Method for processing sewage in non-clogging highly effective vertical subsurface flow wetland

A sewage treatment method and vertical subsurface flow technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of poor treatment effect and easy blockage, and achieve cost reduction, Reduce the difficulty and cost of construction and increase the effect of reoxygenation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

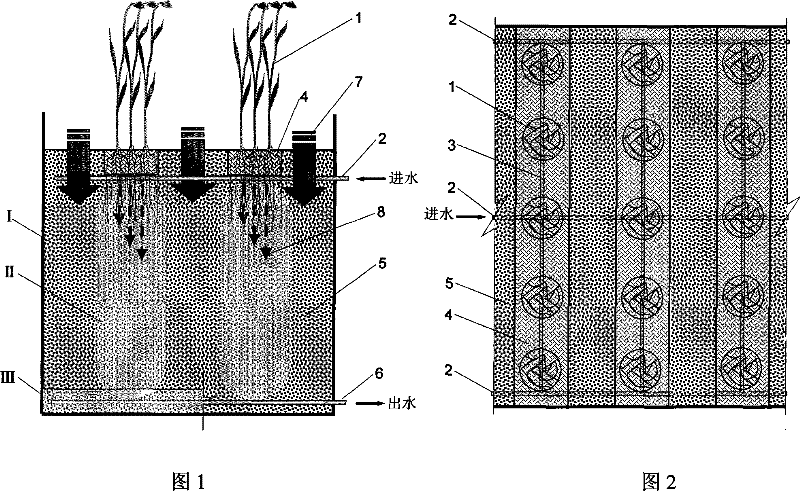

[0027] The present invention is further described below by way of examples. like figure 1 It is a structural diagram of the present invention and Fig. 2 is figure 1 The top view shows:

[0028] The non-clogging high-efficiency vertical subsurface flow artificial wetland proposed by the present invention is composed of wetland plants 1, water distribution main pipe 2, water distribution branch pipe 3, fine-grained substrate 4, medium-grained substrate 5 and water-collecting main pipe 6, wherein , the fine-grained matrix 4 is arranged in a long strip along the direction of the water distribution branch pipe 3, and the space between each strip-shaped fine-grained matrix 4 is filled with the medium-grained matrix 5 until the surface is flush; the water distribution main pipe 2 and the branch pipe 3 Located below the bottom of the matrix 4, the main water collection pipe 6 is located at the bottom of the medium particle size matrix 5, the surface of the fine particle size matrix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com