Quantitative reduction method for biological sludge

A biological sludge and sludge technology, applied in biological sludge treatment, sludge treatment and other directions, can solve the problems of high energy consumption, difficulty in breaking the microbial cell wall, and high cost, saving alkali consumption and reducing the cost of wall breaking. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

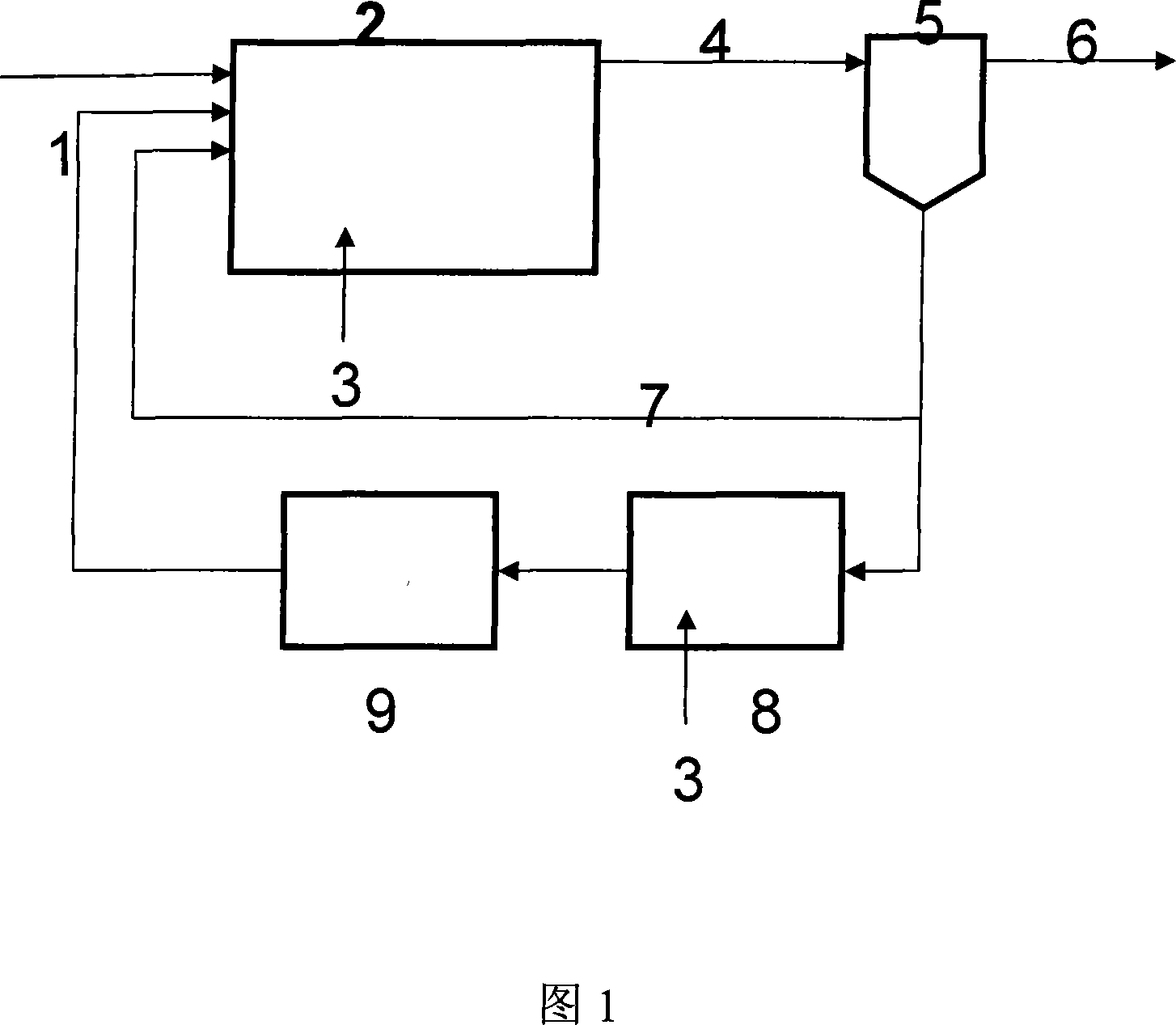

Method used

Image

Examples

Embodiment 1

[0021] Import the sludge discharged from the final sedimentation tank into the sludge pretreatment tank for aeration, control the dissolved oxygen at about 2.0 mg / l, and aerate for 2 hours. Then send it to the precipitation tower to concentrate it by 1 time, send it to the mixing tank, add NaOH liquid to adjust the pH value to 10.6, and then send it to the ultrasonic reactor at 1.34W / cm 2 Sludge wall breaking was carried out for 10 minutes under the sound energy density. After the wall is broken, it is sent to the biological hydrolysis tank for hydrolysis, and then sent to the aeration tank of the sewage treatment process for biological decomposition. Results Compared with the system without aeration, under the condition of the same wall-breaking effect, the amount of alkali is reduced by 35%, and the operating cost is reduced.

Embodiment 2

[0023] The sludge discharged from the final sedimentation tank is introduced into the sludge thickening tank, and the concentrated sludge is sent to the sludge pretreatment tank for aeration, and the dissolved oxygen is controlled at about 1.5mg / l for 2.5 hours of aeration. Then send it to the sedimentation tower to further concentrate it, then send it to the reactor to react with the incoming ozone to break the wall, after the wall breaking is completed, send it to the biohydrolysis tank for hydrolysis, and then send it to the exposure of the sewage treatment process The gas pool is used for biological decomposition.

Embodiment 3

[0025] Import the sludge discharged from the final sedimentation tank into the sludge pretreatment tank for aeration, control the dissolved oxygen at about 4.5mg / l, and aerate for 15 minutes. Then send it to the sedimentation tower to concentrate it, then send it to the reaction tank, add NaOH liquid to adjust the pH value to 11 and heat it to 50°C to break the sludge wall, and send it to the aeration tank of the sewage treatment process after the wall breaking is completed. Biodegradation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com