Concentrated low-viscosity rhamnolipid compositions

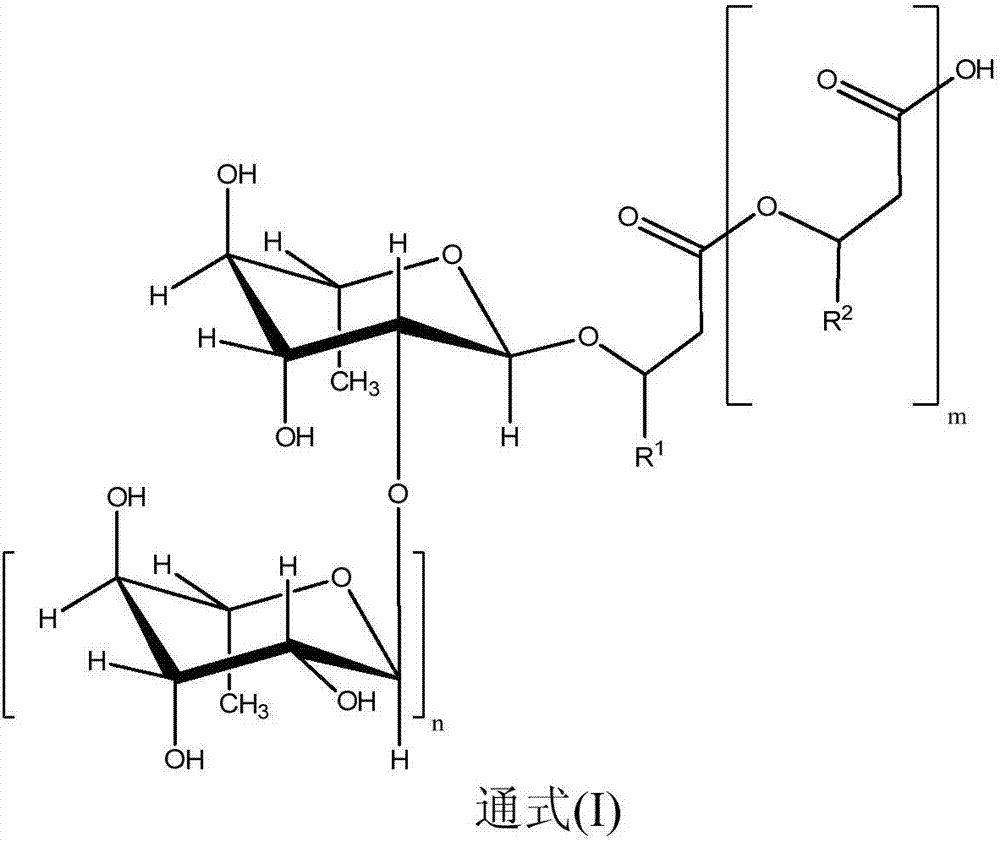

A technology for rhamnolipid and composition is applied in the field of providing concentrated rhamnolipid composition and its preparation, which can solve problems such as viscosity decrease and microbial stability reduction, so as to reduce foaming tendency and increase microbial stability. , clean and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Embodiment 1: the preparation of high concentration RL solution:

[0110] Fermentation was performed using Pseudomonas putida strain pBBR1MCS2-Plac-rhlABC-T-Ptac-rhIC-T, the preparation of which is described in US2014296168, which contains the rhamnolipid biosynthesis genes RhIA, RhIB and RhIC. Preculture was performed in shake flasks as described in WO2012013554A1. For the main culture, mineral medium (M9) was also used. Fermentations were carried out in a carbon-limited manner with glucose feed input in 2 liter fermentors. Glucose feed input was made with reference to the dissolved oxygen signal. Dissolved oxygen was adjusted at 20% saturation by stirrer speed. Pass the pH electrode and add NH 4 SO 4 Adjust the pH to 7. In order to prevent excessive foaming of the fermentation broth, add antifoaming agent DOW Corning1500 as needed. Fermentation was carried out to a dry biomass of 15 g / l within 4 days. The rhamnolipid concentration was determined by HPLC and wa...

Embodiment 2

[0111] Example 2: Partial neutralization with KOH:

[0112] A 50% by weight aqueous KOH solution was added with continuous stirring to the pasty suspension of the concentrated rhamnolipid precipitate (see previous examples) and adjusted to a pH of 5.6. At this point, the pasty substance liquefies, accompanied by a sharp drop in viscosity. A clear solution was obtained from the suspension. 3 aliquots were taken from this solution and adjusted to pH = 6, pH = 7 and pH = 8.5 respectively by addition of additional KOH. After adjusting the pH of the solutions, they were adjusted to 50% by weight, 40% by weight, 30% by weight, 20% by weight and 10% by weight of rhamnolipids by adding water, and used to measure the viscosity. The results are shown in Table 1. It was found possible to obtain a substantially liquid thin and highly concentrated product by partial neutralization. At the same time, dilution of the solution at pH 5.6 and 6 occurs with significantly lower viscosity redu...

Embodiment 3

[0115] Example 3: Partial neutralization with NaOH:

[0116] Partial neutralization was performed similarly to Example 2, except that a 50% by weight NaOH solution was used instead of KOH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com