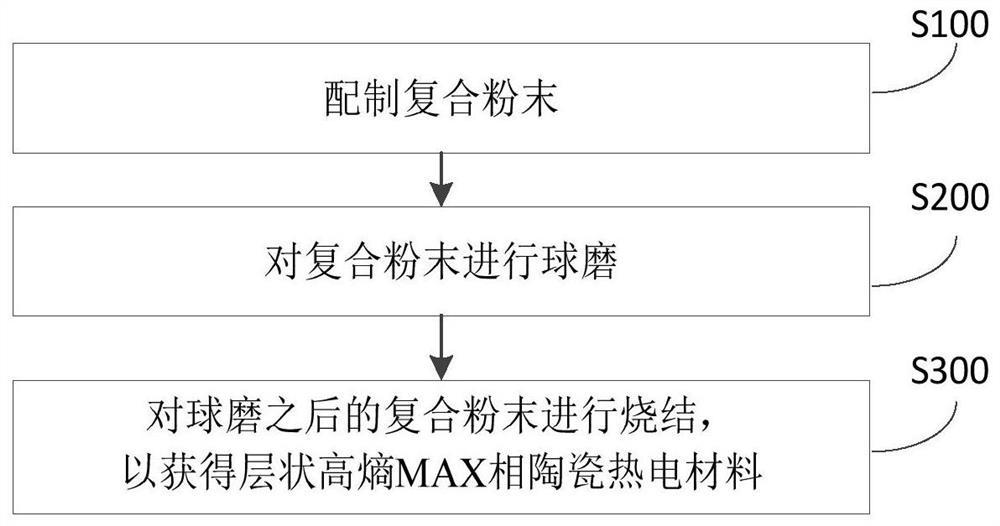

[0038] In another aspect of the present invention, the present invention proposes a method for preparing a layered high-entropy MAX phase ceramic thermoelectric material. According to an embodiment of the present invention, refer to image 3 , the preparation method comprises:

[0039] S100: preparing composite powder.

[0040] In this step, a composite powder is prepared, wherein the composite powder includes M elemental powder, A elemental powder and carbon powder, and the M elemental powder includes at least three elements of group IIIB, IVB, VB and VIB. Specifically, M can be scandium (Sc), titanium (Ti), vanadium (V), chromium (Cr), zirconium (Zr), niobium (Nb), molybdenum (Mo), hafnium (Hf) and tantalum (Ta) At least three elements in A, such as the combination of heavy elements of Cr, V, Ti, Nb and Ta, or the combination of heavy elements of Ti, Nb and Ta; A can be aluminum (Al), silicon (Si), germanium (Ge ), tin (Sn) and sulfur (S) elements at least one element, su...

Embodiment 1

[0053] In this example, a layered high-entropy MAX phase ceramic thermoelectric material was prepared. The specific steps are as follows:

[0054] (1) The M site uses Cr, V, Ti, Nb and Ta as raw materials, and the molar ratio is the same as 0.4, the A site raw material is Al and the X site raw material is C powder, and then according to n(M):n(A) :n(X)=2:1.05:1 ratio to design MAX material composite powder;

[0055] (2) Place the composite powder in a ball mill tank under an argon protective environment for ball milling, the ball milling time is 2 hours, the ball milling speed is 300rmp, after mixing evenly, the composite powder is taken out and sealed for later use;

[0056] (3) The composite powder after ball milling was placed in a SPS sintering furnace in a vacuum environment and reacted at 1300 °C for 5 minutes to obtain a layered high-entropy MAX phase ceramic thermoelectric material.

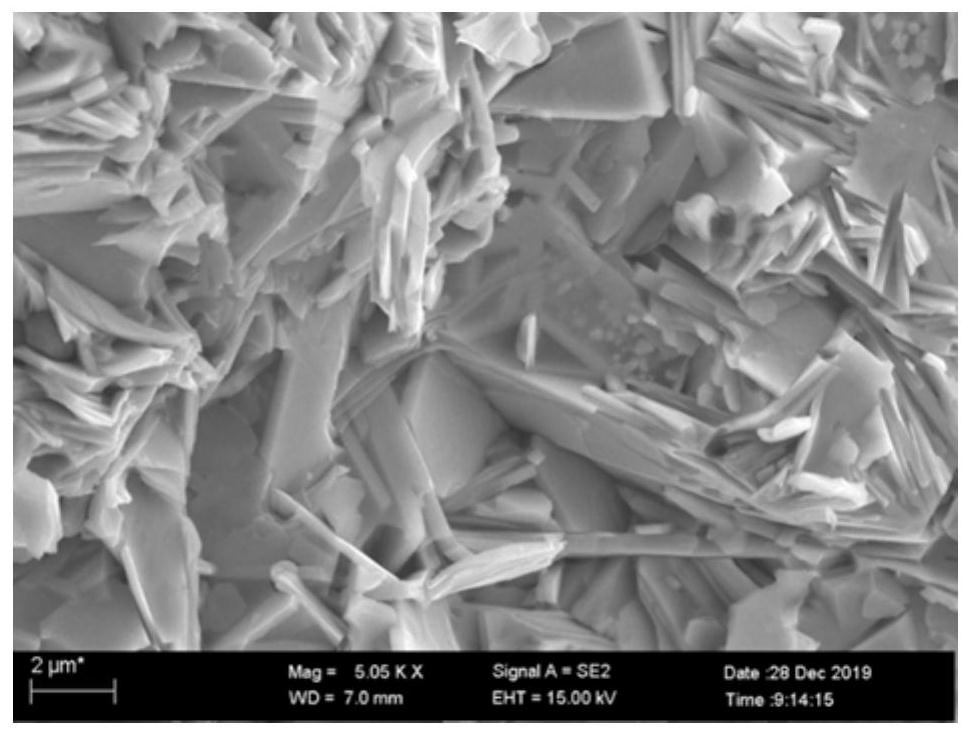

[0057] The layered high-entropy MAX phase ceramic thermoelectric material prepared ...

Embodiment 2

[0061] In this example, the layered high-entropy MAX phase ceramic thermoelectric material was prepared according to the same method and conditions as in Example 1. In this example, the differences are: (1) the M site uses Ti, Nb and Ta as raw materials, and the molar ratio is the same as 0.67; (2) the ball milling time is 3 hours, and the ball milling speed is 200rmp; (3) sintering at 1300°C React for 10 minutes.

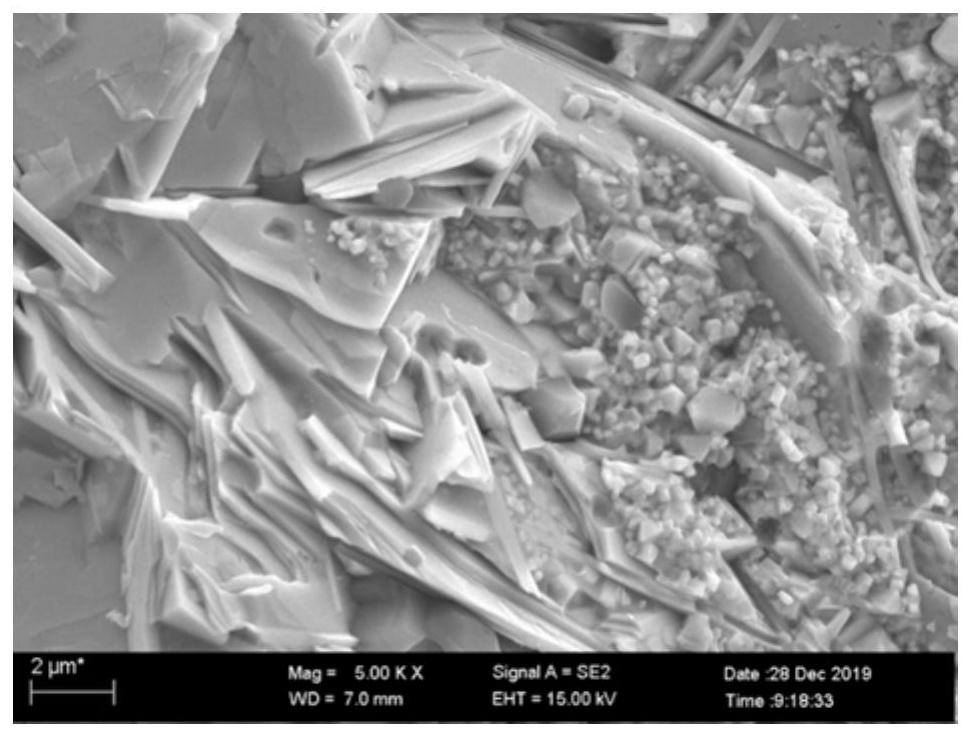

[0062] The layered high-entropy MAX phase ceramic thermoelectric material prepared in this embodiment, its SEM photo reference figure 2 . Then, the ceramic thermoelectric material was made into a sample with a diameter of 16mm and a thickness of 2.93mm, and the thermal conductivity test was performed, and the thermal conductivity of the layered high-entropy MAX phase ceramic thermoelectric material at room temperature was 11.35W m -1 K -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com