High strength multilayer laminates comprising twisted nematic liquid crystals

A twisted nematic, liquid crystal technology, applied in the direction of liquid crystal materials, layered products, synthetic resin layered products, etc., can solve the problems of sacrificing visual transparency of windows and damaging windows.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment PE1

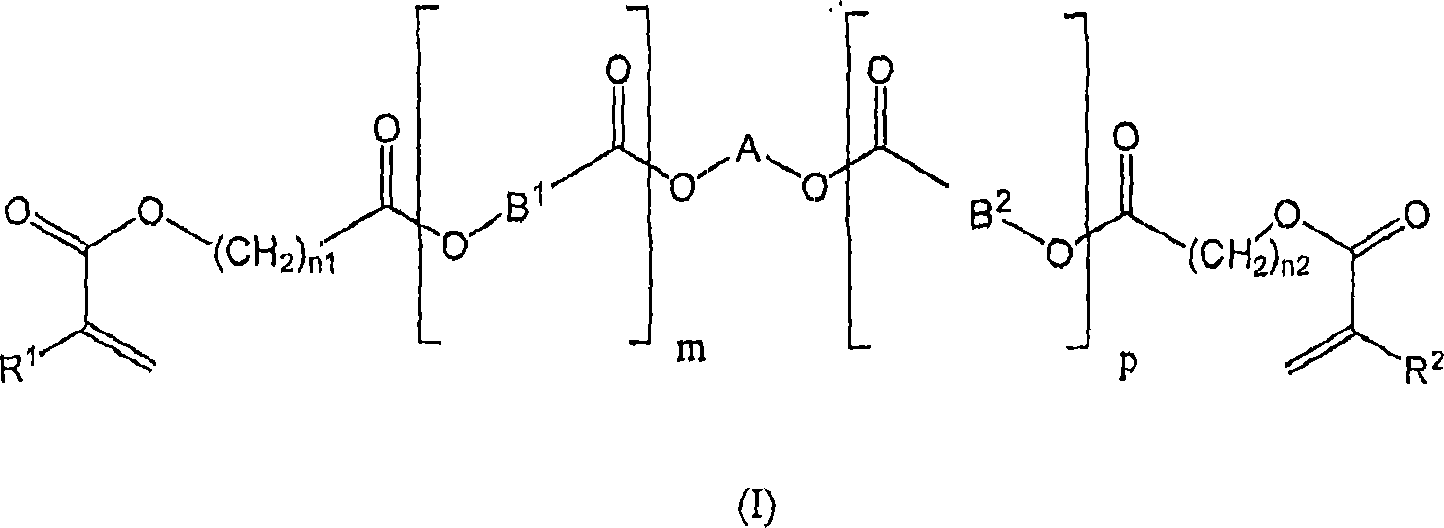

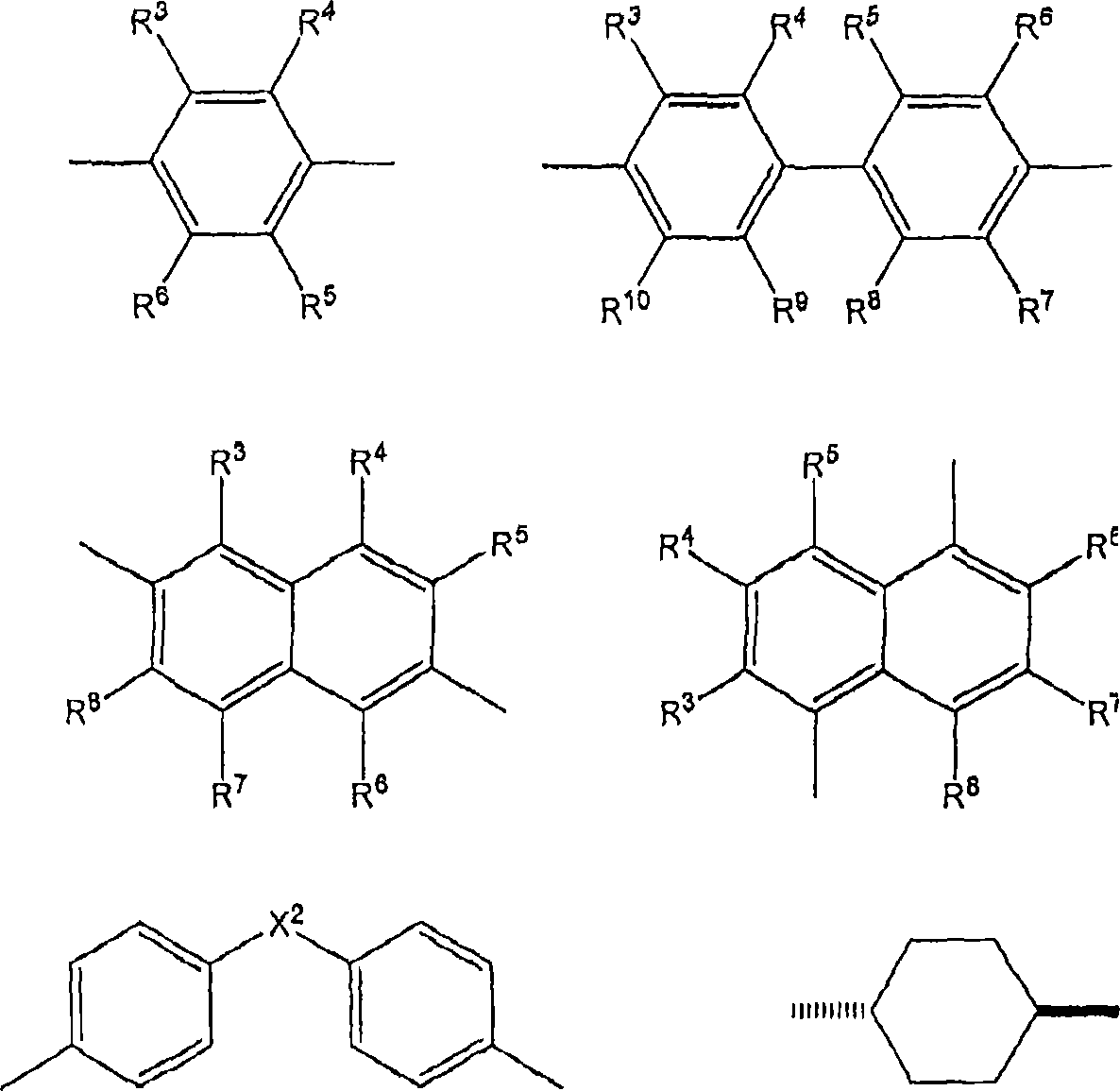

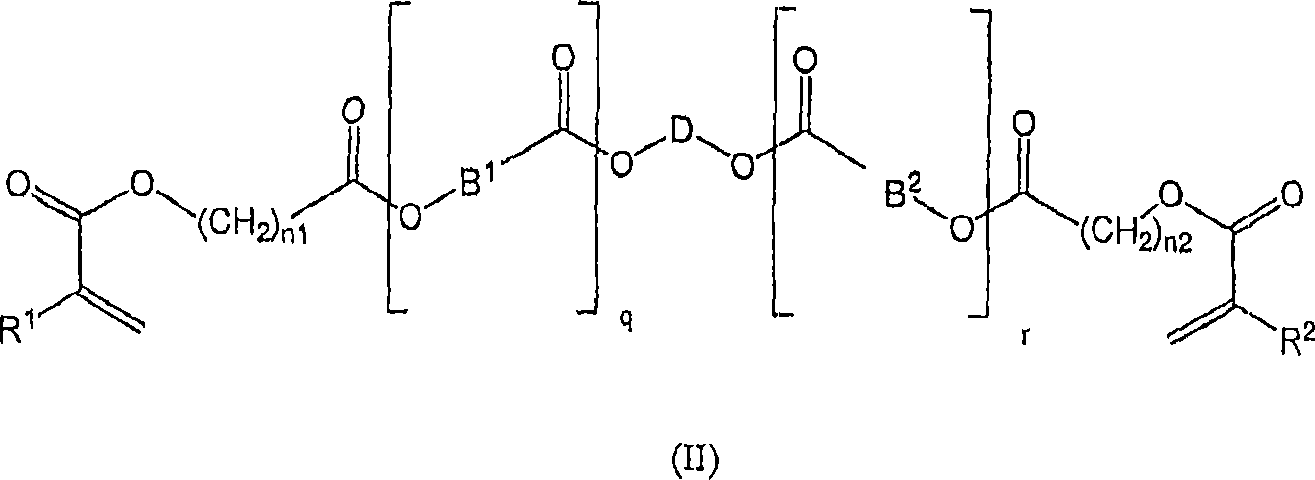

[0118] It will be composed of 48 parts by weight of the following composition structure and wherein R 1 is H and A is -((CH 2 ) 5 )-cholesteryl ester compounds,

[0119]

[0120] 48 parts by weight have the same composition structure as above and wherein R 1 is H and A is -((CH2 ) 2 )-O-cholesteryl ester compound, 3 parts by weight of trimethylolpropane triacrylate and 1 part by weight of Irgacure TM 651 photoinitiator (Ciba Specialty Chemicals, Basel, Switzerland), mixed together to form a colorless solution. The resulting solution was coated onto a friction and orientation layer treated clear annealed float glass substrate (6 inches x 12 inches x 2.5 mm thick) using doctor blade coating. The coating was cured by exposing the material to a 450 watt mercury vapor lamp for 30 seconds with the coated side facing the mercury lamp. A non-micelle-like twisted nematic liquid crystal layer on glass was obtained.

preparation Embodiment PE2

[0122] A colorless solution of PE1 was coated onto a rubbed biaxially oriented polyethylene terephthalate film substrate (6 inches by 12 inches by 4 mil (0.004 inch) thick) using knife coating. The coating was cured by exposing the material to a 450 watt mercury vapor lamp for 30 seconds with the coated side facing the mercury lamp. A non-micellar twisted nematic liquid crystal layer on a biaxially oriented polyethylene terephthalate film was obtained.

preparation Embodiment PE3

[0124] A colorless solution of PE1 was applied to a rubbed and flame treated biaxially oriented polyethylene terephthalate film substrate (6 in x 12 in x 4 mil (0.004 in) thick) using doctor blade coating superior. The coating was cured by exposing the material to a 450 watt mercury vapor lamp for 30 seconds with the coated side facing the mercury lamp. A non-micelle-like twisted nematic liquid crystal layer on a flame-treated biaxially oriented polyethylene terephthalate film was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com