Special fertilizer for desert and desertification treatment and preparation method thereof

A special fertilizer, desert technology, applied in the application, nitrogen fertilizer, potash fertilizer and other directions, can solve the problem of difficult sand fixation, and achieve the effects of low price, low production cost, and easy popularization and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The special fertilizer for desert and desertification control is composed of the following raw materials in weight percentage: 69% of weathered lignite, 23% of ammonium bicarbonate, 5% of monoammonium phosphate, and 3% of potassium sulfate.

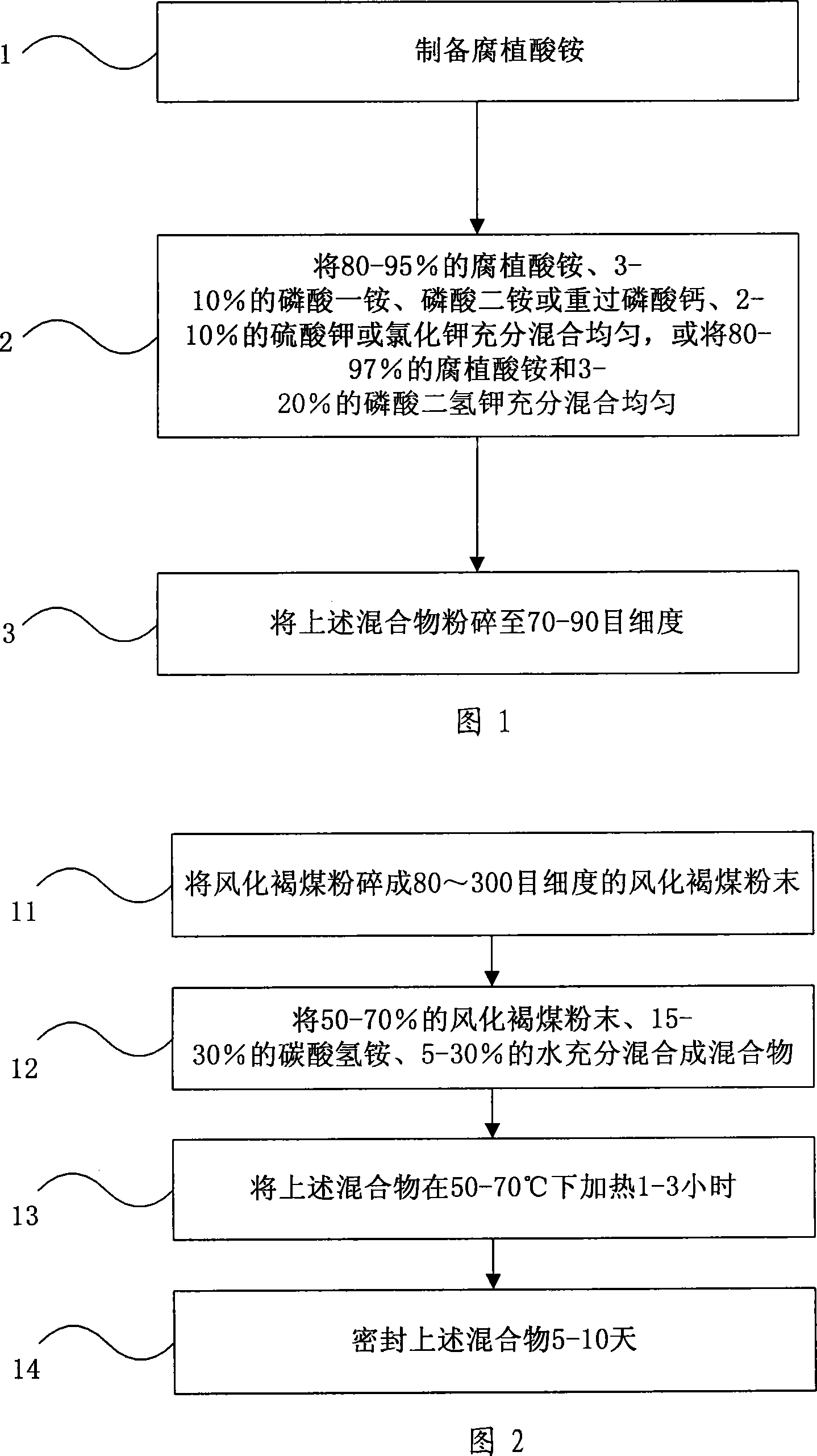

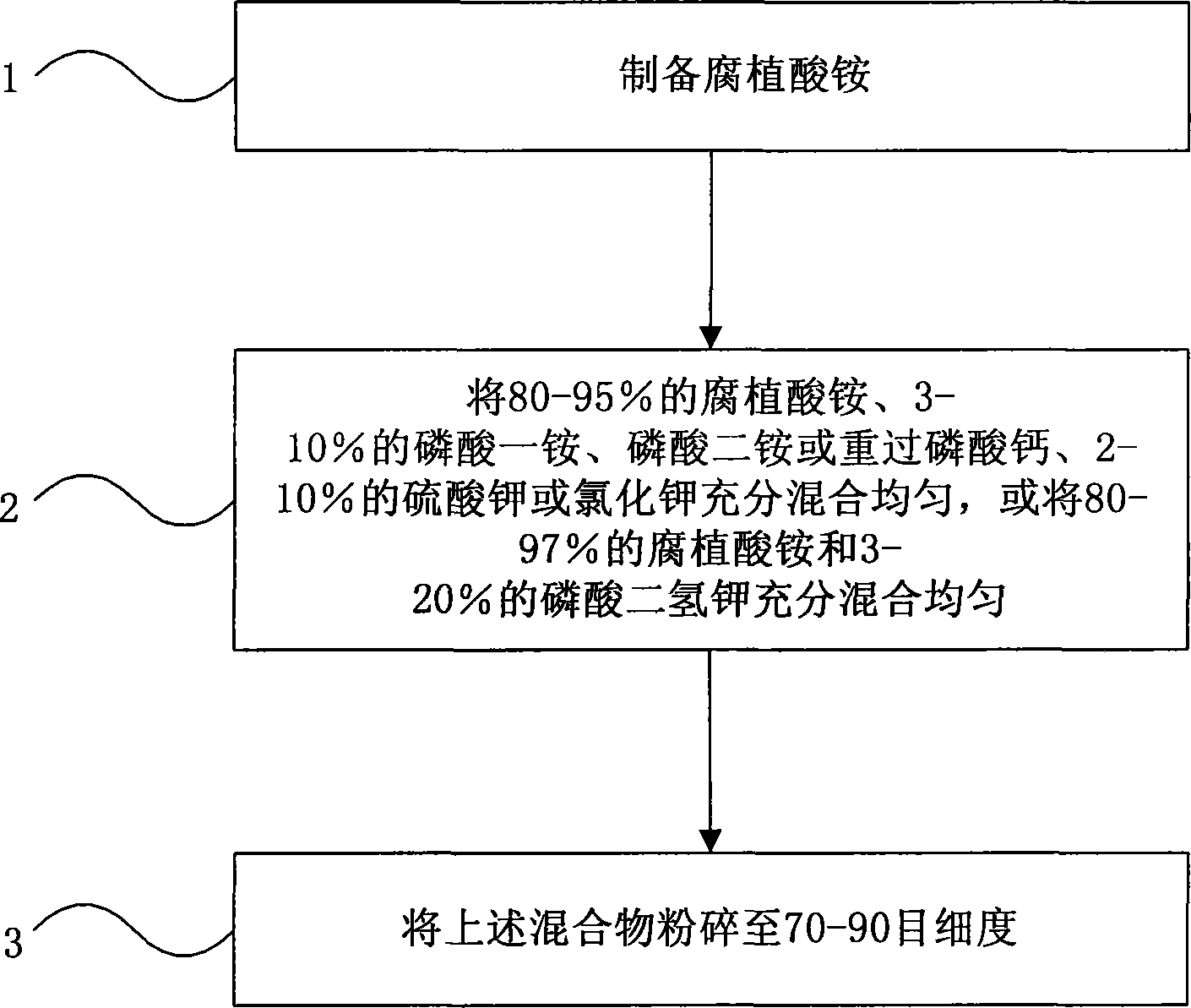

[0042] Embodiment 1 The special fertilizer for desert and desertification control is made according to the following preparation method: first, the weathered lignite is pulverized to the weathered lignite powder that can pass through a 120 mesh sieve fineness, and then the weathered lignite powder: ammonium bicarbonate=69: 23% by weight and water, stir and mix evenly, heat at 60°C for 2 hours after fully mixing, and then seal for 7 days to form ammonium humate; then dry ammonium humate at 65°C for 2 hours to make it contain The water content is less than 10%, and finally mixed with 5% monoammonium phosphate and 3% potassium sulfate by weight, and the mixture is crushed by a pulverizer to a fineness that can pass through an 80-mesh s...

Embodiment 2

[0044] The special fertilizer for desert and desertification control is composed of the following raw materials in weight percentage: 50% of weathered lignite, 30% of ammonium bicarbonate, 10% of diammonium phosphate, and 10% of potassium sulfate.

[0045] Embodiment 2 The special fertilizer for desert and desertification control is made according to the following preparation method: first, the weathered lignite is pulverized to the weathered lignite powder that can pass through a 300 mesh sieve fineness with a pulverizer, and then the weathered lignite powder: ammonium bicarbonate=50: 30% by weight and water, stir and mix evenly, mix thoroughly, heat at 50°C for 3 hours, and then seal for 10 days to form ammonium humate; then dry ammonium humate at 80°C for 1 hour to make it contain The amount of water is less than 10%, and finally mixed with 10% by weight of diammonium phosphate and 10% of potassium sulfate, and the mixture is crushed by a pulverizer to a fineness that can pa...

Embodiment 3

[0047] The special fertilizer for desert and desertification control is composed of the following raw materials in weight percentage: 70% of weathered lignite, 15% of ammonium bicarbonate, 8% of monoammonium phosphate, and 7% of potassium chloride.

[0048] Embodiment 3 The special fertilizer for desert and desertification control is made according to the following preparation method: first, the weathered lignite is pulverized to the weathered lignite powder that can pass through the fineness of 80 mesh sieves with a pulverizer, and then the weathered lignite powder: ammonium bicarbonate=70: 15% by weight and stir to mix evenly, mix thoroughly and heat at 70°C for 1 hour, then seal for 5 days to form ammonium humate; then dry ammonium humate at 50°C for 3 hours to make the water content It is less than 15%, and finally mixed with 8% monoammonium phosphate and 7% potassium chloride by weight, and the mixture is crushed by a pulverizer to a fineness that can pass through a 70-mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com