A white light organic EL part consisting of RGB and its making method

An electroluminescent device and organic technology, applied in electroluminescent light sources, chemical instruments and methods, electrical components and other directions, can solve the problems of complex process, difficulty in improving resolution, difficulty in precise alignment, etc., and achieve a reasonable and simple preparation method. , fast response, wide viewing angle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

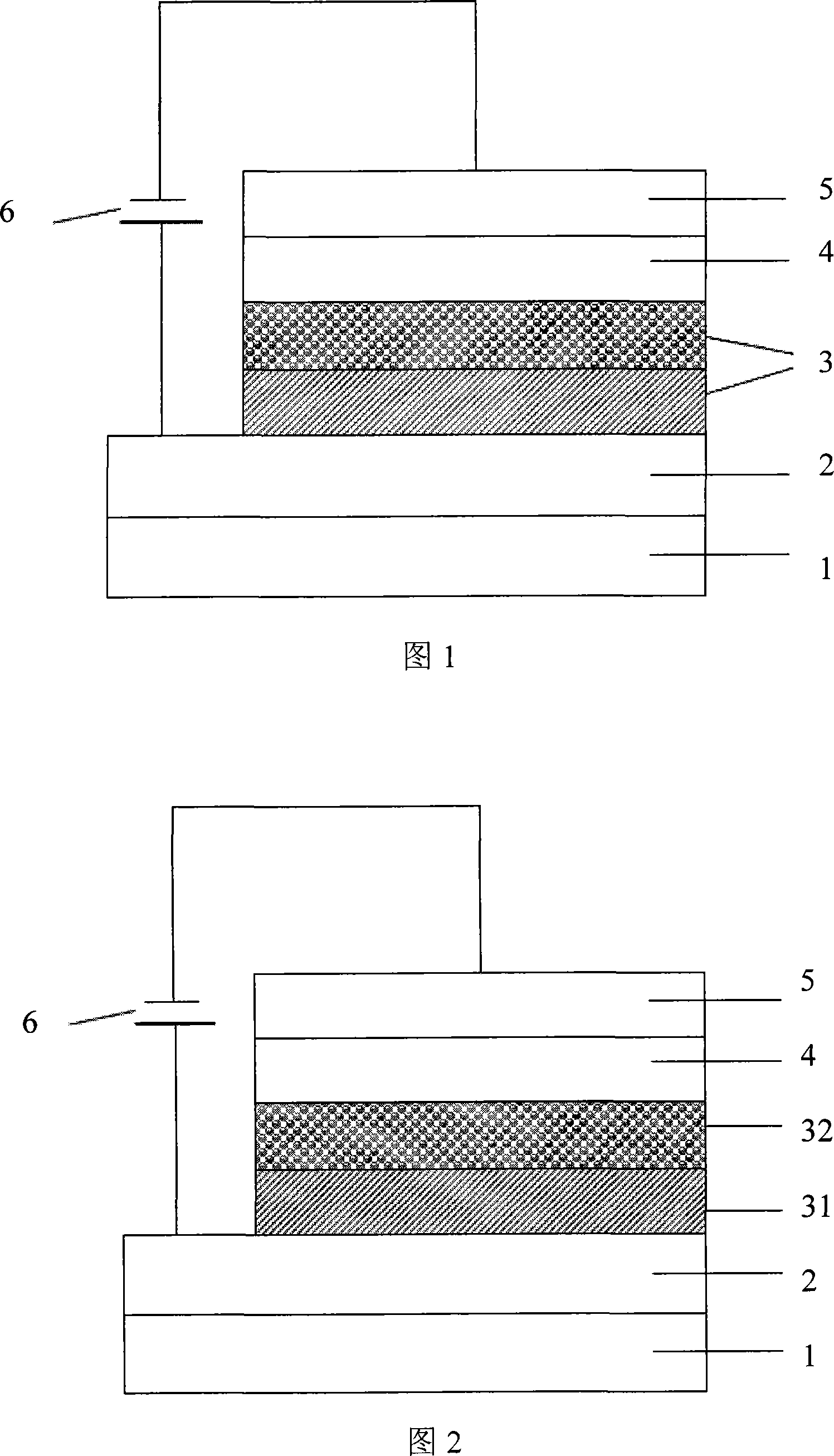

[0089] As shown in FIG. 2 , the light emitting layer 3 in the structure of the device includes a hole transport layer also serving as a blue light emitting layer 31 , a green light emitting layer also serving as a red light emitting layer 32 , and a hole blocking layer also serving as an electron transport layer 4 .

[0090] The fluorescent material emitting blue light of the device is NPB, the fluorescent material emitting green light and the phosphorescent dye emitting red light are Alq 3 :(nazo) 2 Ir(Fppz), the hole blocking layer doubles as the electron transport material BCP, and the cathode layer uses Mg:Ag alloy. The entire device structure is described as:

[0091] Glass substrate / ITO / NPB(50nm) / Alq 3 :(nazo) 2 Ir(Fppz)(40nm) / BCP(20nm) / Mg:Ag(100nm)

[0092] The preparation method is as follows:

[0093] ①Use detergent, ethanol solution and deionized water to ultrasonically clean the transparent conductive substrate ITO glass, and dry it with dry nitrogen after clea...

Embodiment 2

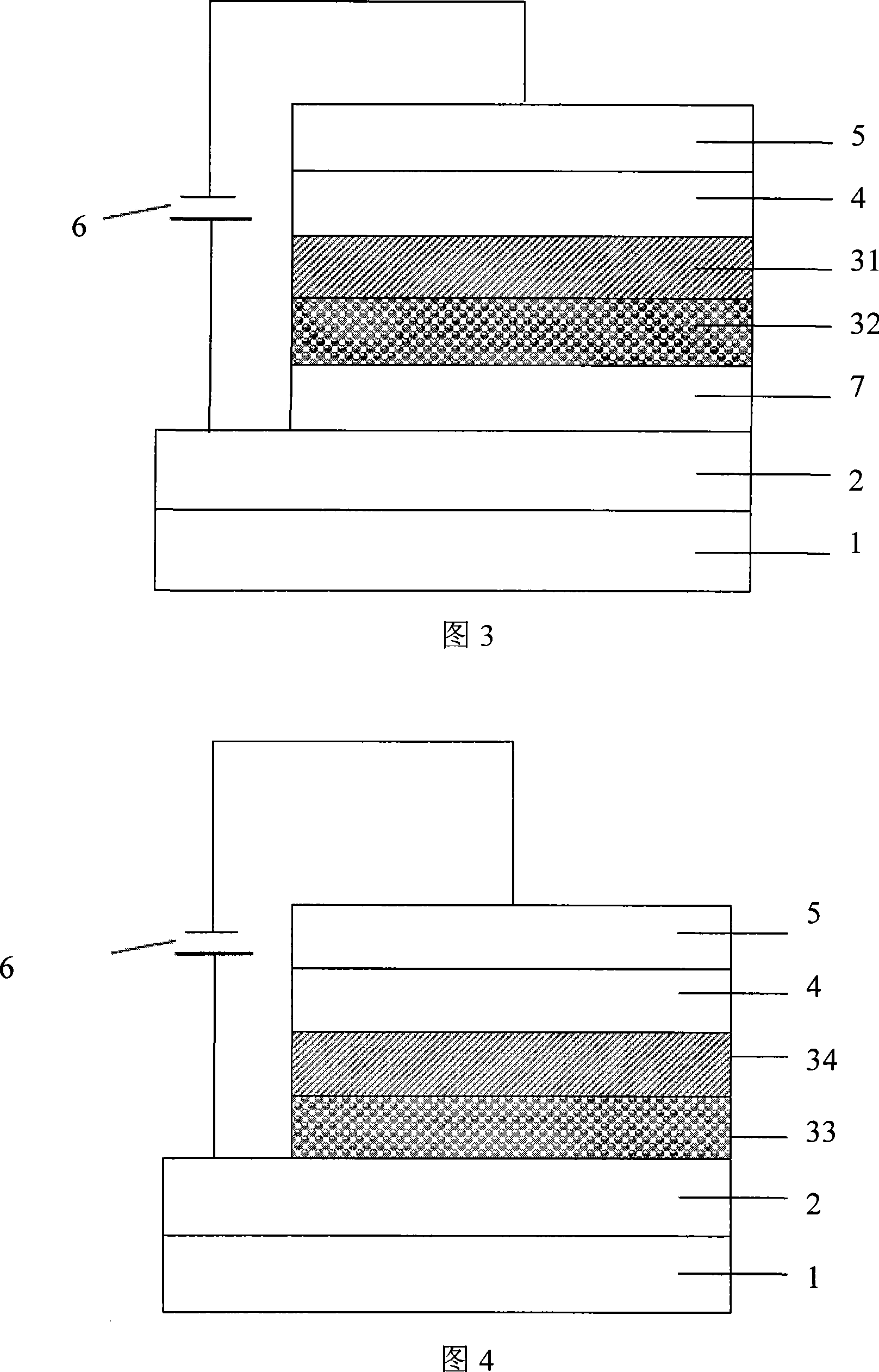

[0100] As shown in Figure 3, the light emitting layer 3 in the structure of the device includes a hole transport layer 7, the hole transport layer doubles as a blue light emitting layer 31, the green light emitting layer doubles as a red light emitting layer 32, and the hole blocking layer doubles as an electron transport layer 4.

[0101] The fluorescent material emitting blue light of the device is NPB, the fluorescent material emitting green light and the phosphorescent dye emitting red light are Alq 3 :(nazo) 2 Ir(Fppz), the hole transport layer material is NPB, the hole blocking layer doubles as the electron transport material BCP, and the cathode layer uses Mg:Ag alloy. The entire device structure is described as:

[0102] Glass substrate / ITO / NPB(40nm) / Alq 3 :(nazo) 2 Ir(Fppz)(40nm) / NPB(10nm) / BCP(20nm) / Mg:Ag(100nm)

[0103] The fabrication process of the device is similar to that of Example 1.

Embodiment 3

[0105] As shown in FIG. 4 , the light-emitting layer 3 in the structure of the device includes a hole-transport layer that doubles as a blue light-emitting layer and a red light-emitting layer 33 , a green light-emitting layer 34 , and a hole-blocking layer that doubles as an electron-transport layer 4 .

[0106] The fluorescent material emitting blue light and the phosphorescent dye emitting red light of the device are NPB: (nazo) 2 Ir(Fppz), the fluorescent material that emits green light is Alq 3 , The hole blocking layer doubles as the electron transport material BCP, and the cathode layer uses Mg:Ag alloy. The entire device structure is described as:

[0107] Glass substrate / ITO / NPB:(nazo) 2 Ir(Fppz)(50nm) / Alq 3 (40nm) / BCP(20nm) / Mg:Ag(100nm)

[0108] The fabrication process of the device is similar to that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com