A novel lithium Fe battery and its making technology

A battery and lithium-iron technology, which is applied in the new lithium-iron battery and its manufacturing process belongs to the field of batteries, which can solve problems such as surplus and unfavorable battery safety, and achieve the effects of enhanced conductivity, reduced safety hazards, and increased direct contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

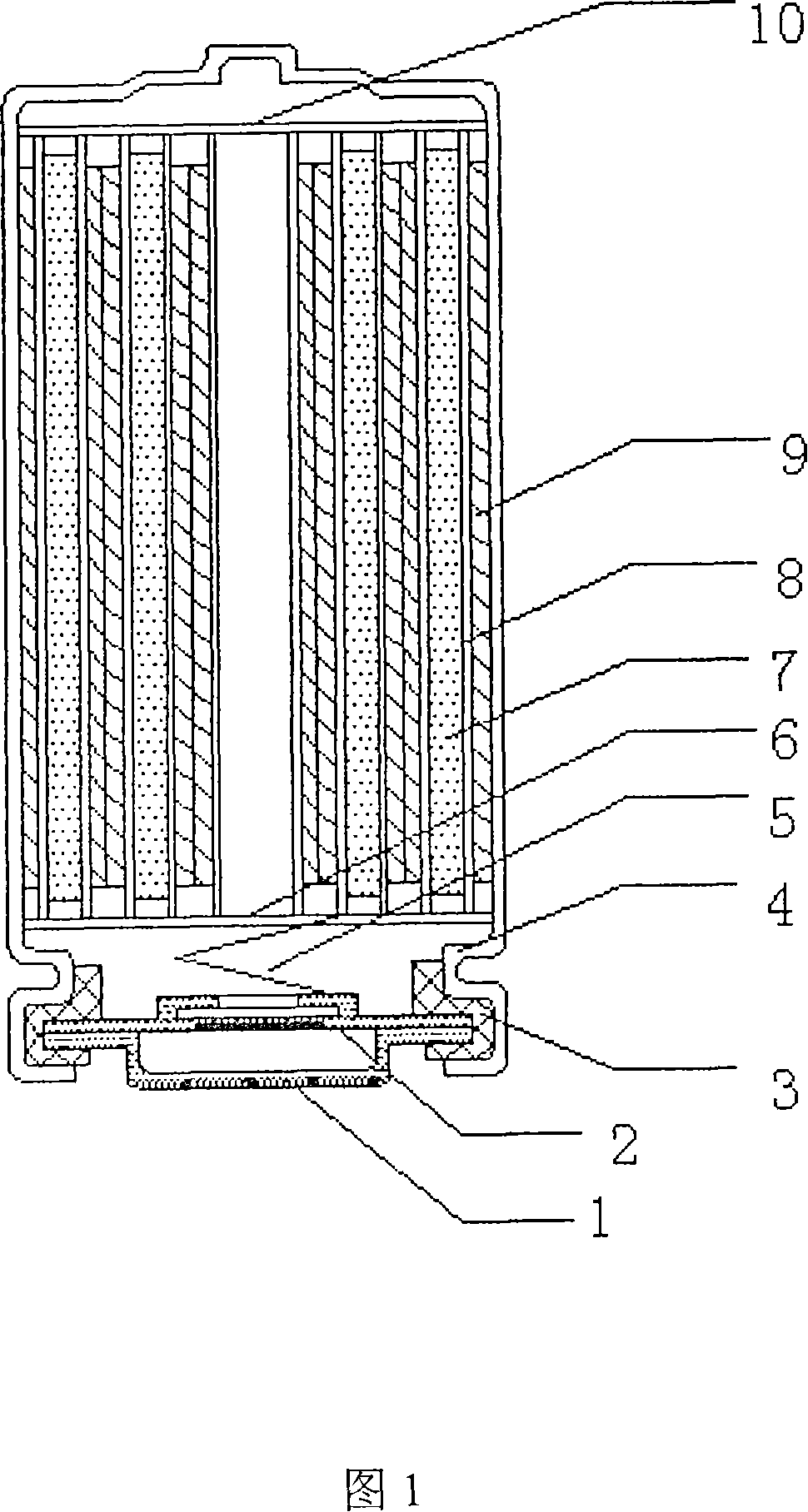

[0023] 100g of iron disulfide positive electrode powder particles pass 325 mesh, 6g of PVDF polyvinylidene fluoride, 6g of conductive additive carbon black, add nitrogen methyl pyrrolidone (NMP) and disperse evenly with a vacuum mixer, so that the viscosity of the slurry is at 5000 cps about. The dispersed positive electrode active material slurry is coated on the aluminum foil, and one side of the aluminum foil is not coated. After drying to remove the solvent, it is cut into a suitable size and rolled so that the solid powder material is firmly attached to the aluminum foil as the positive electrode sheet of the battery. Dimensions of the positive pole piece (mm): 280×40; the size of the coated part on one side (mm): 250×40; the size of the coated part on the other side (mm): 280×40.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com