Environment-friendly type insulated dope for cold rolling non-oriented silicon steel and preparation method for coat thereof

A technology of insulating paint and oriented silicon steel, applied in epoxy resin paint, coating and other directions, can solve the problems of reduced corrosion resistance of insulating film, reduced performance of insulating film, inability to meet processing technology, etc., to achieve bright surface and improve stability performance, good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

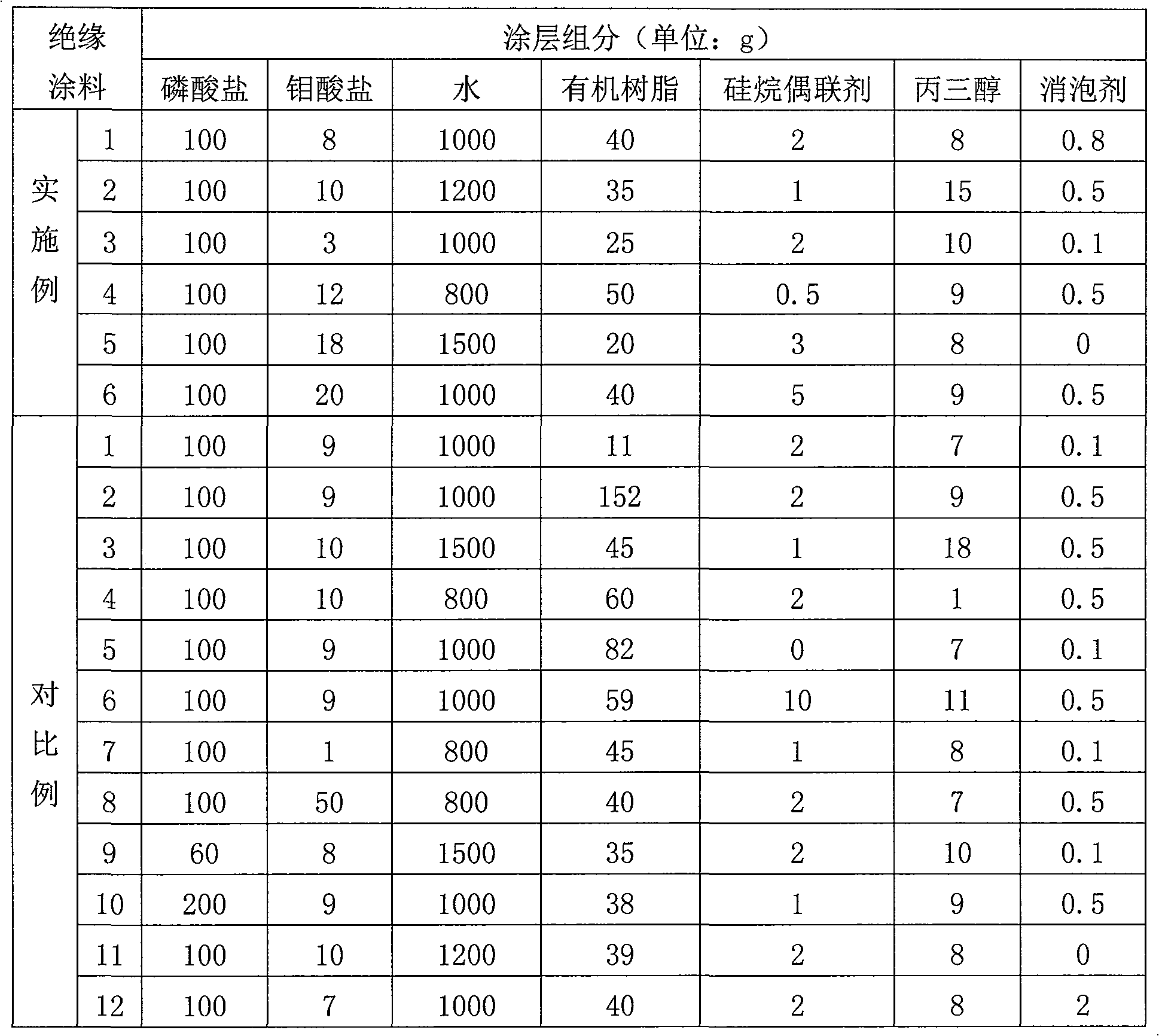

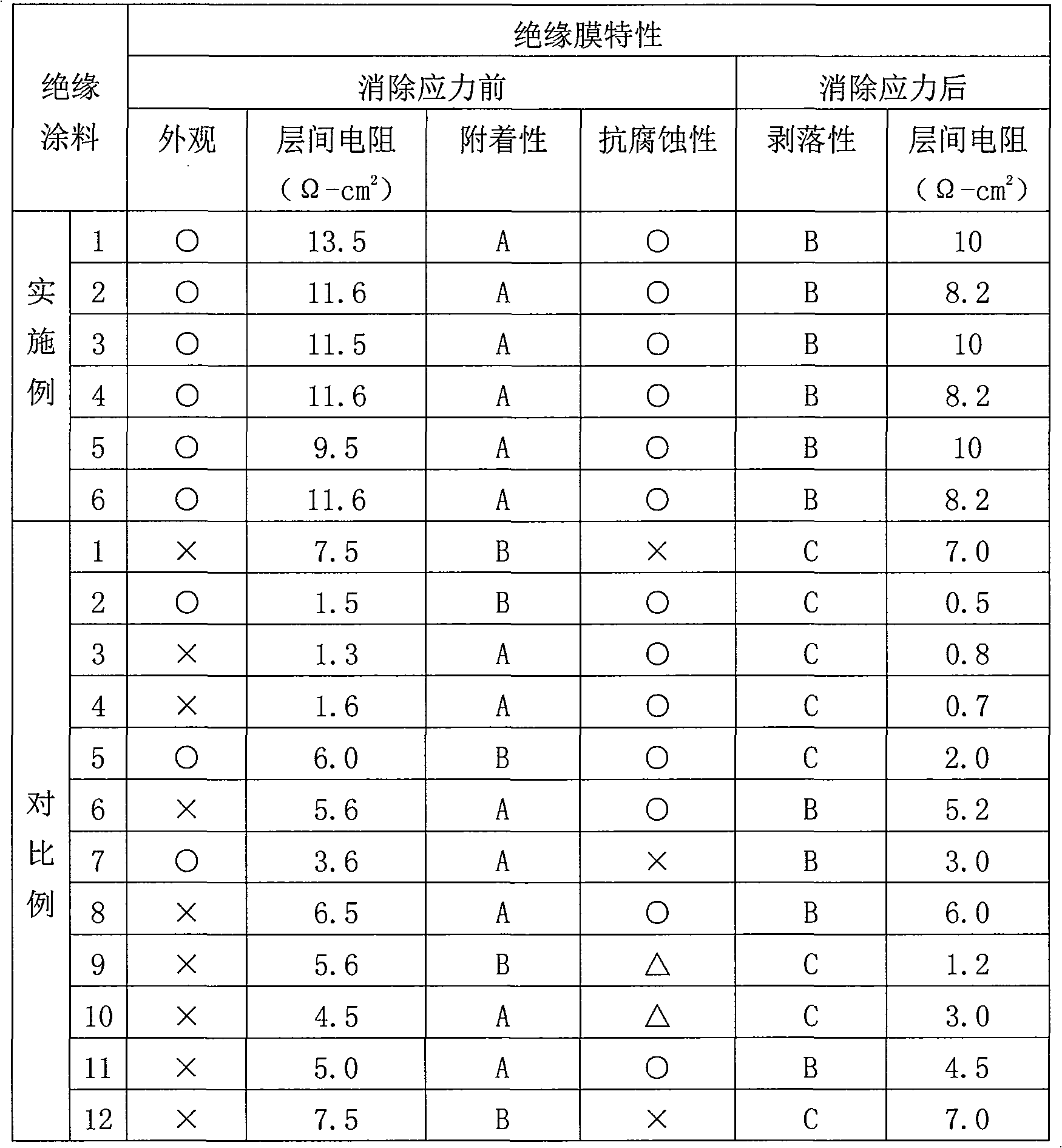

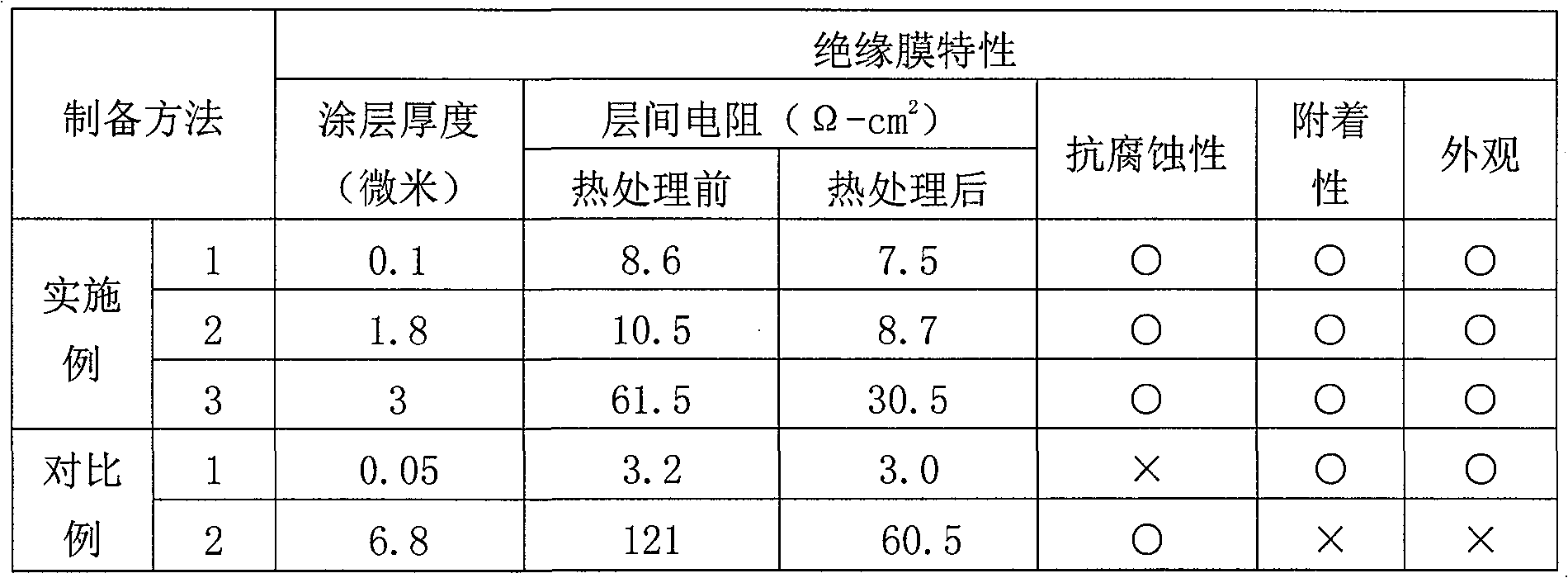

Examples

Embodiment 1

[0042] The phosphate in Example 1 is a mixture of magnesium phosphate and aluminum phosphate; the molybdate is sodium molybdate; the organic resin is an acrylic-styrene resin emulsion.

Embodiment 2

[0043] The phosphate of embodiment 2 is magnesium phosphate; Molybdate is the mixture of sodium molybdate, lithium molybdate; Organic resin is epoxy resin.

Embodiment 3

[0044] The phosphate in embodiment 3 is a mixture of magnesium phosphate, aluminum phosphate, calcium phosphate and zinc phosphate; the molybdate is lithium molybdate; the organic resin is a fluorocarbon resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com