Method for forming metal composite titanium dioxide nano particle film on glass surface

A metal composite and titanium dioxide technology, which is applied in the field of forming metal composite titanium dioxide nanoparticle films on glass surfaces, can solve the problems of affecting the photocatalytic activity of titanium dioxide particles, low degree of crystallization, short hydrophilic retention time of titanium dioxide films, etc. Effect of particle growth, good photocatalytic performance, improved optical performance and photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

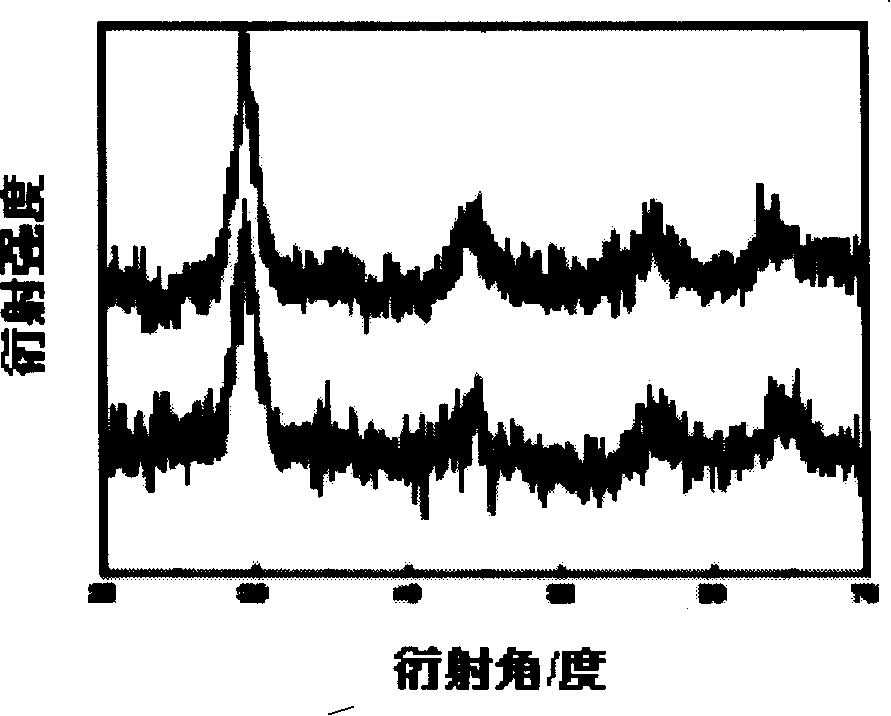

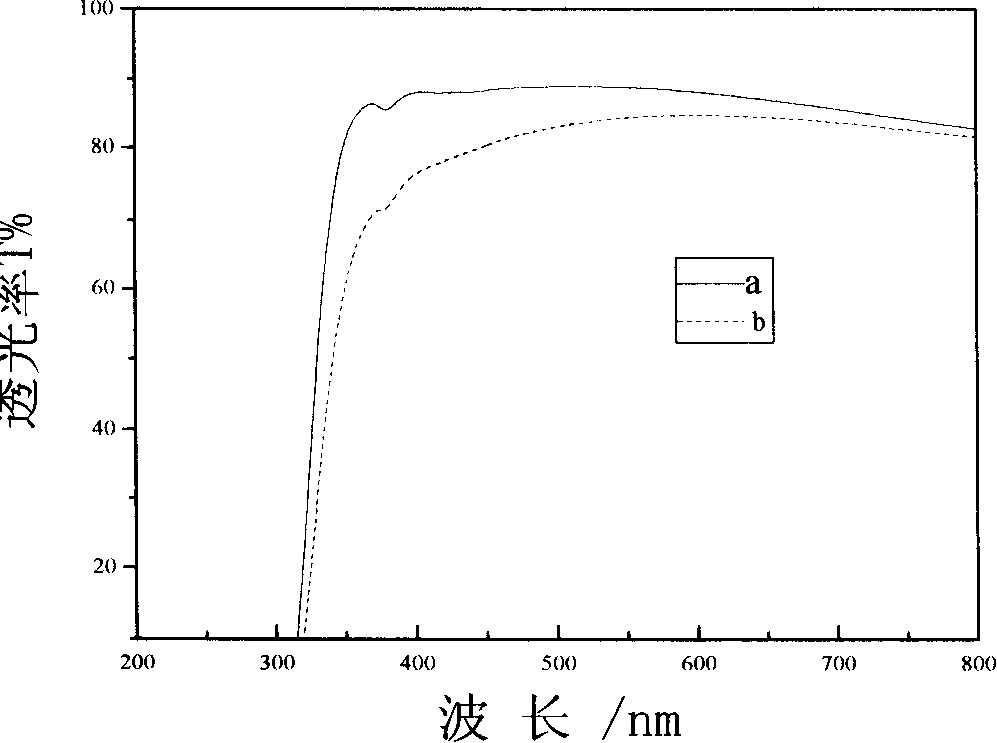

[0056] Dissolve 25 parts by weight of titanium tetrachloride in 75 parts by weight of ice water, and keep stirring for 30 minutes in an ice-water bath at 0-5° C. to obtain a transparent and clear aqueous solution of titanium tetrachloride. 1 part by weight of ferric trichloride is dissolved in 99 parts by weight of deionized water to generate an aqueous solution of iron salt. Add 25 parts by weight of sodium hydroxide to 75 parts by weight of deionized water to obtain an alkaline solution. Under rapid stirring, add 20 parts by weight of iron salt aqueous solution to 40 parts by weight of the above-mentioned titanium tetrachloride aqueous solution, after continuing to stir for several minutes, add 10 parts by weight of alkali solution, after continuing to stir for 10 minutes, add 30 parts deionized water, stirred evenly, transferred into a polytetrafluoroethylene-lined medium pressure autoclave, kept at a constant temperature of 150°C for 2 hours, and cooled naturally to room t...

Embodiment 2

[0059] Dissolve 60 parts by weight of titanium tetrachloride in 40 parts by weight of ice water, and keep stirring for 2 hours in an ice-water bath at 0-5° C. to obtain a transparent and clear aqueous solution of titanium tetrachloride. 2 parts by weight of copper nitrate are dissolved in 99 parts by weight of deionized water to generate a copper salt solution. Add 10 parts by weight of sodium hydroxide to 90 parts by weight of deionized water to obtain an alkaline solution. Under rapid stirring, add 10 parts by weight of copper salt solution to 14 parts by weight of titanium tetrachloride aqueous solution, after continuing to stir for several minutes, add 0.5 parts by weight of alkali solution, add 75.5 parts by weight of deionized water, and continue stirring for 1 After 1 hour, transfer to a polytetrafluoroethylene-lined autoclave, keep the temperature at 100°C for 2 hours, and cool to room temperature naturally. The supernatant was poured off, the lower precipitate was fi...

Embodiment 3

[0062] Dissolve 22 parts by weight of titanium tetrachloride in 78 parts by weight of ice water, keep stirring for 4 hours in an ice-water bath at 0-5°C, and filter to obtain an aqueous solution of titanium tetrachloride; add 0.1 parts by weight of silver nitrate and 5 parts by weight of ammonia water 94.9 parts by weight of deionized water was used to obtain an ammine-complexed silver solution. 37 parts by weight of potassium hydroxide was added to 63 parts by weight of water to obtain an alkaline solution. Under vigorous stirring, add 5 parts by weight of silver solution, 30 parts by weight of alkali solution to 45 parts by weight of the above-mentioned titanium tetrachloride aqueous solution, and then add 20 parts by weight of deionized water. After continuous stirring for 10 minutes, transfer to poly In a tetrafluoroethylene-lined medium-pressure autoclave, keep the temperature at 250°C for 1 hour, and cool down to room temperature naturally. The supernatant was poured of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com