Method for preparing N-dimethylamino propyl methyl acrylamide

A dimethylaminopropyl methacrylamide, catalytic cracking technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylic acid amides, etc., can solve problems affecting product quality, blockage of reaction equipment, production and operation difficulties, etc. problems, to achieve the effect of less three wastes, less by-products and less polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

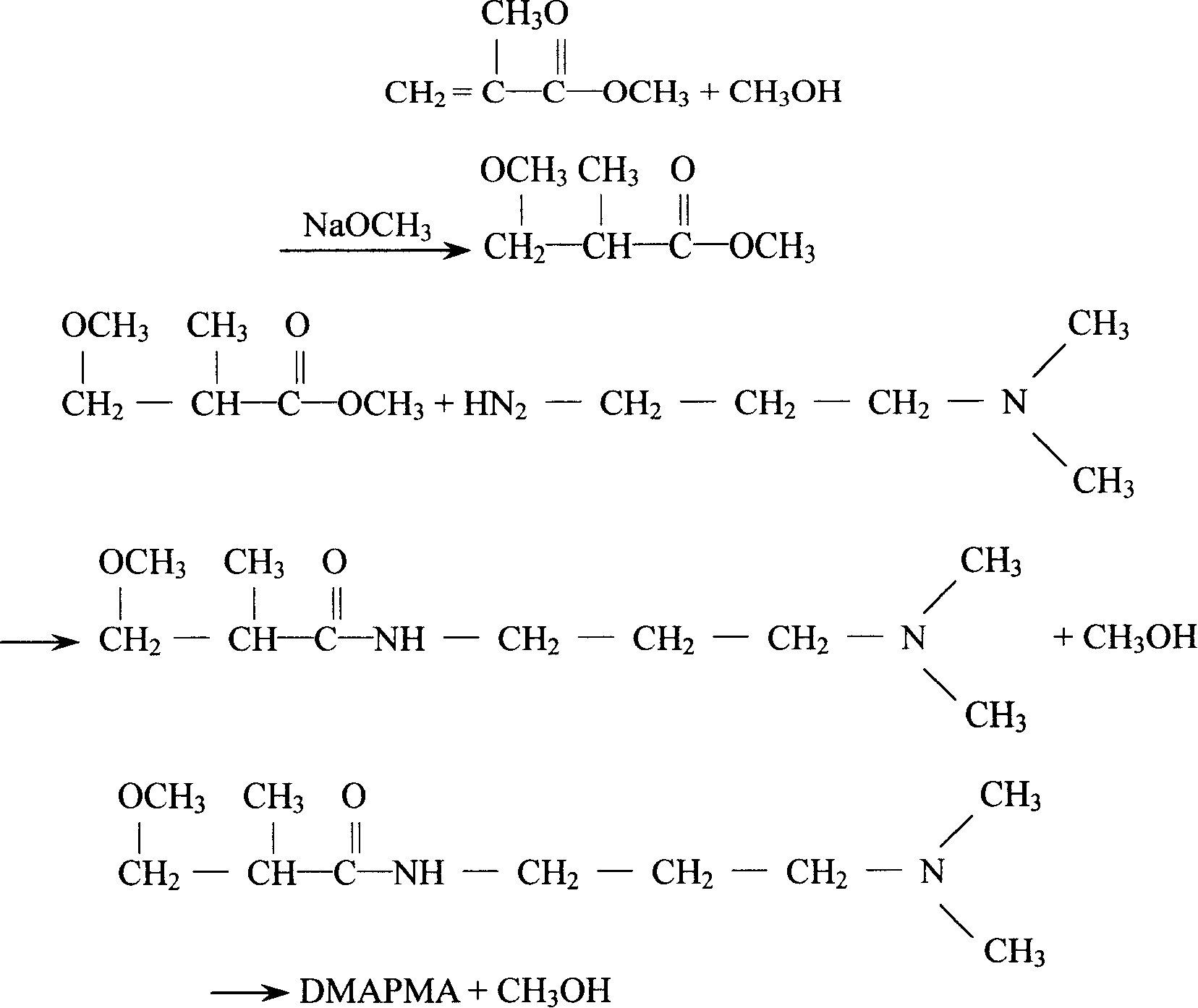

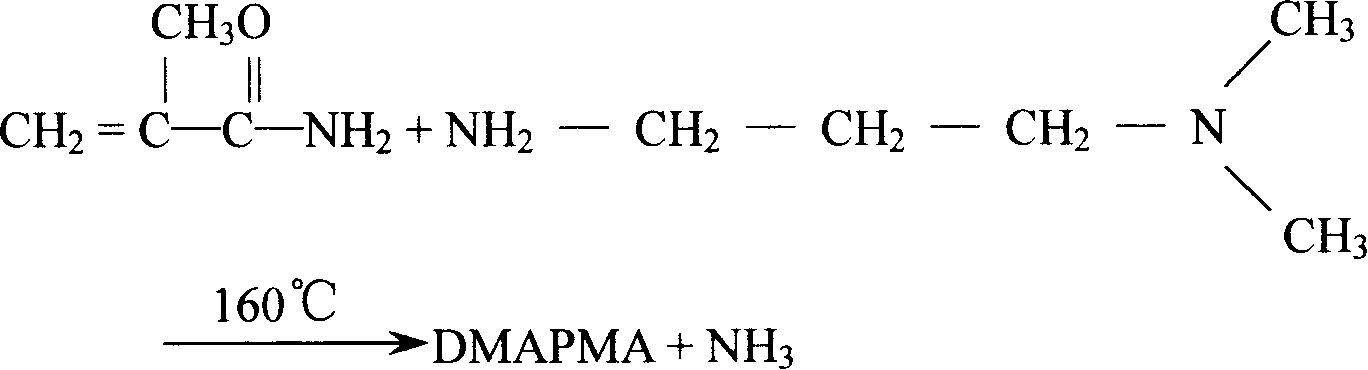

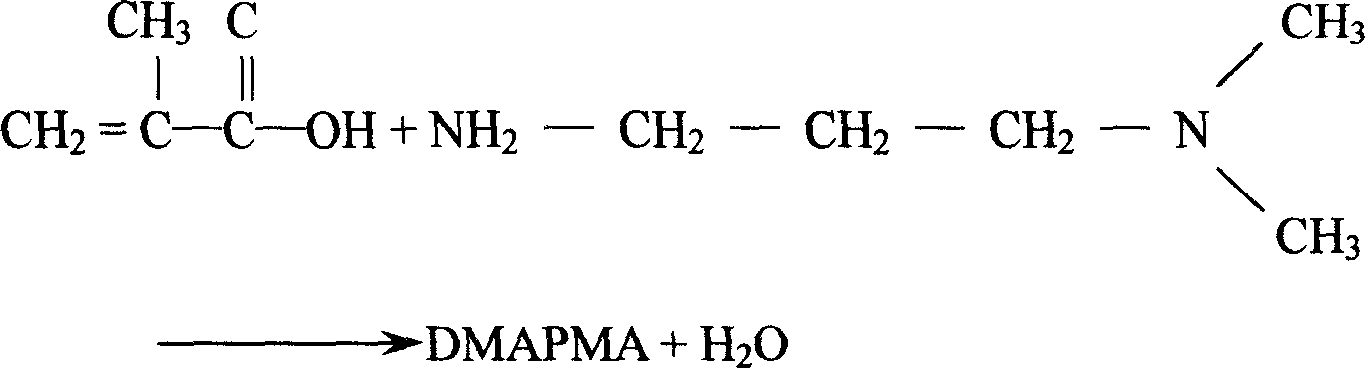

Method used

Image

Examples

Embodiment 1

[0037] step 1:

[0038] 100 grams of methyl methacrylate, 300 grams of N,N-dimethyl-1,3-propanediamine were added into the reaction kettle, and 8 grams of carbon dioxide were introduced into the reactor, stirred and heated to 100°C for 6 hours, then cooled and evaporated under reduced pressure. Excessive N, N-dimethyl-1,3-propanediamine is the intermediate product N-dimethylaminopropyl-β-dipropylaminomethacrylamide.

[0039] Step 2:

[0040] 1 g Ca(NO 3 ) 2 4H 2 0, 18 grams of above-mentioned intermediate products are added in the reaction flask that has vacuum distillation unit, decompression is to 10mmHg, when stirring is warming up to 220 ℃, raw material and product are distilled out, intermediate product and Ca(NO 3 ) 2 4H 2O was slowly dripped into the reaction flask, and the cracked products and raw materials were also distilled out during the dropping process. After 5 hours, the reaction was completed, and the distillate contained 31.1% of the raw material N,N-di...

Embodiment 2

[0044] step 1:

[0045] Pass 20 grams of carbon dioxide into the reactor, stir and heat up to 90°C for 7 hours, and the others are the same as in Example 1;

[0046] Step 2:

[0047] 0.9 g Ca(NO 3 ) 2 4H 2 0, 18 gram intermediate products add in the reaction bottle that has vacuum distillation unit, stir and be warming up to 240 ℃, other are with embodiment one;

[0048] Step 3:

[0049] 1.3 gram of p-hydroxyanisole is added in the reaction bottle of rectification tower, other is the same as embodiment one.

Embodiment 3

[0051] step 1:

[0052] Feed 14 grams of carbon dioxide into the reactor, stir and heat up to 96°C for 6.5 hours, and the others are the same as in Example 1;

[0053] Step 2:

[0054] 0.95 g Ca(NO 3 ) 2 4H 2 0, 18 gram intermediate products add in the reaction flask that has vacuum distillation unit, stir and be warming up to 230 ℃, other are with embodiment one;

[0055] Step 3:

[0056] 1 gram of p-hydroxyanisole is added in the reaction flask of the rectifying tower, and the others are the same as in Example 1.

[0057] As a result of implementation, the total yield can reach 70%, and the product content is 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com