Crystallization-amorphism-crystallization stereo triblock polybutadiene and preparation method thereof

A technology of polybutadiene and polybutadiene block, applied in the field of polymer material synthesis and preparation, to achieve the effect of promoting characterization research work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] In a 5-liter stainless steel reactor with stirring, add 3.5 liters of cyclohexane and 350 grams of butadiene, raise the temperature to 60°C, and add the bifunctional alkyllithium initiator 1,1'-(1,3-phenylene )-bis[3-methyl-1-(4-methylphenyl)pentyl]dilithium, start to prepare LCBR block, the amount of alkyllithium is 8×10 according to the polymer number average molecular weight 4 Metering, when the butadiene polymerization conversion rate reaches 50%, add barium thymol (BAT) and triisobutyl aluminum, start to prepare HTBR block, barium thymol (BAT) consumption is 0.5mmolBa / 100gBd ( butadiene), the amount of triisobutylaluminum is measured as (molar ratio) 1.0 / 4.0 / 4.0 according to the Ba / Al / Li ratio, and the reaction is continued until all butadiene is polymerized. After the butadiene polymerization is all finished, add Antiaging agent (1010 and 2.6.4 are mixed with weight ratio 1: 1) 3.5 grams, adopt traditional method to carry out glue solution aftertreatment, obtain H...

Embodiment 2

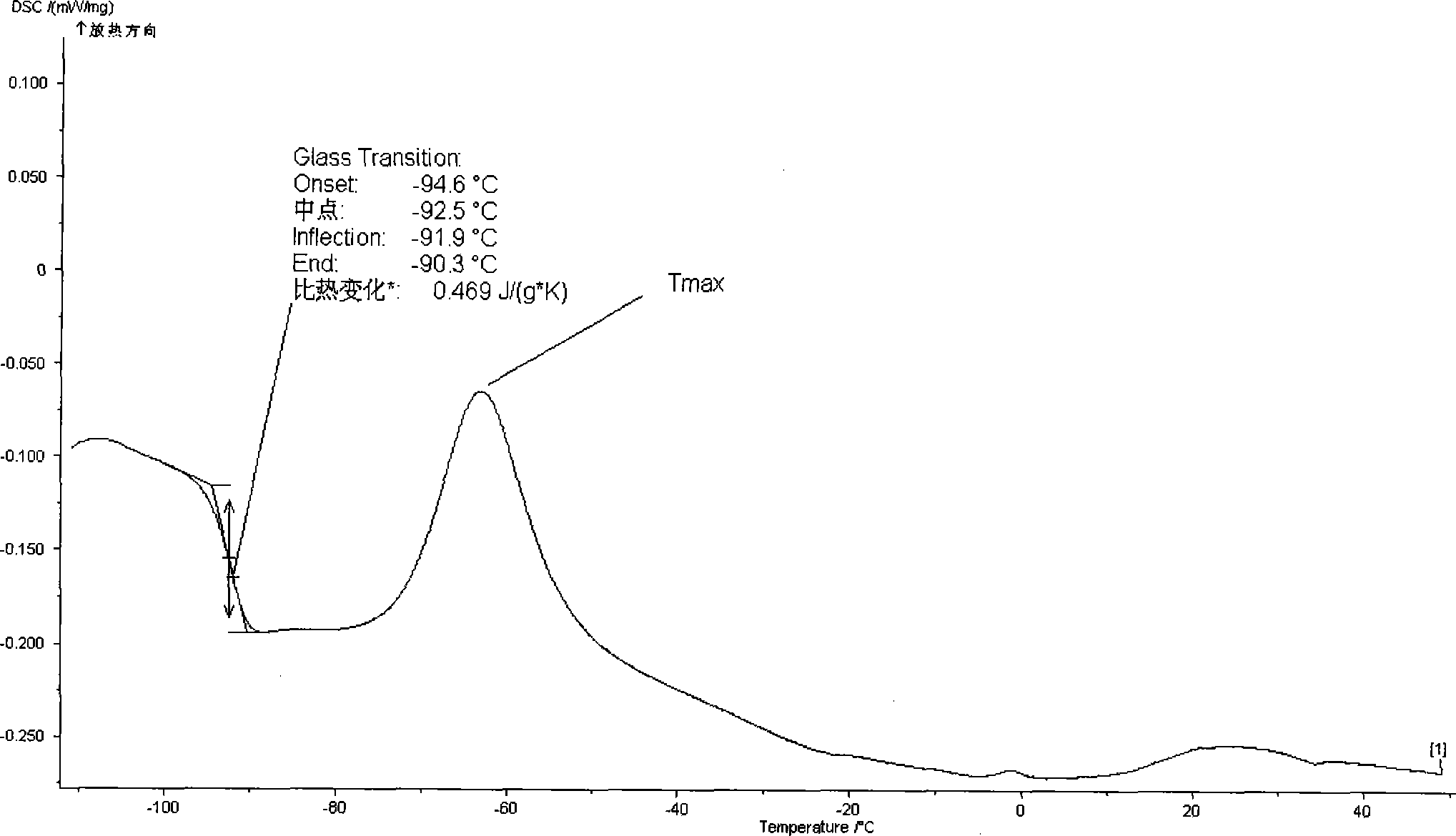

[0021] When the conversion rate of butadiene polymerization reaction reached 70%, barium thymol (BAT) and triisobutylaluminum were added, and other preparation conditions were exactly the same as in Example 1, and the prepared HTBR-LCBR-HTBR stereoterene The block ratio of segmented polybutadiene is 15 / 70 / 15, and its structure and performance analysis results are as follows: the total content of trans 1,4-structure in stereotriblock polybutadiene is 57.5%, and in HTBR block The trans 1,4-structure content is 77.0%, the molecular weight distribution index is 1.30, the glass transition temperature is -92.1°C, and the crystallization temperature is -65.8°C.

Embodiment 3

[0023] When the conversion rate of butadiene polymerization reaction reached 30%, barium thymol (BAT) and triisobutylaluminum were added, and other preparation conditions were exactly the same as in Example 1, and the prepared HTBR-LCBR-HTBR stereoterene The block ratio of block polybutadiene is 35 / 30 / 35, and its structural and performance analysis results are as follows: the total content of trans 1,4-structure in stereo triblock polybutadiene is 67.5%, and in HTBR block The trans 1,4-structure content is 77.0%, the molecular weight distribution index is 1.38, the glass transition temperature is -91.4°C, and the crystallization temperature is -64.1°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com